Co2SnO4/C nano-composite negative electrode material for lithium ion battery, preparation and application of Co2SnO4/C nano-composite negative electrode material

A lithium-ion battery and nano-composite technology, applied in the field of electrochemistry, can solve the problems of impossibility for industrial application, long reaction time, and small output, and achieve good cycle stability and rate performance, high specific capacity, and improved conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] To prepare the lithium-ion battery negative electrode sheet, the specific steps are as follows:

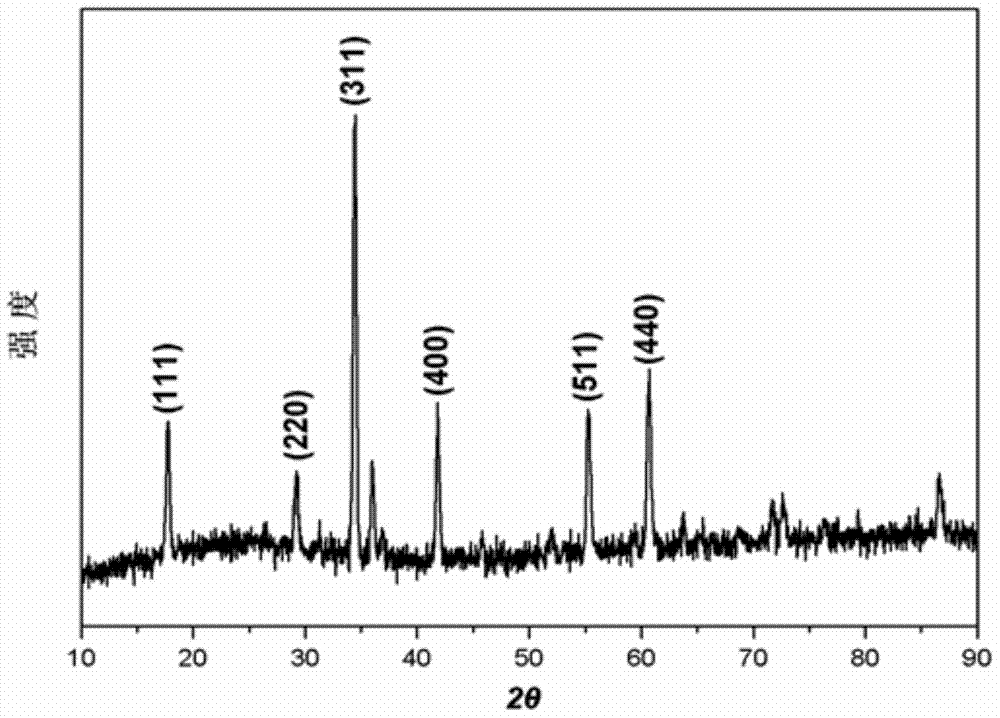

[0044] (1) Preparation of Li-ion battery Co 2 SnO 4 / C nanocomposite anode material:

[0045] (1) Dissolve 0.875g of tin chloride pentahydrate and 1.19g of cobalt chloride hexahydrate in 50mL of deionized water to obtain a dispersion, and then add it to the dispersion under stirring (100r / min) at a speed of 5mL / min Add 50 mL of sodium hydroxide solution dropwise to ensure that the concentration of NaOH in the solution after the dropwise addition is 2 mol / L. After the dropwise addition, continue to stir and react for 10 minutes, then centrifuge the reaction solution to take the precipitate, and dry the resulting precipitate in vacuum at 60°C for 12 hours to obtain a powder; wherein, the molar concentration of tin ions in the dispersion is 0.05mol / L, and the molar concentration of cobalt ions is 0.1mol / L, the molar ratio of tin ions to cobalt ions is 1:2;

[0046] (2) Put...

Embodiment 2

[0052] To prepare the lithium-ion battery negative electrode sheet, the specific steps are as follows:

[0053] (1) Preparation of Li-ion battery Co 2 SnO 4 / C nanocomposite anode material:

[0054] (1) Dissolve 0.875g of tin chloride pentahydrate and 1.19g of cobalt chloride hexahydrate in 50mL of deionized water to obtain a dispersion, and then add it to the dispersion under stirring (250r / min) at a speed of 10mL / min Add 50 mL of sodium hydroxide solution dropwise to ensure that the concentration of NaOH in the solution after the dropwise addition is 2 mol / L. After the dropwise addition, continue to stir and react for 10 minutes, then centrifuge the reaction solution to take the precipitate, and dry the precipitate in vacuum at 70°C for 10 hours to obtain a powder; wherein, the molar concentration of tin ions in the dispersion is 0.05mol / L, and the molar concentration of cobalt ions is 0.1 mol / L, the molar ratio of tin ions to cobalt ions is 1:2;

[0055] (2) Put the pow...

Embodiment 3

[0060] To prepare the lithium-ion battery negative electrode sheet, the specific steps are as follows:

[0061] (1) Preparation of Li-ion battery Co 2 SnO 4 / C nanocomposite anode material:

[0062] (1) Dissolve 0.875g of tin chloride pentahydrate and 1.19g of cobalt chloride hexahydrate in 50mL of deionized water to obtain a dispersion, and then add it to the dispersion under stirring (500r / min) at a speed of 15mL / min Add 50 mL of sodium hydroxide solution dropwise to ensure that the concentration of NaOH in the solution after the dropwise addition is 2 mol / L. After the dropwise addition, continue to stir and react for 10 minutes, then centrifuge the reaction solution to take the precipitate, and dry the precipitate in vacuum at 90°C for 8 hours to obtain a powder; wherein, the molar concentration of tin ions in the dispersion is 0.05mol / L, and the molar concentration of cobalt ions is 0.1 mol / L, the molar ratio of tin ions to cobalt ions is 1:2;

[0063] (2) Put the powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com