A kind of cross-linked metal supramolecular copolymer self-healing coating material and preparation method thereof

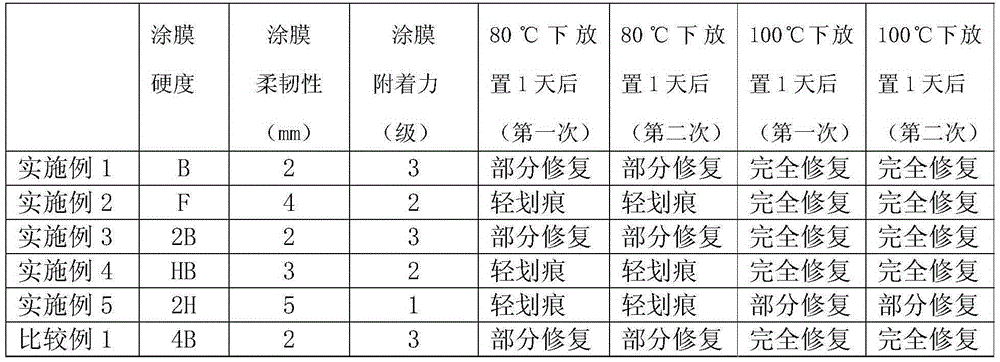

A coating material and supramolecular technology, applied in the coating and other directions, can solve the problems of difficult to meet practical requirements and low hardness of coating materials, and achieve the effect of solving multiple repairs, high repair rate and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) RAFT aggregation. A mixed monomer of 20.28g lauryl methacrylate and 2.07g styrene and 3.65g methacrylate-6-(2,2':6',2"-terpyridine-4'-oxyl) hexyl mono After dissolving the body with 4.00ml of toluene, add it to a 50ml reactor, start stirring, and after 30 minutes of purging oxygen with nitrogen, add 1.15ml of toluene containing 0.1425g of isobutyronitrile dithiobenzoate and 0.0265g of azobisisobutyronitrile Solution. Reacted in an oil bath at 70° C. for 18 hours. Discharged, and the polymer product was purified by precipitation with 250 ml of cold ethanol, and the polymer was obtained after drying.

[0032] Through nuclear magnetic detection, the obtained polymer parameters are: 1HNMR (CDCl3, δppm): 0.82-2.02 (185H), 3.94-4.28 (14H), 6.45-7.09 (8H), 7.40 (1H), 7.88 (1H), 8.04 ( 1H), 8.64-8.72(2H); the NMR data prove that the product obtained is polylauryl methacrylate-styrene-methacrylic acid-6-(2,2':6',2"-terpyridine-4 '-oxygen) hexyl ester terpolymer. The nuclea...

Embodiment 2

[0039] (1) RAFT aggregation. Mixed monomers of 15.07g of 2-ethylhexyl acrylate and 5.03g of ethyl methacrylate and 5.85g of methacrylic acid-8-(2,2':6',2"-terpyridine-4'- Oxygen) octyl ester monomer was dissolved in 12.00ml benzene and added to a 50ml reactor, started to stir, and after 5 minutes of blowing nitrogen to drive oxygen, add 0.2295g cumyl dithiobenzoate and 0.1145g diphenyl peroxide Formyl in 2.50ml of benzene solution. Reacted in an oil bath at 80°C for 16 hours. Discharged, the polymer product was purified by precipitation with 200ml of cold water, and dried for later use.

[0040] (2) Polymer crosslinking. Pour 10ml of acetone solution containing 0.1880g of polymer into a 25ml single-neck bottle with a magnetic stirrer, add 2ml of aqueous solution containing 0.0160g of ferrous sulfate heptahydrate under stirring, mix well and cast the sol directly on the glass mold In the process, the solvent is evaporated by vacuuming, and a cross-linked metal supramolecular ...

Embodiment 3

[0043] (1) RAFT aggregation. A mixed monomer of 15.56g lauryl acrylate and 7.78g methyl methacrylate and 3.89g methacrylate-12-(2,2':6',2"-terpyridine-4'-oxyl) lauryl After dissolving the monomer with 8.00ml of ethyl acetate, add it to a 50ml reactor, start stirring, blow nitrogen to drive oxygen for 10 minutes, then add 0.1276g of dithiobenzoic acid-2-(ethoxycarbonyl) isopropyl ester and 0.0360 2.00ml ethyl acetate solution of g dicyclohexyl peroxydicarbonate.Reacted in an oil bath at 50°C for 12 hours.Discharging, the polymer product was precipitated and purified with 275ml of cold water, dried for subsequent use.

[0044] (2) Polymer crosslinking. Pour 10ml of tetrahydrofuran solution containing 0.1548g of polymer into a 25ml single-neck bottle with a magnetic stirrer, add 2ml of aqueous solution containing 0.0093g of anhydrous cobalt chloride under stirring, mix well and cast the sol directly on a glass mold In the process, the solvent is evaporated by vacuuming, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com