Process for preparing toluene diisocyanate (TDI) by using toluenediamine and dimethyl carbonate

A technology of toluene diisocyanate and dimethyl carbonate is applied in the technical field of preparing toluene diisocyanate by using toluene diamine and dimethyl carbonate, which can solve the problem that there is no two-stage series operation decomposition reactor decomposer process introduction, no consideration The comprehensive and rational utilization of catalysts, the increase of equipment costs and production costs, etc., achieve the effects of good catalytic effect, saving operation steps and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

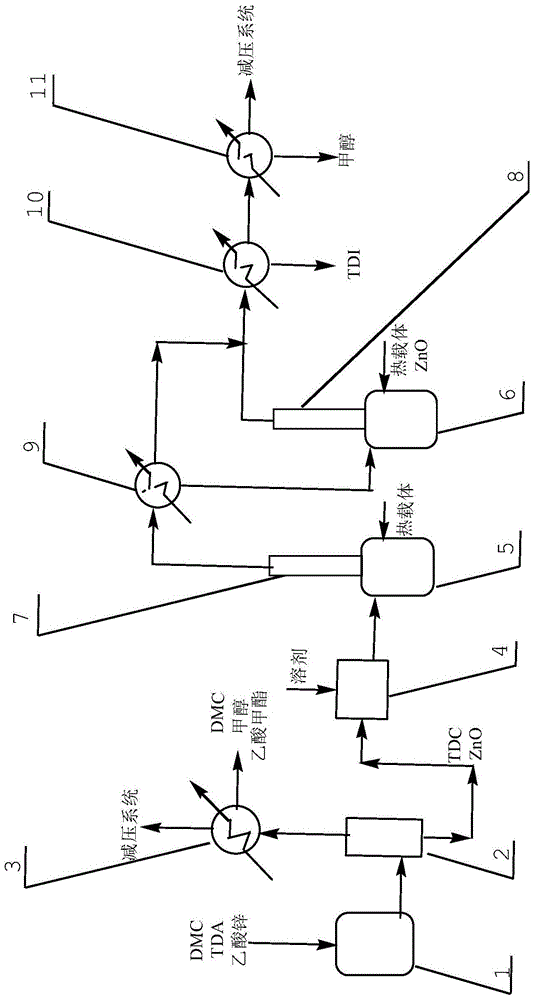

[0044] (1) Add 5g of 2,4-toluenediamine, 97mL of dimethyl carbonate, and 0.82g of zinc acetate to reaction kettle 1 in sequence, and then seal the reaction kettle. Under stirring conditions, heat to 140°C and react for 3 hours; then raise the temperature to 170°C, and maintain the reaction for 3 hours from the start of the temperature rise, and the reaction ends. After the reaction is completed, the feed liquid is cooled and discharged, and the vacuum distillation kettle 2 is cooled at 30°C and 5kP a Under reduced pressure distillation, 10.1 g of a solid product, a mixture of methyl toluene dicarbamate and zinc oxide, was obtained. The product was analyzed by high performance liquid chromatography, and the yield of methyl toluene dicarbamate was 99.2%.

[0045] The gaseous phase that decompression distills out goes to condenser 3, obtains the liquid mixture of dimethyl carbonate, methyl alcohol and methyl acetate after condensation, separates dimethyl carbonate by conventional...

Embodiment 2

[0049] Step (1) is the same as in Example 1.

[0050] (2) Add 50mL of dibutyl phthalate to the two-stage decomposition reactors 5 and 6 respectively, and at the same time pass nitrogen, add 0.2g zinc oxide (the TDC obtained in the previous step and ZnO) to the second-stage decomposition reactor 6 mixture, ZnO was obtained after separation). Adjust the pressure of the reaction system to 10kPa, adjust the temperature of the cooling medium in the subcondenser 9 to 15°C, adjust the temperature of the cooling medium in the subcondenser 10 to 20°C, and adjust the temperature of the cooling medium in the condenser 11 to 0°C. The first-stage decomposition reaction The temperature of the reactor is 220°C, and the temperature of the second-stage decomposition reactor is 240°C. Dissolve 1.4g of the mixture of TDC and zinc oxide obtained in step (1) into an appropriate amount of dibutyl phthalate, and add it to the first-stage decomposition reactor at a uniform speed. The reaction time o...

Embodiment 3

[0052] (1) Add 5g of 2,6-toluenediamine, 104mL of dimethyl carbonate, and 0.38g of zinc acetate to reactor 1 in sequence, and then seal the reactor. Under stirring conditions, heat to 120°C and react for 1 hour; then raise the temperature to 180°C, and maintain the reaction for 2 hours from the start of the temperature rise, and the reaction ends. Cooling and discharging, the feed liquid was distilled under reduced pressure at 40°C and 15kPa to obtain a solid product of 9.71g of a mixture of methyl toluene-2,4-dicarbamate and zinc oxide, and the product was analyzed by high performance liquid chromatography. The yield of methyl toluene dicarbamate is 95.0%.

[0053] (2) Add 50mL of naphthenic oil to the two-stage decomposition reactors 5 and 6 respectively, and at the same time pass nitrogen, add 2g of zinc oxide (the mixture of TDC and ZnO obtained in the previous step, obtained after separation) into the second-stage decomposition reactor ZnO). Adjust the pressure of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com