Catalyst for preparing formaldehyde by methanol oxidation

A catalyst, oxidation technology, applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, carbon-based compound preparation, etc., can solve the problems of high reaction temperature and low yield of target product, etc. To achieve the effect of lowering the reaction temperature, reducing the loss and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method comprises the following steps:

[0021] a) Provide a mixed material containing water-soluble molybdenum salt and soluble vanadium salt

[0022] It should be noted that molybdenum in the catalyst of the present invention can be molybdenum in any oxide form, such as molybdenum oxide or molybdate. More preferred are water soluble molybdenum salts, most preferably the starting material is ammonium molybdate.

[0023] In addition, the vanadium element in the catalyst can be introduced by a similar method, and the preferred starting material is ammonium metavanadate.

[0024] In order to improve the strength of the catalyst, according to some embodiments of the present invention, the step a) includes:

[0025] a-1) preparing the water-soluble molybdenum salt and the soluble vanadium salt into a mixed solution;

[0026] a-2) adding silica sol into the mixed solution to obtain the mixed material.

[0027] Wherein, when the catalyst is used in a fluidi...

Embodiment 1

[0061] 814.6g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to hot water at 70°C, stirred to dissolve it completely, and 29.8g NH 4 VO 3 , to make material A.

[0062] Add 2500.1g 40% (wt) silica sol to material A to make material B.

[0063] 462.7gNi(NO 3 ) 2 ·6H 2 O was added to hot water at 70°C and stirred to dissolve it completely. After adding 321.4g Fe (NO 3 ) 3 9H 2 O, 169.8gBi (NO 3 ) 3 ·5H 2 O, 124.6gPr(NO 3 ) 3 ·6H 2 After O is stirred and dissolved, material C is made.

[0064] Add material C dropwise to material B under rapid stirring, and after aging for 4 hours at a constant temperature of 80°C, use an atomizing disc with a diameter of 60mm to spray dry it at a speed of 12,000 rpm at 150°C. The catalyst was placed in a rotary roaster, and activated by roasting at 670° C. for 2.5 hours to obtain a finished catalyst.

[0065] The composition of catalyst active components is shown in Table 2, and the evaluation results are shown in Table 3.

Embodiment 2~7

[0067] Except that the starting materials are added according to Table 1, the preparation method is the same as that of Example 1.

[0068] The composition of the catalyst active components is shown in Table 2. The evaluation results are shown in Table 3.

[0069] Table 1 Starting materials and corresponding dosage (unit: g)

[0070]

[0071] Table 2 Catalyst active component composition table

[0072]

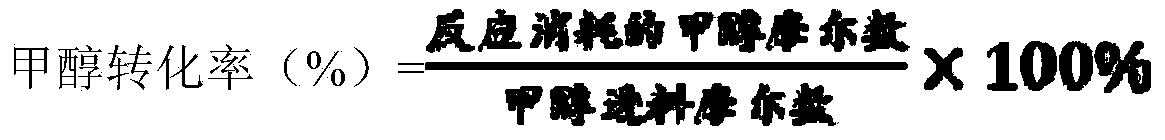

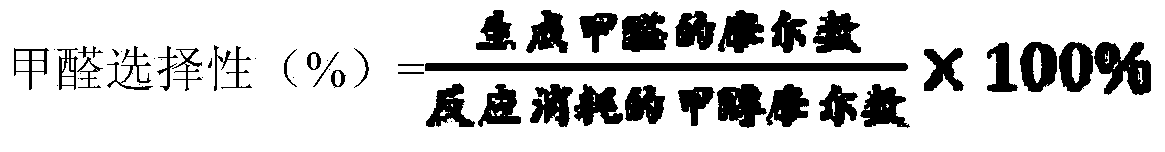

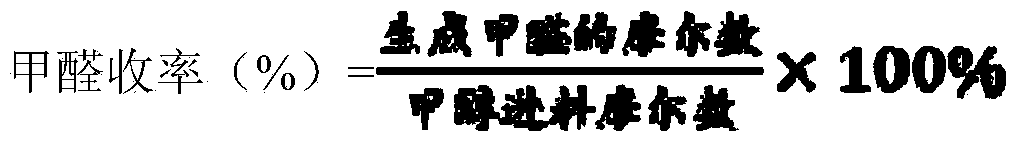

[0073] Table 3 Catalyst Activity Evaluation Results

[0074]

[0075] Table 3 is the evaluation result of catalyst activity, as can be seen from the table, the embodiment that the present invention obtains is on methanol conversion rate, formaldehyde selectivity, formaldehyde yield, all compares comparative example (methanol oxidation production formaldehyde iron molybdenum used in industry) Catalyst) test results have been significantly improved, showing better results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com