Welded single-layer crystal glass and its welding process

A glass and welding technology, which is applied in glass molding, glass reshaping, glass manufacturing equipment, etc., can solve the problems of insufficient shape, high cost, and long time, and achieve beautiful appearance, good hardness, and short time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A welded single-layer crystal glass, including a cup bottom and a cup body, the cup bottom and cup body are welded together by ultrasonic welding;

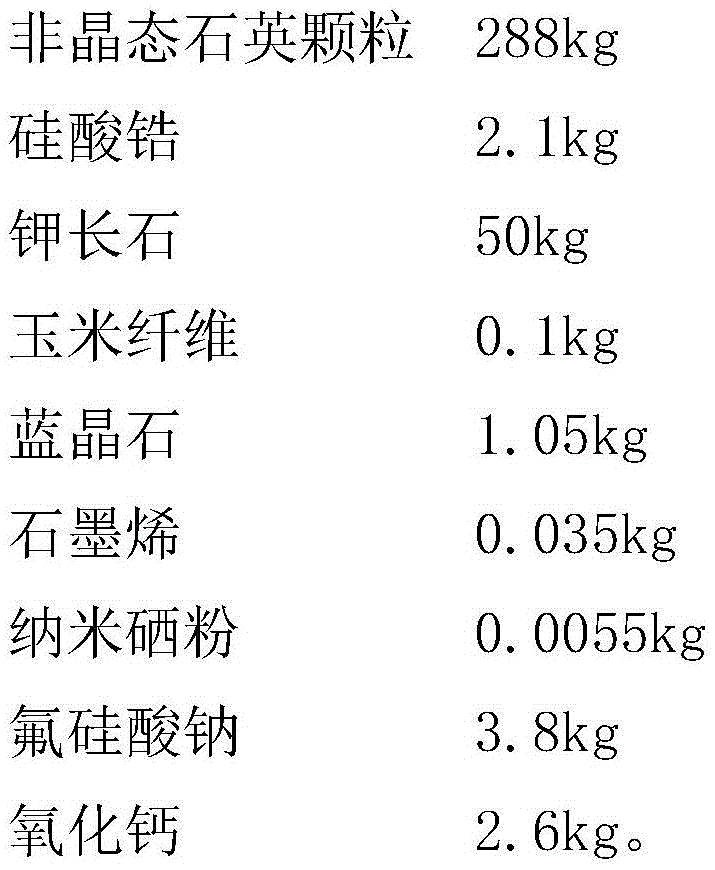

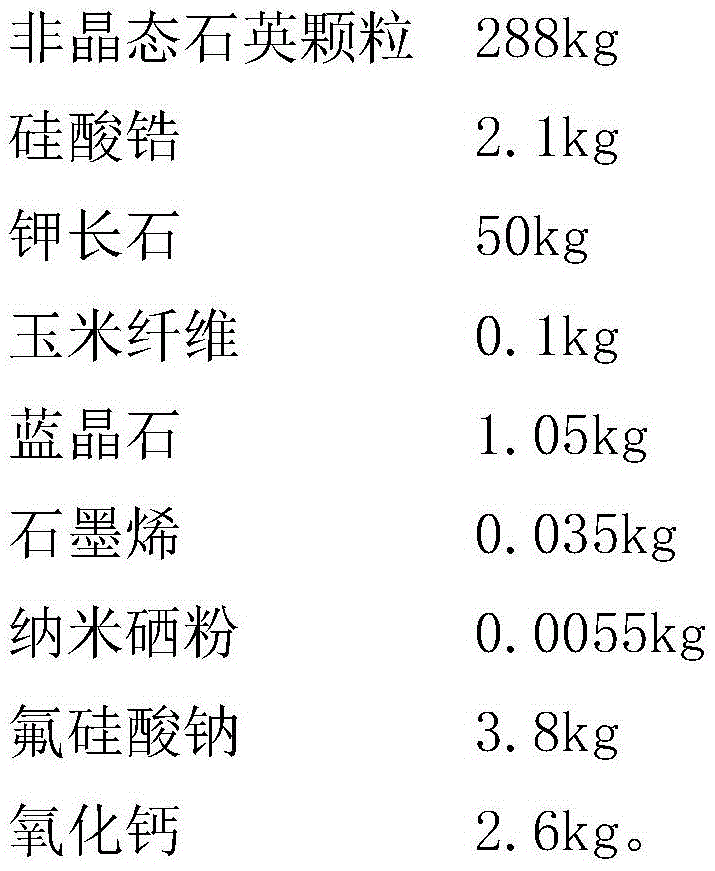

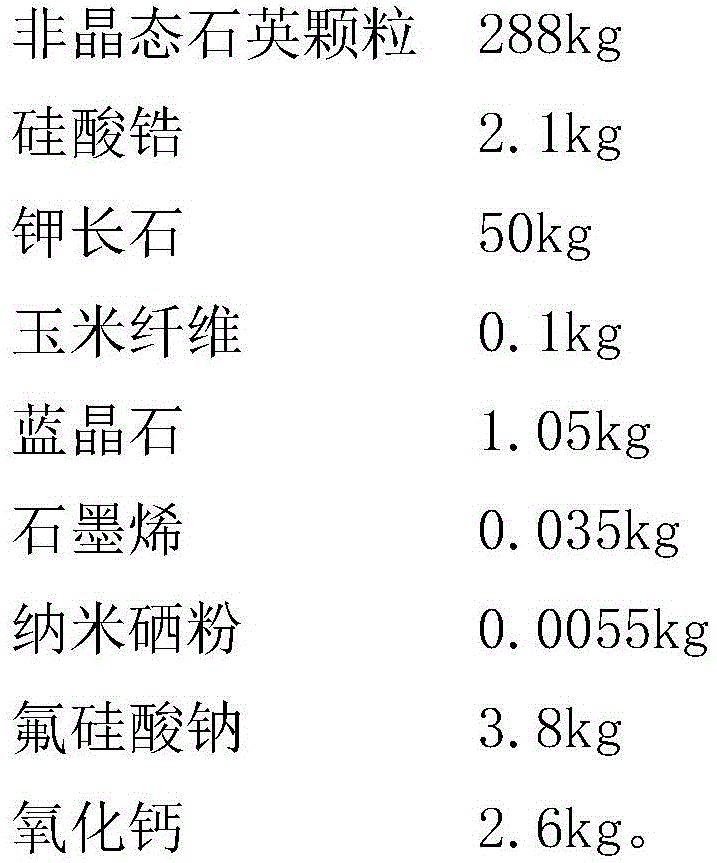

[0023] Both the bottom of the cup and the body of the cup are composed of components with the following weights,

[0024]

[0025] Another object of the present invention is to provide a welding process for a single-layer crystal glass, comprising the following process steps:

[0026] 1) According to the size and shape requirements of the prepared glass, the above components are melted and blown into a glass body, which is generally cylindrical;

[0027] 2) According to the size and shape requirements of the cup body, melt the above components to prepare a cup bottom with a suitable size and matching with the cup body;

[0028] 3) The bottom of the cup is formed by a mold. After forming, it is placed in an incubator and kept at 40°C for 24 hours. Through the heat preservation treatment, the bottom of the cup can be crac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com