Microwave digestion method for the determination of phosphorus / phosphatide content in oil

A technology of phospholipid content and microwave digestion, which is applied in the preparation of test samples, measurement of color/spectral properties, and analysis by chemical reaction of materials, etc., can solve the problems of long ashing time and low detection limit, etc. To facilitate subsequent operations, meet the needs of phospholipid detection, and shorten the analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

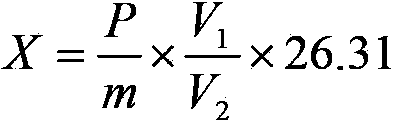

Method used

Image

Examples

Embodiment 1

[0023] precision test

[0024] Weigh 5 samples of Zanthoxylum bungeanum seed oil, put 2.0g each into a polytetrafluoroethylene digestion tank, add 4~8mL of nitric acid and 1~3mL of hydrogen peroxide, shake well, tighten the sealing cap, put the tank into the microwave digestion apparatus, Adjust the power to 800~1000W, and take 7~9min to digest. After the digestion is completed, take out the digestion tank and cool it down, put the digestion solution in a 50m volumetric flask, set volume, and shake well.

[0025] Take the digestion solution in the 10mL volumetric flask and put it in five 50mL volumetric flasks, add 8mL of 0.015% hydrazine sulfate solution and 2mL of ammonium molybdate sulfuric acid solution. Dilute to the mark with deionized water, shake well, and take deionized water as blank at the same time, after standing still for 20min, under the wavelength of 650nm, use Lcm liquid tank to measure its absorbance respectively, and use the standard curve equation to find ...

Embodiment 2

[0029] Recovery test

[0030] Prepare phosphorus standard solutions of three concentrations respectively, add them to soybean oil, measure the phosphorus content therein after mixing, and the operating conditions are the same as the method in Example 1. See Tables 2, 3, and 4 for specific experimental data.

[0031] Table 2 Concentration 1 (phosphorus content about 0.8mg) recovery test results

[0032]

[0033] Table 3 The recovery rate experiment results of concentration 2 (phosphorus content is about 0.4mg)

[0034]

[0035] Table 4 Concentration 3 (phosphorus content about 0.1mg) recovery experimental results

[0036]

[0037] Can illustrate from table 2,3,4, the rate of recovery is between 97.57~101.88%, and the accuracy of the present invention meets detection requirement.

Embodiment 3

[0039] Comparative experiment and comparative experiment of GB5537-2008

[0040] Repeat the above determination according to the GB5537-2008 method, and the specific experimental data are shown in Table 5.

[0041] Table 5GB5537-2008 The recovery rate experiment result of concentration one

[0042]

[0043] The recovery experimental result of table 6GB5537-2008 concentration two

[0044]

[0045] Table 7GB5537-2008 The recovery rate experiment result of concentration three

[0046]

[0047] Table 8 The method and the recovery contrast experiment result of GB5537-2008

[0048]

[0049] It can be shown from the experimental data in Table 8 that the recovery rate measured by the present invention is equivalent to that of GB5537-2008, but its precision is better than the latter at three levels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com