Molecularly imprinted polymer on the surface of carbon nanotubes and its preparation method and application

A surface molecular imprinting, carbon nanotube technology, applied in the direction of material electrochemical variables, can solve problems such as unfavorable business and social development, a large number of pollutants, environmental hazards, etc., to improve electrical conductivity and current response speed, time-consuming, Sensitive high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Example 1 Preparation of molecularly imprinted polymer on the surface of carbon nanotubes

[0086] 1. Preparation of molecularly imprinted polymers on the surface of carbon nanotubes

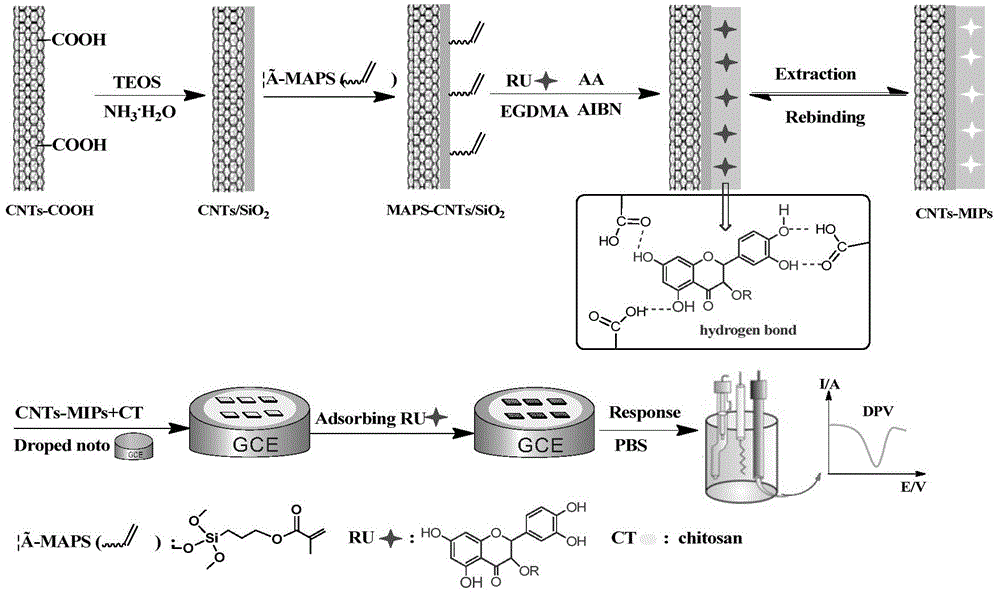

[0087] The preparation process of molecularly imprinted polymer on carbon nanotube surface is as follows figure 1 shown, including the following steps:

[0088] (1) Purification of carboxylated multi-walled carbon nanotubes

[0089] In order to remove a small amount of amorphous carbon and metal impurities in carboxylated multi-walled carbon nanotubes (CNTs), CNTs-COOH was purified. The purification method is as follows:

[0090] In a 100 mL round bottom flask, place 40.0 mL of H 2 O, 9.28mL HNO 3 Mix well, then add 2.0 g CNTs-COOH, and reflux at 85 °C for 48 h. After filtration, the CNTs-COOH was washed with deionized water until neutral, and dried under vacuum at 60 °C for 12 h for use.

[0091] (2) Synthesis of silica-coated multi-walled carbon nanotubes

[0092] Weigh 250.0 mg ...

Embodiment 2

[0112] Example 2 Preparation of electrochemical sensor

[0113] 1. Preparation of electrochemical sensors

[0114] (1) The bare glassy carbon electrode (GCE, 3 mm in diameter) was sequentially used with 0.3 μm and 0.05 μm Al 2 O 3 Powder suspension polishing treatment, and then use absolute ethanol, ddH 2 o Ultrasonic (53KHz) cleaning, 10min each time, finally placed at room temperature to dry, for use;

[0115] (2) Take 20.0 mg γ-MAPS / CNTs@SiO 2 -MIPs were added to 1mL of 0.5% chitosan solution, sonicated at 53KHz for 60min, and the two were mixed evenly to obtain a mixed solution; then 5.0 μL of the mixed solution was applied and dropped on the surface of the bare glassy carbon electrode treated in step (1). After drying at room temperature for 6 hours, the imprinted electrode (γ-MAPS / CNTs@SiO) was obtained. 2 -MIPs / GCE);

[0116](3) Take the imprinted electrode of step (2) as the working electrode, take the saturated calomel electrode as the reference electrode, take ...

Embodiment 3

[0147] Example 3 Detection of actual samples by electrochemical sensors

[0148] In order to investigate the detection feasibility of the electrochemical sensor of the present invention, the actual sample rutin tablet was detected.

[0149]First, use a mortar to grind commercially available rutin tablets, and then use ethanol to ultrasonically dissolve them completely to obtain a rutin tablet dissolving solution; take an appropriate amount of the upper rutin tablet dissolving solution and use PBS buffer (pH 4.5) Dilute to 5mL. Then, the imprinted electrode was immersed in the above diluent, stirred and adsorbed for 7 min, and DPV detection was carried out. Each sample was tested 5 times in parallel, and the average value was taken.

[0150] Table 2

[0151]

[0152] It can be seen from Table 2 that the detection value of the imprinted electrode is basically consistent with the marked value, the recovery rate is 99.5%-100.5%, and the relative standard deviation is 1.9%-2.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com