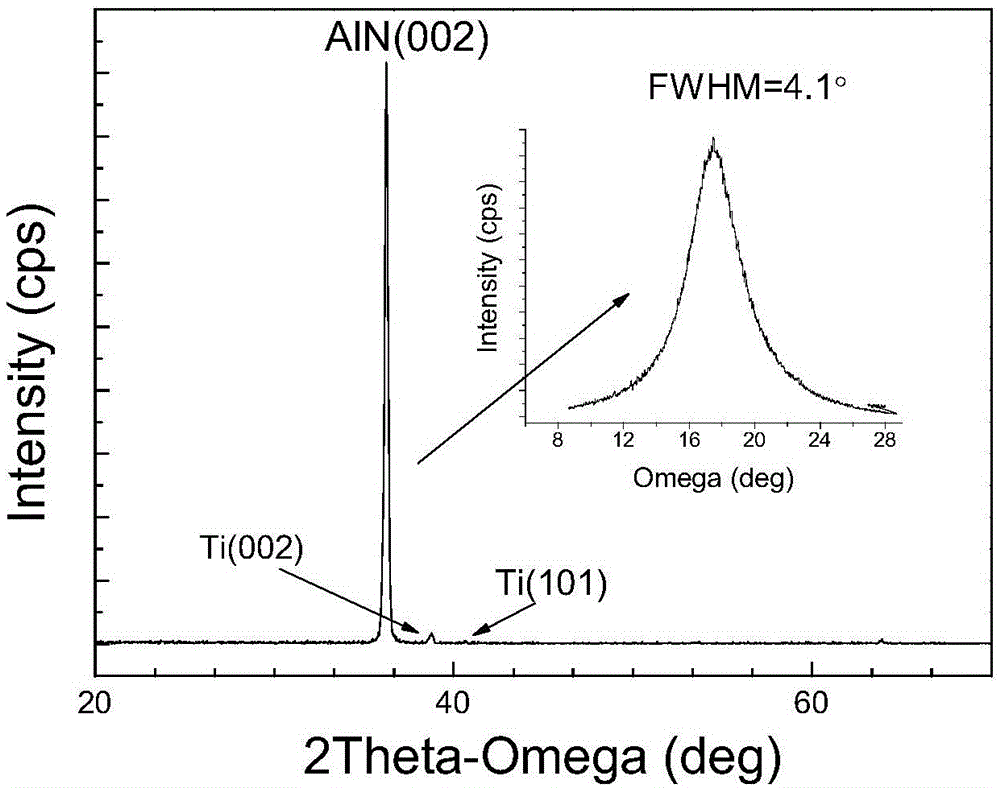

A method for preparing c-axis oriented aluminum nitride film on the surface of titanium alloy substrate

A technology of titanium alloy and aluminum nitride, applied in the field of thin film material preparation, can solve the problems of low surface roughness, low reliability and short life, and achieve the effect of good piezoelectric effect and low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] A method for preparing a C-axis orientation aluminum nitride film on the surface of a titanium alloy substrate, comprising the following steps:

[0024] a. First, clean the TC4 titanium alloy substrate roughly polished by polishing paste with ultrasonic waves, then use acetone, alcohol, and deionized water to clean the substrate in turn, and blow it dry with nitrogen gas. Put the cleaned substrate into a drying oven filled with pure nitrogen gas. Heat to 120°C in a dry box and dry for 1 hour to remove moisture on the surface of the substrate. Prevent stains and moisture from affecting the quality of the grown film.

[0025] b. Place the cleaned and dried substrate on the substrate stage of the intermediate frequency magnetron sputtering apparatus with a clamp, and then close the cavity. Start the magnetron sputtering instrument normally, and evacuate the cavity to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com