A kind of preparation method of attapulgite/polyphenylene ether nanocomposite material

A technology of nanocomposite materials and polyphenylene ether, which is applied in the field of nanomaterials to achieve the effects of good compatibility, improved heat resistance, and large internal and external specific surface areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

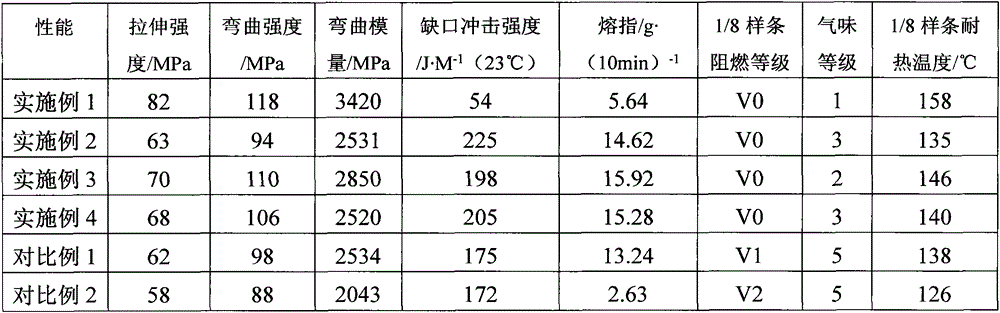

Examples

Embodiment 1

[0028] 1. Preparation of attapulgite slurry: disperse attapulgite powder in water to prepare attapulgite slurry, wherein the mass ratio of attapulgite to water is 0.05:1;

[0029] 2. Chemical modification of attapulgite: Add KH550 dropwise to the attapulgite slurry under constant stirring, wherein the mass ratio of KH550 to attapulgite is 0.05:1, the reaction temperature is 40°C, and the reaction time is 1h. After the reaction, filter, wash, dry at 60°C and pulverize to obtain modified attapulgite;

[0030] 3. Preparation of modified attapulgite slurry: disperse modified attapulgite into methanol to prepare modified attapulgite slurry, wherein the mass ratio of modified attapulgite to methanol is 0.01:1;

[0031] 4. Preparation of attapulgite / polyphenylene ether nanocomposite: put cuprous bromide and dimethylamine into the modified attapulgite slurry, stir continuously, and then dissolve 2,6-xylenol in methanol , added to the modified attapulgite slurry containing the copper ...

Embodiment 2

[0033] 1. Preparation of attapulgite slurry: disperse attapulgite powder in water to prepare attapulgite slurry, wherein the mass ratio of attapulgite to water is 25:100;

[0034] 2. Chemical modification of attapulgite: under continuous stirring, add octadecyltrimethylammonium bromide dropwise to the attapulgite slurry, wherein the mass ratio of octadecyltrimethylammonium bromide to attapulgite is 0.4:1, the reaction temperature is 100°C, and the reaction time is 24h. After the reaction, filter, wash, dry at 120°C and pulverize to obtain modified attapulgite;

[0035] 3. Preparation of modified attapulgite slurry: disperse modified attapulgite in toluene to prepare modified attapulgite slurry, wherein the mass ratio of modified attapulgite to toluene is 0.25:1;

[0036] 4. Preparation of attapulgite / polyphenylene ether nanocomposite: Put cuprous iodide and pyridine into the modified attapulgite slurry, stir continuously, then dissolve 2,6-xylenol and ammonium persulfate in t...

Embodiment 3

[0038] 1. Preparation of attapulgite slurry: disperse attapulgite powder in water to prepare attapulgite slurry, wherein the mass ratio of attapulgite to water is 10:100;

[0039] 2. Chemical modification of attapulgite: Add KH560 dropwise to the attapulgite slurry under constant stirring, wherein the mass ratio of KH560 to attapulgite is 0.1:1, the reaction temperature is 80°C, and the reaction time is 6h. After the reaction, filter, wash, dry at 100°C and pulverize to obtain modified attapulgite;

[0040] 3. Preparation of modified attapulgite slurry: disperse modified attapulgite into 1,4-dioxane to prepare modified attapulgite slurry, wherein modified attapulgite and 1,4-dioxane The mass ratio is 0.1:1;

[0041] 4. Preparation of attapulgite / polyphenylene ether nanocomposite: Put cuprous chloride and n-butylamine into the modified attapulgite slurry, stir continuously, then dissolve 2,6-xylenol and hydrogen peroxide in organic Solvent, and added to the modified attapulgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com