Method for minimizing fatigue damage in welded structure, tool for forming strike mark, and welded structure

A fatigue damage and welded structure technology, applied in welding/welding/cutting items, manufacturing tools, welding equipment, etc., can solve problems such as fatigue cracks, and achieve the effect of suppressing fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

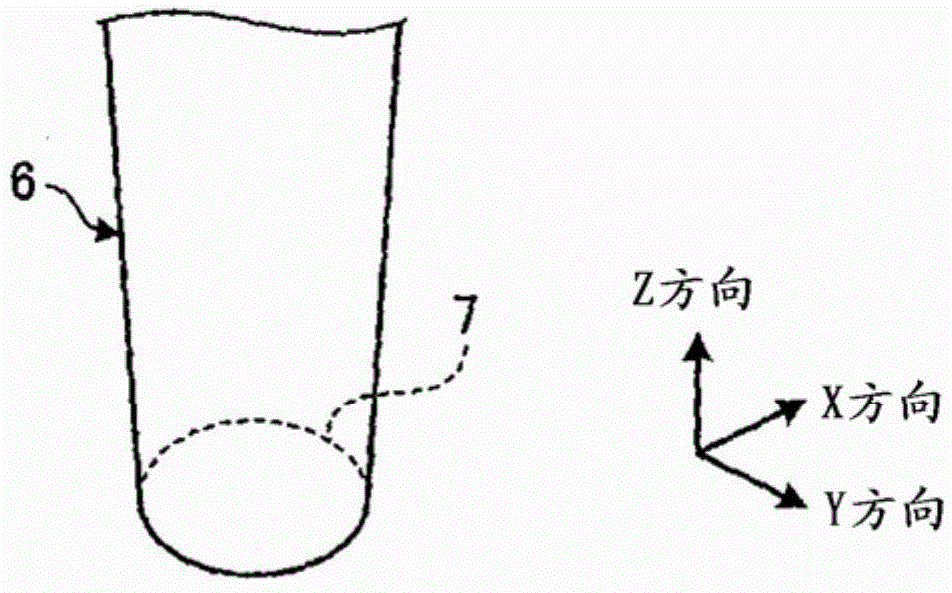

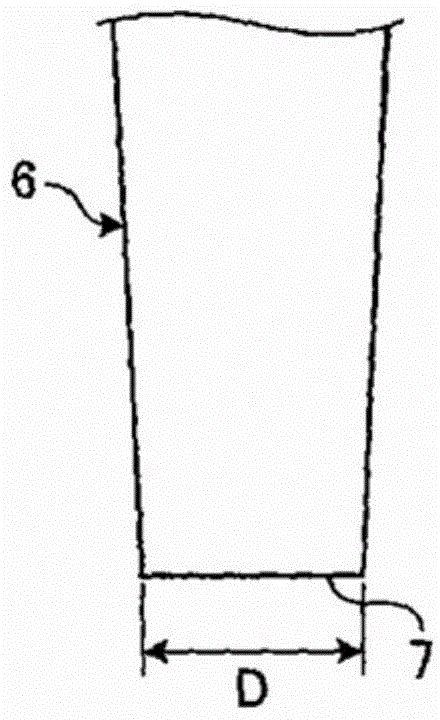

[0057] The tool 6 for forming a blow mark used when implementing the fatigue damage suppression method of a welded structure according to the first embodiment of the present invention is also made of high-strength steel (high-strength steel) (SM570 grade or higher) with a tensile strength of 600 MPa or more at least. ) formed, and as figure 1 as well as Figure 2A ~ Figure 2C As shown, it has a blow mark forming surface 7 at the front end. The impact mark forming surface 7 is used to form a substantially linear and curved weld seam 3 (refer to Figure 5 ) the surface where the strike mark 5 is formed on the surface of the adjacent base material 1 . Such as Figure 2A ~ Figure 2C As shown, the scratch formation surface 7 is flat and circular with a radius of not less than 1.5 mm and not more than 3.0 mm, that is, a diameter D of not less than 3.0 mm and not more than 6.0 mm. As the definition of "circle" of the impact mark forming surface 7 formed in a circle, the ratio of ...

Embodiment 1

[0070] The present inventors under the welding conditions (welding condition) that the welding current (welding current) is 280A, the welding voltage (welding voltage) is 32V, and the welding speed (welding speed) is 28cpm, the Figure 6A , Figure 6B The welded joints shown were prepared as test pieces, and a compressive residual stress introduction test was performed under the conditions shown in Table 1 using the prepared welded joints.

[0071] 〔Table 1〕

[0072] [Table 1]

[0073]

[0074] * Residual stress at weld toe: Measurement result of residual stress using X-ray

[0075] Examples 1 to 4 in Table 1 show the following cases: on the surface of the base material 1 adjacent to the weld 3, using the tool 6 for forming a dent with the diameter D of the dent forming surface 7 being 3mm, 4mm, 5mm, or 6mm, Striking marks 5 having a maximum depth of 0.03 mm or more and less than 0.50 mm are continuously formed along the weld seam 3 . Examples 5 to 8 in Table 1 show the...

Embodiment 2

[0081] The present inventors used tools for forming blow marks having the tip shapes shown in Table 2 (Examples 11 to 18 and Comparative Examples 11 to 16), and hammered (air pressure : about 0.588MPa (about 6kg / cm 2 ), frequency: 90Hz, moving speed: 0.25mm / sec), vertically strike marks along the welding line throughout the length of 100mm and strike repeatedly with tools so that the distance from the weld toe of the weld to the base metal side is 5mm The maximum depth of the strike mark in the area is 0.02-0.50 mm, and then, the residual stress at a position 1 mm away from one end of the strike mark 5 (the end on the side of the welding toe 4 ) is measured by X-ray. Take the beam diameter as Measurement of residual stress using X-rays is performed. Table 2 shows the test results.

[0082] 〔Table 2〕

[0083] [Table 2]

[0084]

[0085] * Residual stress at weld toe: Measurement result of residual stress using X-ray

[0086] Examples 11 to 14 in Table 2 show the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com