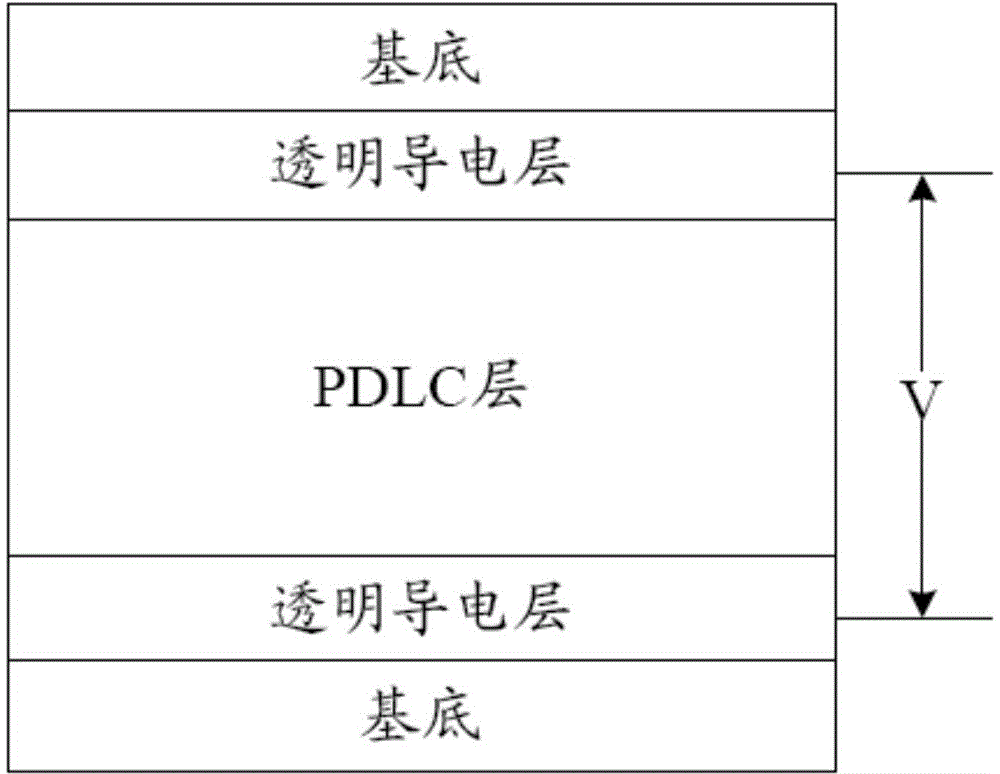

Optical composite membrane based on PDLC (Polymer Dispersed Liquid Crystal) device and preparation method of optical composite membrane

An optical composite film and device technology, applied in the optical field, can solve the problems of increasing coating time and raw material consumption, damage of water vapor barrier film, and increasing production cost, so as to reduce coating time and raw material consumption, reduce production cost, excellent optics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

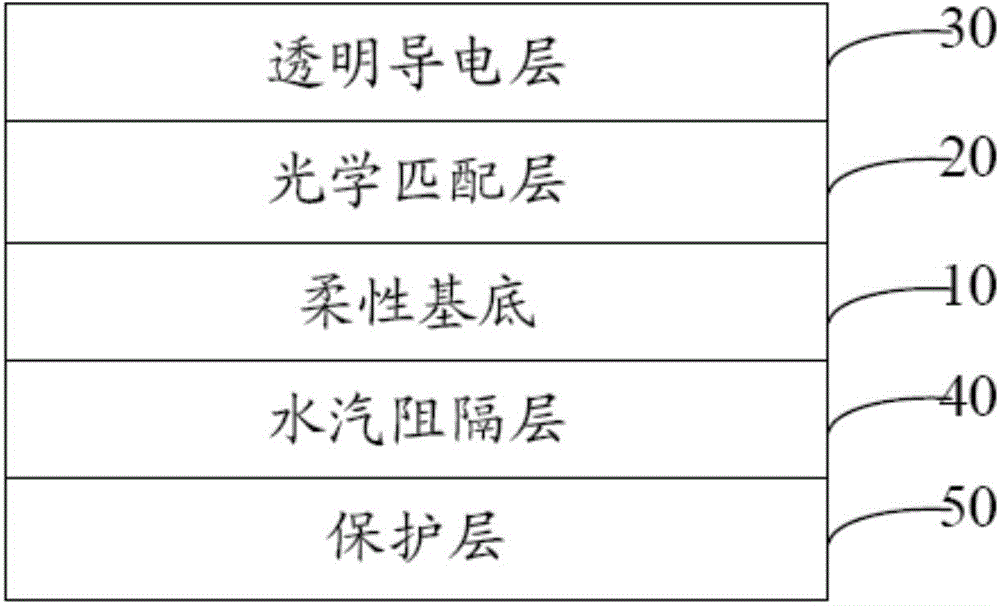

[0036] The invention discloses an optical composite film based on a PDLC device, which sequentially includes a transparent conductive layer, an optical matching layer, a flexible base and a water vapor barrier layer. The flexible base is an organic polymer material, and the water vapor barrier layer is an inorganic oxide.

[0037] Correspondingly, the preparation method of optical composite film comprises:

[0038] S1, providing a flexible substrate;

[0039] S2. Prepare at least one optical matching layer on the flexible substrate by magnetron sputtering;

[0040] S3, preparing a transparent conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com