Size-controllable palladium-cuprous oxide nano catalyst as well as preparation method and catalysis application of catalyst

A nano-catalyst and cuprous oxide technology, applied in the field of nano-materials, can solve problems such as complex experimental process, and achieve the effects of good repeatability, good application prospects and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Cuprous Oxide Nanocrystals

[0033] Take 0.085g of copper chloride dihydrate, dissolve it in 50mL of ultrapure water, keep it in a constant temperature water bath at 55°C for half an hour, and keep stirring, then slowly add 5mL of sodium hydroxide solution with a concentration of 2mol / L dropwise, and keep it at a constant temperature for half an hour. Hours, continue to slowly drop 5 mL of ascorbic acid solution with a concentration of 0.6 mol / L, and react for 5 hours. After the reaction, the obtained product was centrifuged, washed repeatedly with ethanol and ultrapure water to obtain a reddish-brown cuprous oxide solid powder, and dried in a vacuum at room temperature for 12 hours to obtain a cuprous oxide nanocrystalline powder.

[0034] The above method for preparing cuprous oxide refers to the method provided by Zhang Dongfeng et al. (Delicate control of crystallographic facet-oriented Cu2O nanocrystals and the correlated adsorption ability. J. Mater...

Embodiment 2

[0036] With the mass fraction of 0.01% Pd as the carrier, the size of the obtained product and the selective hydrogenation activity of acetylene

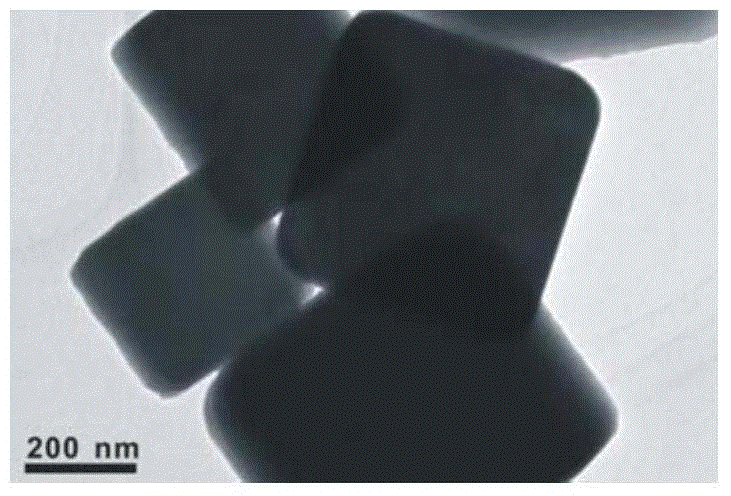

[0037] Put 10-200mg of cuprous oxide synthesized by liquid phase reduction into a glass container, add absolute ethanol and ultrapure water, and add Pd / Cu under stirring conditions 2 O mass ratio of 0.01% PdCl 2Solution, after adding the solution, continue to stir for another half an hour, then carry out high-speed centrifugation to the obtained solution, and dry in a vacuum drying oven (without setting the temperature). Due to the low percentage of palladium loaded, in the transmission electron microscope ( figure 1 ) and no apparent particles about the palladium species.

[0038] The relevant catalytic performance test is done to the product obtained in the present embodiment below:

[0039] The selective hydrogenation reaction of acetylene is carried out in a quartz reaction tube. 20-200 mg of catalyst is added to the quartz r...

Embodiment 3

[0041] With the mass fraction of 0.05% Pd as the carrier, the size of the obtained product and the selective hydrogenation activity of acetylene

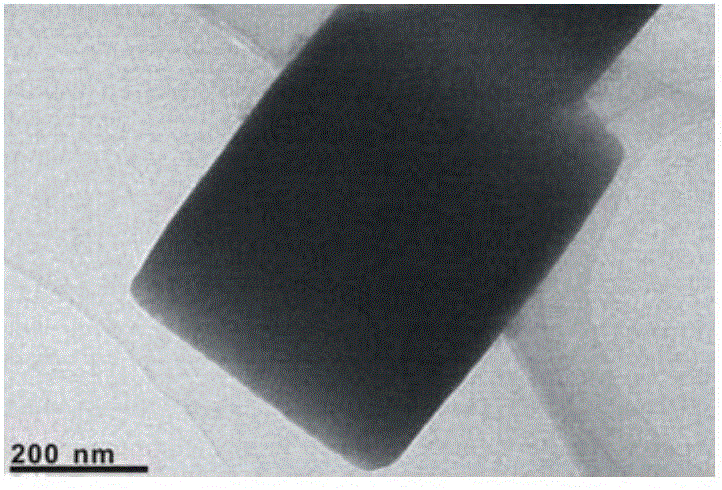

[0042] Put 10-200mg of cuprous oxide synthesized by liquid phase reduction into a glass container, add absolute ethanol and ultrapure water, and add Pd / Cu under stirring conditions 2 O mass ratio of 0.05% PdCl 2 Solution, after adding the solution, continue to stir for another half an hour, then carry out high-speed centrifugation to the obtained solution, and dry in a vacuum drying oven (without setting the temperature). Due to the low percentage of palladium loaded, in the transmission electron microscope ( figure 2 ) and no apparent particles about the palladium species.

[0043] The relevant catalytic performance test is done to the product obtained in the present embodiment below:

[0044] The selective hydrogenation reaction of acetylene is carried out in a quartz reaction tube. 20-200 mg of catalyst is added to the quartz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com