Welded type glass red wine stemware and welding process thereof

A glass and welding technology, applied in glass molding, glass re-molding, glass manufacturing equipment and other directions, can solve the problems of insufficient shape, high cost, high energy consumption, etc., and achieve beautiful appearance, thick base, and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A welded goblet wine glass, comprising a cup body and a base, the base and the cup body are welded together by ultrasonic welding;

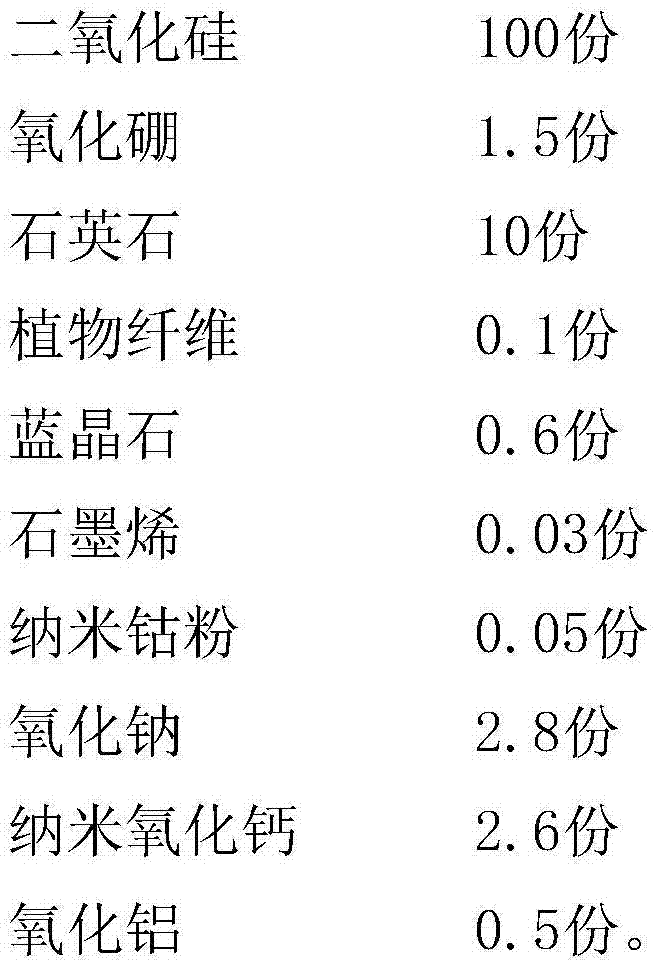

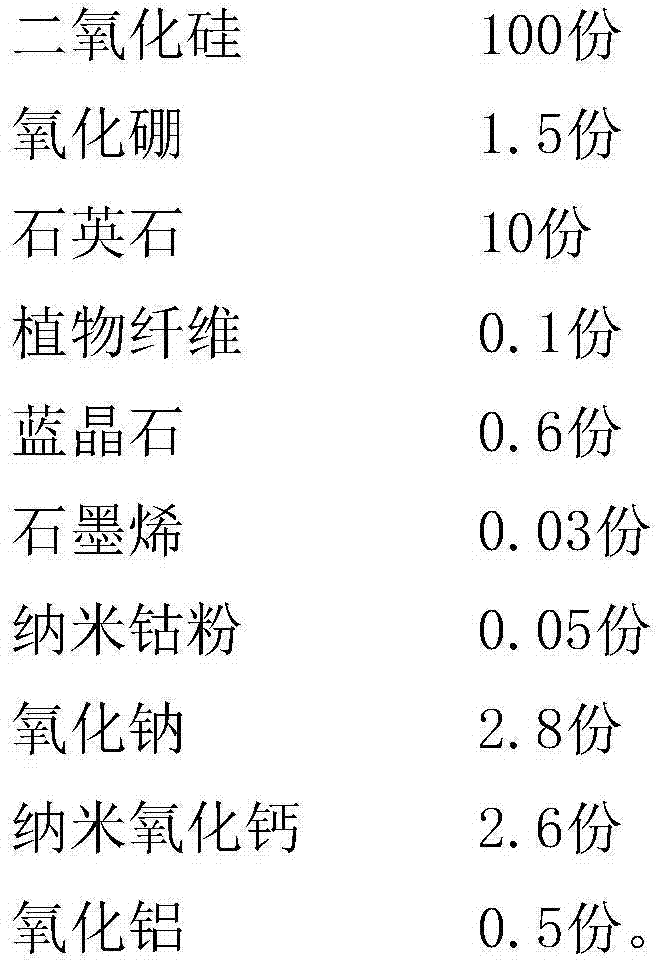

[0023] Both the base and the cup body are composed of the following components by weight,

[0024]

[0025] Another object of the present invention is to provide a welding process for a tall wine glass, comprising the following process steps:

[0026] 1) According to the size and shape requirements of the prepared glass, the above components are melted and blown into a glass body;

[0027] 2) According to the size and shape requirements of the cup body, melt the above components to prepare a base with a suitable size that matches the cup body;

[0028] 3) The base is formed by a mold, and after forming, it is placed in an incubator at 40°C for 24 hours to keep warm for 24 hours. The heat preservation treatment can prevent the base from bursting during welding;

[0029] 4) Slowly raise the temperature of the heat-preserved base to 300°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com