Manufacturing method of circuit board

A manufacturing method and circuit board technology, applied in printed circuit manufacturing, printed circuit, electrical components, etc., can solve problems such as easy residual air bubbles, affecting detection and repair efficiency, and easy formation of plug hole depressions, so as to eliminate plug hole depressions, The effect of reducing the risk of failure and eliminating hidden dangers in quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

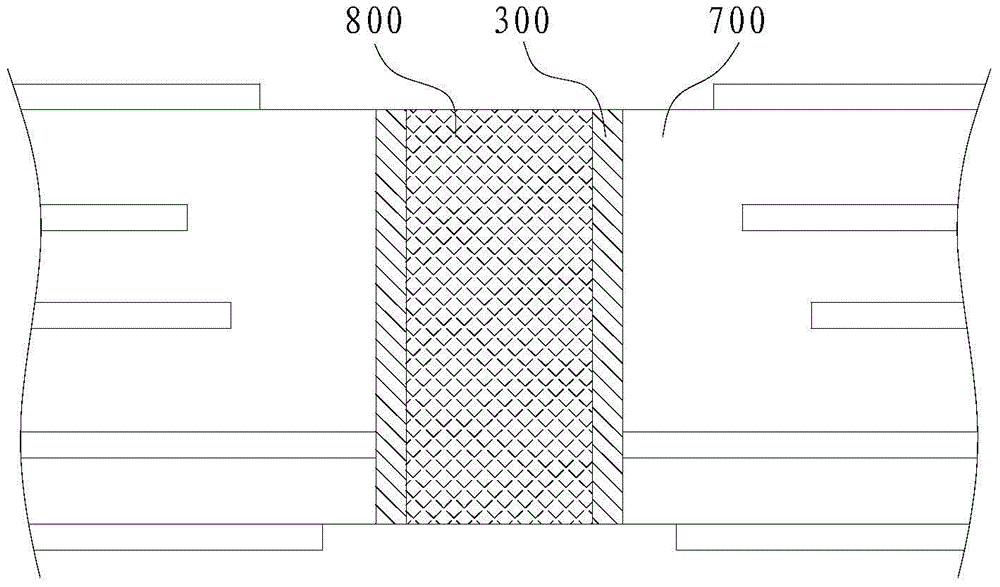

[0050] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0051] Embodiments of the present invention provide a method for manufacturing a circuit board, comprising the following steps:

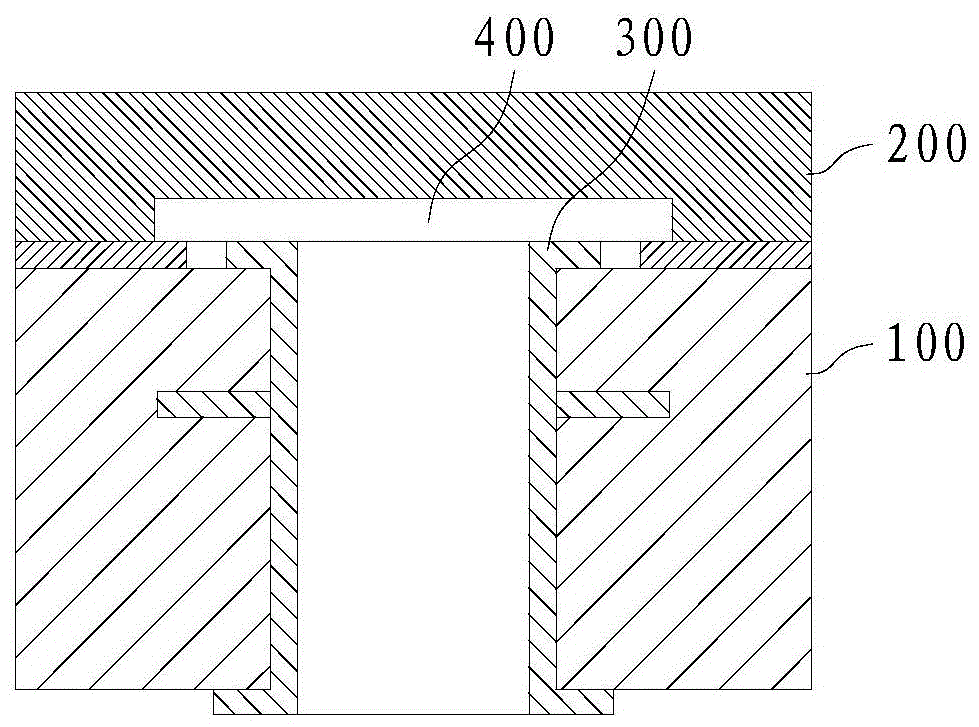

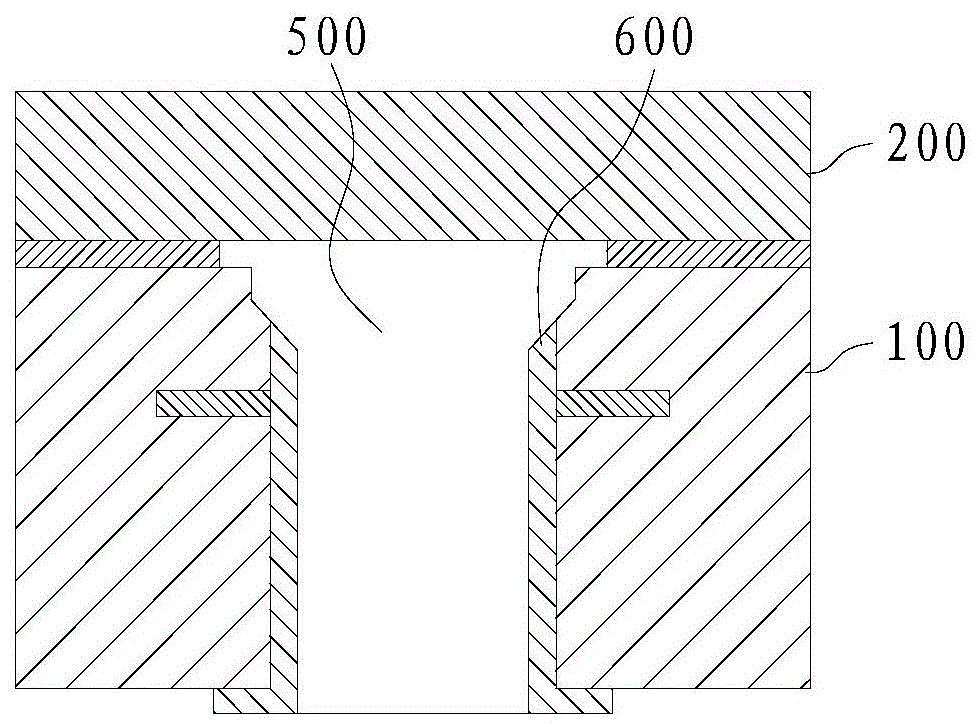

[0052] Step S10: Provide a cover plate, and open a second through hole on the cover plate corresponding to the metallized hole formed on the circuit board through electroplating, the aperture of the second through hole is larger than the aperture of the metallized hole , making the cover plate cover the surface of the circuit board after electroplating, and the second through hole is opposite to the metallized hole of the circuit board;

[0053] Step S20: providing a resin material with good wettability with the copper surface, so that the resin is fully stirred under vacuum conditions;

[0054] Step S30: apply the stirred resin on the surface of the cover plate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com