Method for bonding and splicing seed crystals for monocrystalline silicon ingots and crucible for ingots

A technology similar to single crystal silicon and single crystal silicon, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc. Fleece effect and conversion efficiency, affecting the quality of monocrystalline silicon ingots, etc., to achieve the effects of fewer defects, preventing the generation of dislocation sources, and low dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

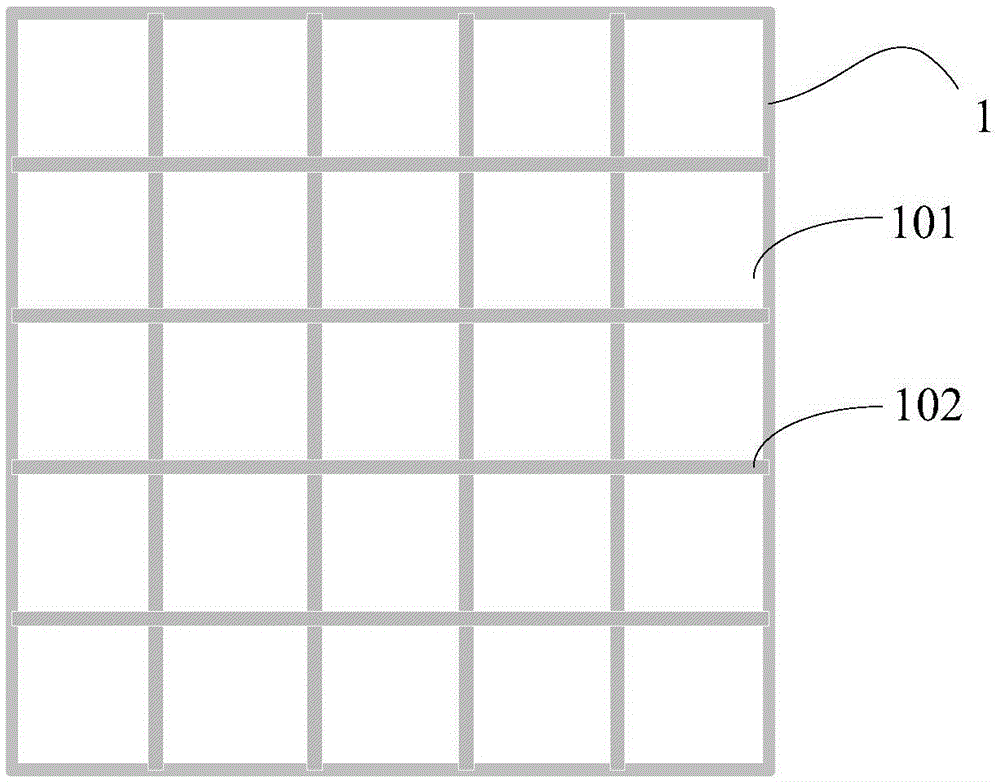

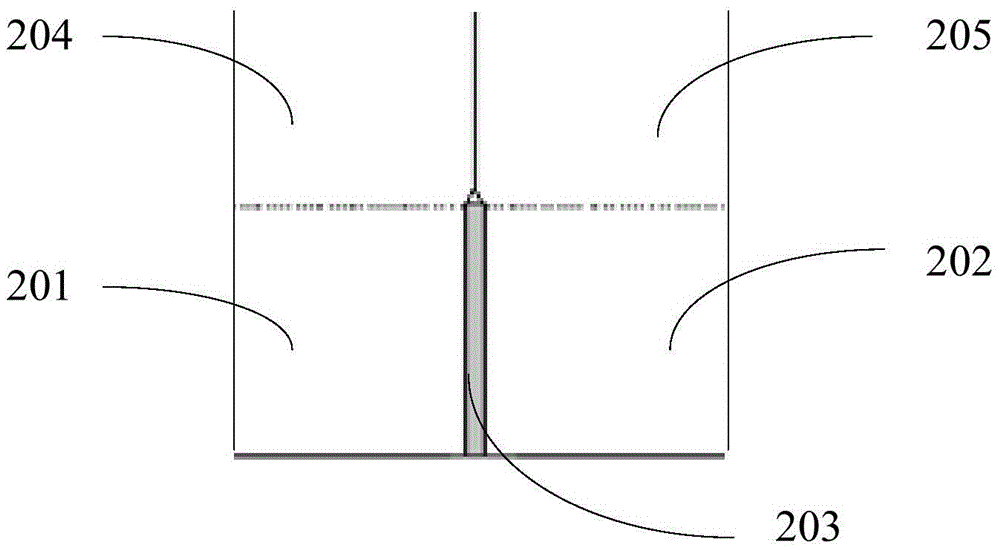

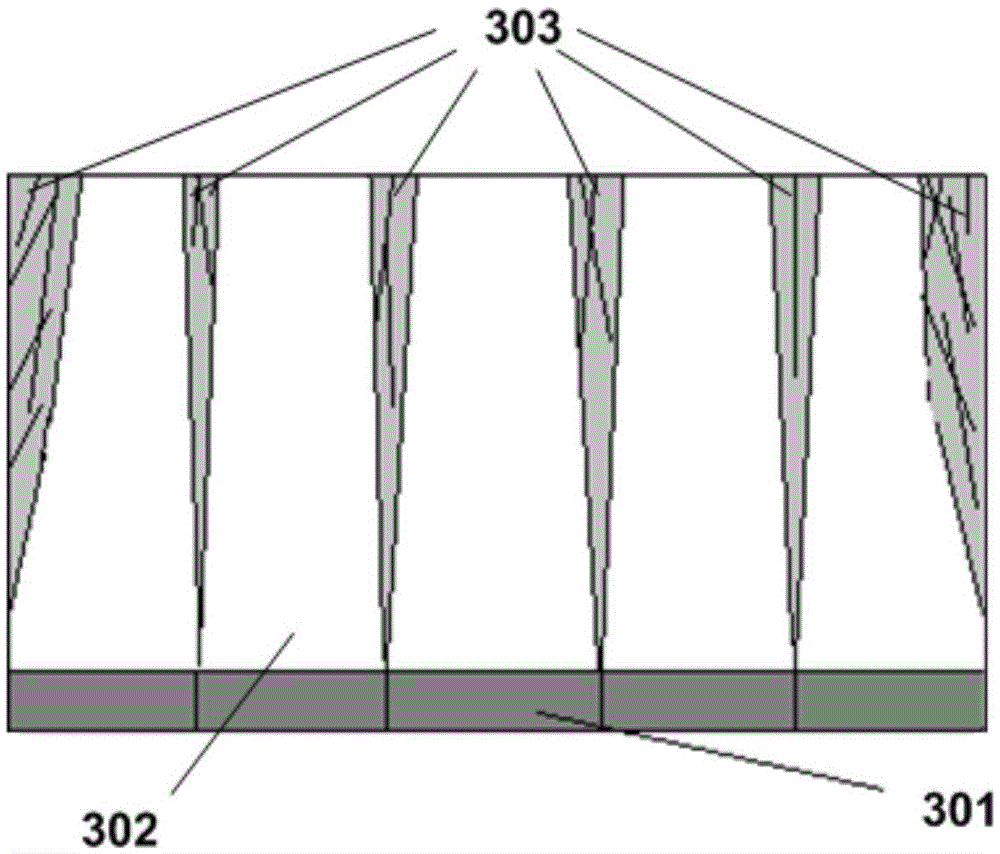

[0049] A method for bonding and splicing seed crystals for quasi-monocrystalline silicon ingots, which is used for directional solidification method quasi-monocrystalline silicon ingots. The specific steps are as follows:

[0050] (1) Cut the seed crystal into a size of 156.8mm×156.8mm, with a thickness of 5mm to 30mm, the size of the seed crystal is not limited to 156.8mm×156.8mm, it can be more or smaller, and the seed crystal preferably has a crystal orientation of (100) Monocrystalline silicon block; after the seed crystal cutting is ready, use an etching method to remove the damaged layer on the surface to be spliced; the silicon etching solution used in the etching method can be an acid etching solution or an alkali etching solution;

[0051] The acid etching solution is a mixed solution of hydrofluoric acid with a mass fraction of 49% and nitric acid with a mass fraction of 63%, and the volume ratio of hydrofluoric acid and nitric acid in the acid etching solution is 1:3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com