Weaning meat rabbit feedstuff for mouth-open period as well as production process and application thereof

A technology for the production of meat rabbits and young rabbits, which is applied in the fields of application, molding or processing of animal feed, animal feed, etc. It can solve the problems of lack of feed for young rabbits, unscientific processing technology, and unreasonable nutritional mix to achieve palatability Good resistance, high hardness, and the effect of reducing feed waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

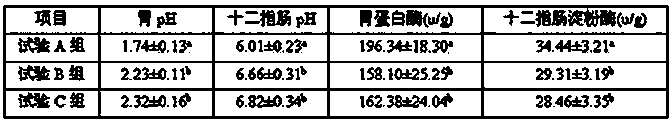

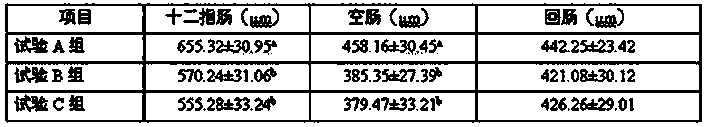

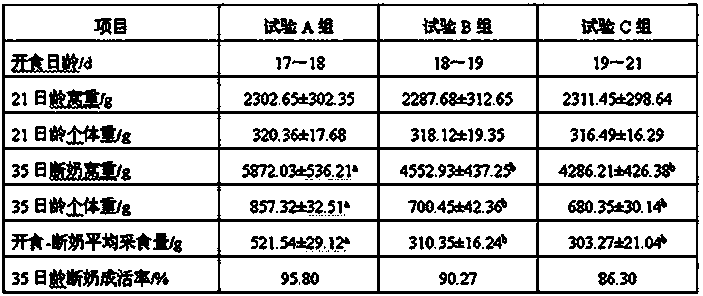

Examples

Embodiment 1

[0022] 24 parts of alfalfa powder, 14 parts of puffed corn, 8 parts of whey powder, 1.5 parts of fish meal, 4.25 parts of fermented soybean meal, 4 parts of puffed soybean, 18 parts of wheat bran, 5 parts of plasma protein powder, 4 parts of white sugar, 14 parts of flour, 0.5 part of calcium hydrogen phosphate, 0.6 part of calcium formate, 0.4 part of table salt, 0.3 part of lysine, 0.2 part of methionine, 0.1 part of glutamine, 0.15 part of tryptophan, 1 part of additive, the sum of the percentage content of each component is 100 copies. Alfalfa powder is the national standard grade 1 alfalfa powder.

[0023] The additive is composed of ferrous fumarate, zinc lactate, copper citrate, manganese citrate, chlorhexidine, compound enzyme, vitamin A acetate, vitamin E acetate, vitamin K 3 , folic acid, biotin, nicotinic acid, vitamin C, choline chloride and bentonite, based on 1000 parts by weight of the premix, wherein the weight part of ferrous fumarate is 100 parts, zinc lacta...

Embodiment 2

[0033] 32 parts of alfalfa powder, 20 parts of puffed corn, 4 parts of whey powder, 0.5 parts of fish meal, 3.5 parts of fermented soybean meal, 2 parts of puffed soybean, 12 parts of wheat bran, 3 parts of plasma protein powder, 3 parts of white sugar, 16.65 parts of flour, 0.8 part of calcium hydrogen phosphate, 0.4 part of calcium formate, 0.6 part of table salt, 0.1 part of lysine, 0.1 part of methionine, 0.3 part of glutamine, 0.05 part of tryptophan, 1 part of additive, the sum of the percentage content of each component is 100 copies.

[0034] The specific operation steps of the production process are as follows:

[0035] The step-by-step mixing method is adopted, the raw materials of the components greater than 5 parts are added to the batching bin through the large silo, and the components of less than 5 parts are manually mixed and then added to the batching bin through the small feed port, and then crushed and mixed by using the process of mixing first and then powd...

Embodiment 3

[0040] The percentage content of each component in the open feed formula is: 26 parts of alfalfa powder, 16 parts of puffed corn, 7 parts of whey powder, 0.8 part of fish meal, 4.3 parts of fermented soybean meal, 3.5 parts of puffed soybean, 16 parts of wheat bran, 3.5 parts of plasma protein powder, 3 parts of white sugar, 16.48 parts of flour, 0.8 parts of calcium hydrogen phosphate, 0.55 parts of calcium formate, 0.45 parts of table salt, 0.2 parts of lysine, 0.15 parts of methionine, 0.15 parts of glutamine, 0.12 parts of tryptophan , 1 part of additive, the sum of the percentage content of each component is 100 parts.

[0041] The specific operation steps of the production process are as follows:

[0042] The step-by-step mixing method is adopted, the raw materials of the components greater than 5 parts are added to the batching bin through the large silo, and the components of less than 5 parts are manually mixed and then added to the batching bin through the small feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com