Solar cell, its module and its manufacturing method

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of damaged back electric field structure function, poor current collection efficiency, and poor battery conversion efficiency, etc., to achieve Improve the current collection effect, increase the open circuit voltage, and eliminate the effect of the terminal part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

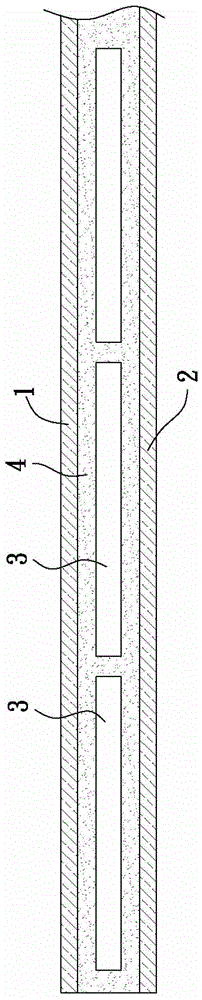

[0042] refer to image 3 , Figure 4 The first preferred embodiment of the solar cell module of the present invention includes: a first plate 1 and a second plate 2 oppositely arranged, and a plurality of arrays arranged between the first plate 1 and the second plate 2 Solar cells 3 , and at least one packaging material 4 located between the first plate 1 and the second plate 2 and in contact with the plurality of solar cells 3 . Wherein, the module can include at least one solar cell 3 , and multiple solar cells 3 are not absolutely necessary.

[0043] The implementation of the first plate 1 and the second plate 2 is not particularly limited, glass or plastic plates can be used, and the plate on the side of the light-receiving surface of the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com