Fluorosilicone modified aqueous pressure-sensitive adhesive used for polyethylene protection film, and preparation method thereof

A polyethylene protective film and fluorine-silicon modification technology, which is applied in the direction of adhesives, ester copolymer adhesives, film/sheet adhesives, etc., can solve the problems of users' health hazards and environmental pollution, and achieve Stable storage and good peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

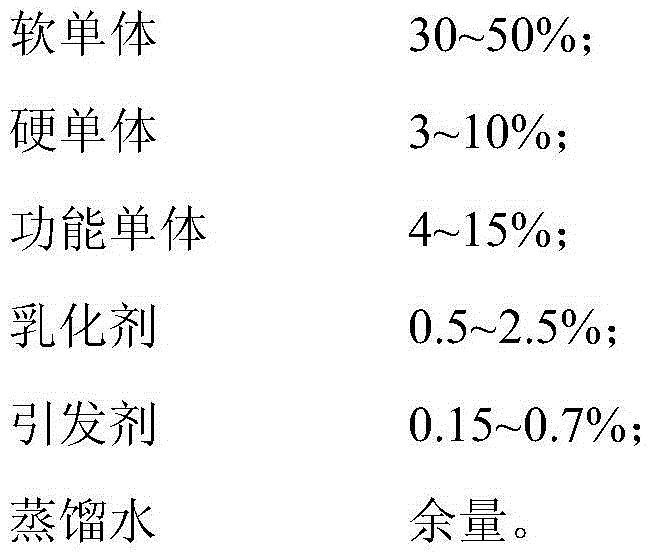

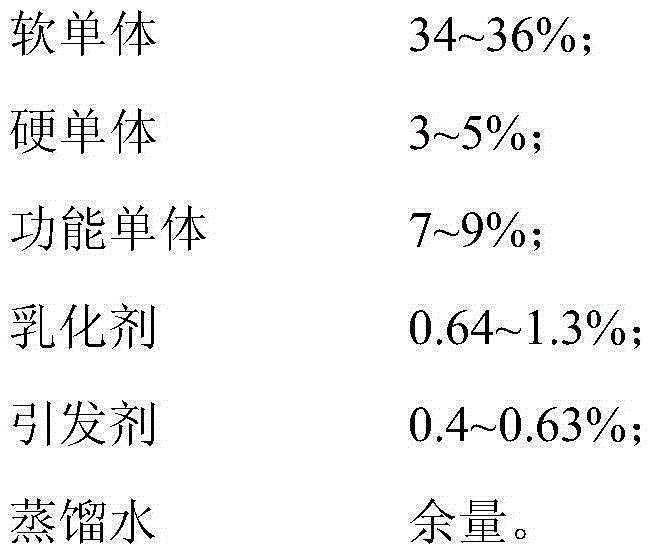

Method used

Image

Examples

Embodiment 1

[0034] 1. Synthetic fluorosilicone emulsion

[0035] 175g isooctyl acrylate, 50g butyl acrylate, 20g methyl methacrylate, 30g vinyl acetate, 3g acrylic acid, 8g vinyltriethoxysilane, 8g trifluoroethyl methacrylate, 2g lauryl sulfate Sodium, 2g sodium diisooctyl succinate, 1g ammonium persulfate and 200g distilled water are mixed and emulsified evenly, add 50g of the above mixture and 120g distilled water into the reactor, and when the temperature rises to 75-85°C, add 1g persulfuric acid Ammonium, after 20 to 40 minutes of polymerization reaction, slowly add the remaining amount of the above mixture in the reflux state, and drop it in 1 to 4 hours; After reaction, the fluorosilicone emulsion is obtained after cooling.

[0036] 2. Preparation of fluorosilicone modified water-based pressure-sensitive adhesive

[0037] Stir 95g of fluorosilicon emulsion and 5g of trifunctional aziridine crosslinking agent evenly at room temperature to prepare the fluorosilicon modified water-ba...

Embodiment 2

[0054] 1. Synthetic fluorosilicone emulsion

[0055] 180g isooctyl acrylate, 40g butyl acrylate, 25g methyl methacrylate, 25g vinyl acetate, 4g acrylic acid, 6g vinyltriethoxysilane, 10g trifluoroethyl methacrylate, 3g lauryl sulfate Sodium, 3g sodium diisooctyl succinate, 1.5g ammonium persulfate and 200g distilled water are mixed and emulsified evenly, and 50g of the above mixture and 120g of distilled water are added to the reactor, and when the temperature rises to 75-85°C, add 0.5g Ammonium persulfate, after 20-40 minutes of polymerization reaction, slowly add the remaining amount of the above mixture dropwise under reflux, and drop it in 1-4 hours; Hours, the reaction was stopped, and the fluorosilicon emulsion was obtained after cooling.

[0056] 2. Preparation of fluorosilicone modified water-based pressure-sensitive adhesive

[0057] Stir 96g of fluorosilicon emulsion and 4g of trifunctional aziridine crosslinking agent evenly at room temperature to prepare the fluo...

Embodiment 3

[0074] 1. Synthetic fluorosilicone emulsion

[0075] 185g isooctyl acrylate, 30g butyl acrylate, 27g methyl methacrylate, 27g vinyl acetate, 4g acrylic acid, 10g vinyltriethoxysilane, 8g trifluoroethyl methacrylate, 4g lauryl sulfate Mix and emulsify sodium, 3g sodium diisooctyl succinate, 1g ammonium persulfate and 200g distilled water evenly, add 50g of the above mixture and 120g distilled water into the reactor, and add 1g persulfuric acid when the temperature rises to 75-85°C Ammonium, after 20-40 minutes of polymerization reaction, slowly add the remaining amount of the above-mentioned mixture dropwise under reflux, and finish dropping in 1-4 hours; The reaction is stopped, and the fluorosilicone emulsion is obtained after cooling.

[0076] 2. Preparation of fluorosilicone modified water-based pressure-sensitive adhesive

[0077] Stir 97g of fluorosilicon emulsion and 3g of trifunctional aziridine crosslinking agent evenly at room temperature to prepare the fluorosilico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com