Relaxation ferroelectric monocrystal pyroelectric infrared detector and preparation method thereof

A relaxor ferroelectric single crystal and pyroelectric infrared technology, applied in the infrared field, can solve problems such as difficult implementation and fixed area, and achieve the effects of effective control, high Curie temperature, and high detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

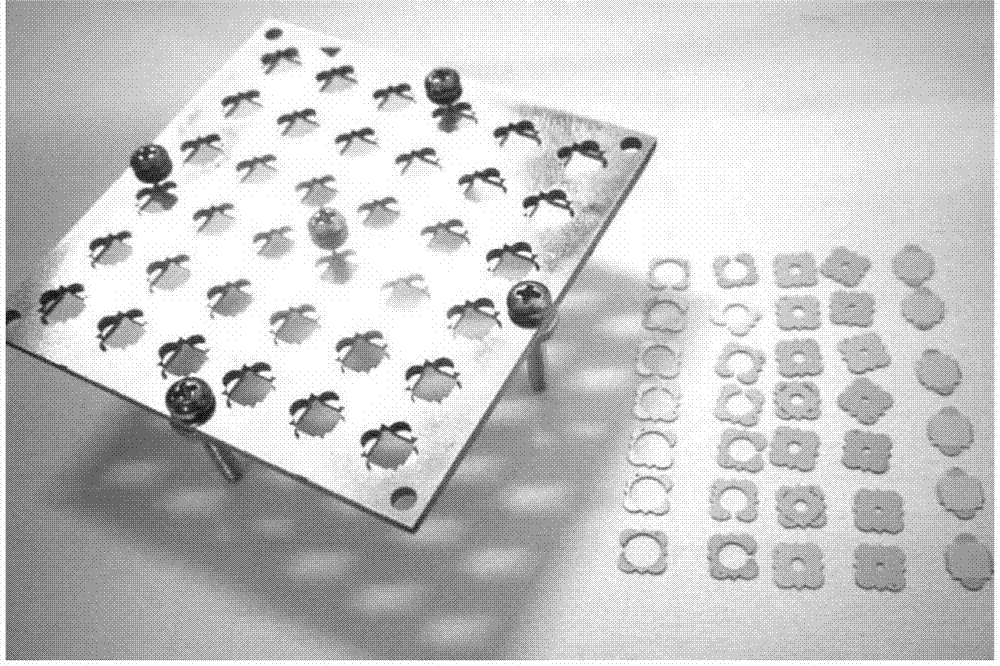

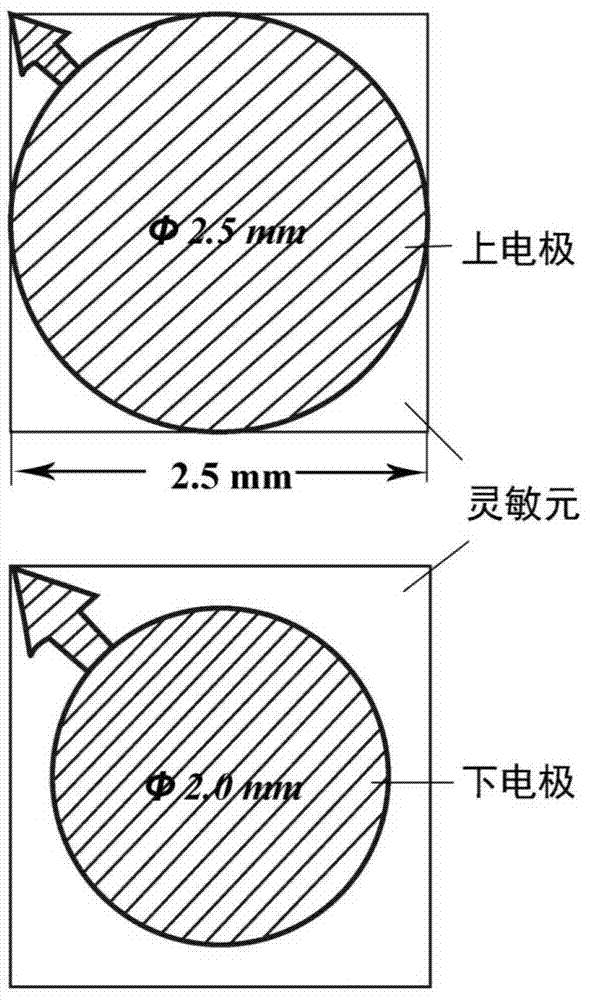

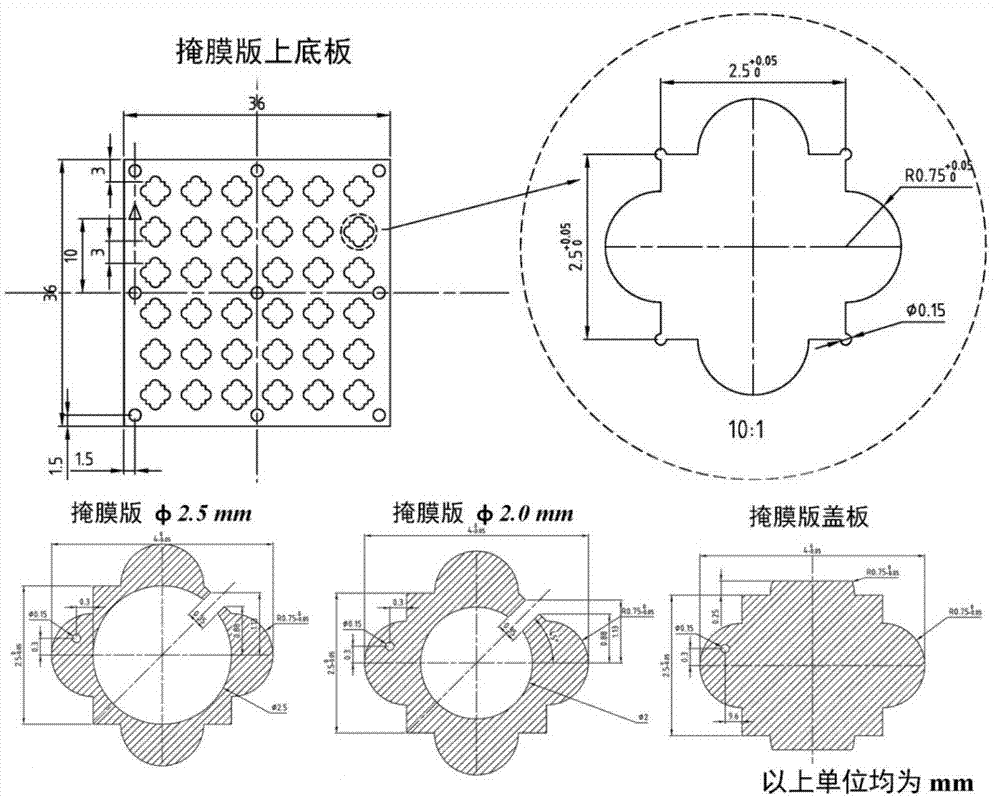

[0058] The method of Patent Document 1 (improved Bridgman method) was used to grow a large-size and high-performance relaxor ferroelectric single crystal, that is, a Mn-doped PMNT single crystal, and then the single crystal was oriented, cut, post-treated, and tested for performance. A series of technological processes select single crystals with excellent performance for further processing. Using chemical mechanical thinning and polishing, the large size 20×20mm 2 The wafer is thinned and polished to 20μm, and then the extremely thin single crystal is diced into 2.5×2.5mm using a dicing machine 2 To prepare the sensitive element of the pyroelectric infrared detector.

[0059] After the single crystal is diced, magnetron sputtering is used to sputter and deposit, for example, Ni-Cr electrodes and Ni-Cr / Au electrodes on its upper and lower surfaces as upper and lower electrodes. The electrode size can be divided into φ2.5mm and φ2. There are four types of .0mm, φ1.0mm and φ0.5mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com