Preparation method of tungsten and cobalt solder for cathodes and brazing component manufacturing method and application thereof

A technology of solder and tungsten-cobalt, which is applied in the field of preparation of brazing components, can solve problems such as uneven welding gap size, poor solder adhesion, and weld sand holes, so as to prevent the precipitation of cathode active materials, reduce particle size, and improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a kind of preparation method for the tungsten-cobalt solder of cathode, wherein, this method comprises:

[0029] (1) Reducing tungsten powder and cobalt powder;

[0030] (2) Grinding the mixture of reduced tungsten powder and cobalt powder to obtain tungsten-cobalt solder;

[0031] Wherein, the weight ratio of the tungsten powder to the cobalt powder is 1:2-5.

[0032] In the present invention, in order to more effectively prevent the precipitation of the cathode active material during welding, the weight ratio of the tungsten powder to the cobalt powder is preferably 1:2.5-4.5; more preferably 1:3-4 .

[0033] In the present invention, in order to make the reduction reaction of tungsten powder and cobalt powder more thorough, so that the purity of the obtained tungsten powder and cobalt powder is higher, in step (1), the method of reducing tungsten powder and cobalt powder can be It is method A or method B below.

[0034] Method A: he...

preparation example 1

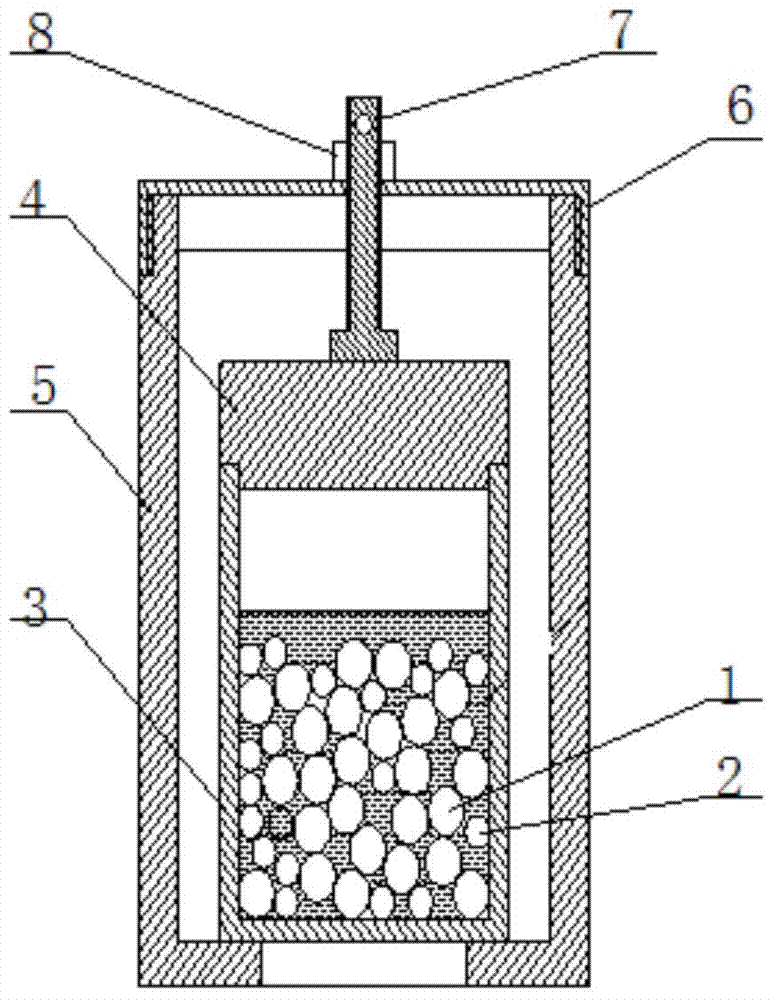

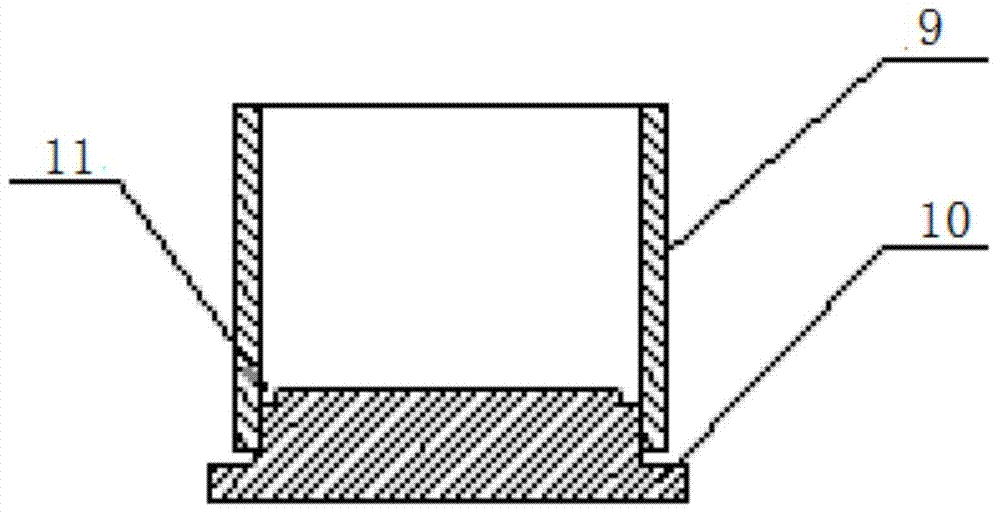

[0059] Spread the tungsten powder and cobalt powder in the molybdenum bowl respectively, and account for 1 / 3 of the volume of the molybdenum bowl, transfer the molybdenum bowl containing the tungsten powder and cobalt powder to the molybdenum tube hydrogen furnace through the drying bottle, The tube hydrogen furnace heats up the temperature at a constant rate of 65°C / min for 12 minutes to 780°C, and performs a high-temperature reduction reaction in the molybdenum tube hydrogen furnace for 35 minutes in a dry hydrogen environment; weigh the obtained in the above steps at a ratio of 1:3 Tungsten powder and cobalt powder; After being mixed with the weighed tungsten powder and cobalt powder, be placed in the agate jar 3 that contains 30 agate balls 1 and 40 diameters of 10mm agate balls 2 with a diameter of 10mm; After the agate jar 3 with a mixture of tungsten powder and cobalt powder is covered with the first cover 4, put it into the outer cover 6, tighten the second cover 5, tig...

preparation example 2

[0061] Spread the tungsten powder and cobalt powder in the molybdenum bowl respectively, and account for 1 / 2 of the volume of the molybdenum bowl, transfer the molybdenum bowl containing the tungsten powder and cobalt powder to the molybdenum tube hydrogen furnace through the drying bottle, The tube hydrogen furnace raises the temperature at a constant rate of 88°C / min for 10 minutes to 880°C, and performs a high-temperature reduction reaction in the molybdenum tube hydrogen furnace for 40 minutes in a dry hydrogen environment; weigh the obtained in the above steps at a ratio of 1:3.5 Tungsten powder and cobalt powder; After being mixed with the weighed tungsten powder and cobalt powder, be placed in the agate jar 3 that contains 30 agate balls 1 and 40 diameters of 10mm agate balls 2 with a diameter of 10mm; After the agate jar 3 with a mixture of tungsten powder and cobalt powder is covered with the first cover 4, put it into the outer cover 6, tighten the second cover 5, tig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com