Method for preparing nano structure of columbite-type metal niobate

A technology of nanostructure and niobate, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high production cost, complex process equipment, large energy consumption, etc., and achieve low production cost, simple process, Mix well and evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

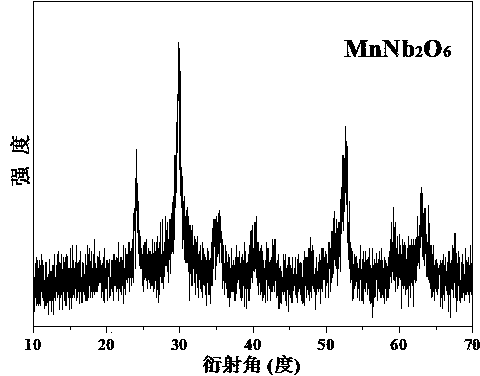

[0021] Embodiment 1: manganese niobate (MnNb 2 o 6 ) preparation.

[0022] 1) Heat and melt 10g of potassium hydroxide in a nickel crucible, then slowly add 2g of niobium pentoxide, cool to room temperature after the reaction is complete, dissolve the obtained substance in 150mL of distilled water, remove undissolved matter by filtration, and dissolve the obtained clear solution Heat and evaporate at 90°C to obtain needle-like crystals, filter and wash with a mixed solution of ethanol and water (volume ratio 1:1), and dry to obtain the precursor of potassium hydrogen hexaniobate.

[0023] 2) Weigh 0.6 mmol of manganese chloride and 0.2 mmol of potassium hydrogen hexaniobate precursor, and dissolve them in 10 mL of distilled water respectively. Under magnetic stirring, the manganese chloride solution was gradually added dropwise to the potassium hydrogen hexaniobate solution to form a suspension.

[0024] 3) Transfer the obtained suspension to a hydrothermal reaction kettle,...

Embodiment 2

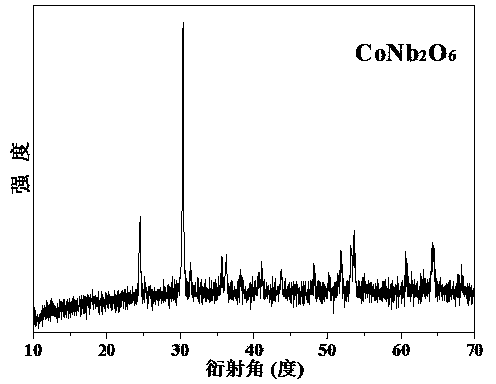

[0026] Embodiment 2: cobalt niobate (CoNb 2 o 6 ) preparation.

[0027] 1) Heat and melt 10g of potassium hydroxide in a nickel crucible, then slowly add 2g of niobium pentoxide, cool to room temperature after the reaction is complete, dissolve the obtained substance in 150mL of distilled water, remove undissolved matter by filtration, and dissolve the obtained clear solution Heat and evaporate at 90°C to obtain needle-like crystals, filter and wash with a mixed solution of ethanol and water (volume ratio 1:1), and dry to obtain the precursor of potassium hydrogen hexaniobate.

[0028] 2) Weigh 0.6 mmol of cobalt chloride and 0.2 mmol of potassium hydrogen hexaniobate precursor, and dissolve them in 10 mL of distilled water respectively. Under magnetic stirring, the cobalt chloride solution was gradually added dropwise to the potassium hydrogen hexaniobate solution to form a suspension.

[0029] 3) Transfer the obtained suspension to a hydrothermal reaction kettle, add dist...

Embodiment 3

[0031] Embodiment 3: nickel niobate (NiNb 2 o 6 ) preparation.

[0032] 1) Heat and melt 10g of potassium hydroxide in a nickel crucible, then slowly add 2g of niobium pentoxide, cool to room temperature after the reaction is complete, dissolve the obtained substance in 150mL of distilled water, remove undissolved matter by filtration, and dissolve the obtained clear solution Heat and evaporate at 90°C to obtain needle-like crystals, filter and wash with a mixed solution of ethanol and water (volume ratio 1:1), and dry to obtain the precursor of potassium hydrogen hexaniobate.

[0033] 2) Weigh 0.6mmol of nickel chloride and 0.2mmol of potassium hydrogen hexaniobate precursor, and dissolve them in 10mL of distilled water respectively. Under magnetic stirring, the nickel chloride solution was gradually added dropwise to the potassium hydrogen hexaniobate solution to form a suspension.

[0034] 3) Transfer the obtained suspension to a hydrothermal reaction kettle, add distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com