A kind of elastic gel scaffold material for bone tissue engineering and its preparation method

A technology of bone tissue engineering and elastic gel, applied in the field of elastic gel scaffold materials, can solve the problems of loss of mechanical properties, easy dissolution, use of tissue engineering materials, etc., and achieve excellent biological functions and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

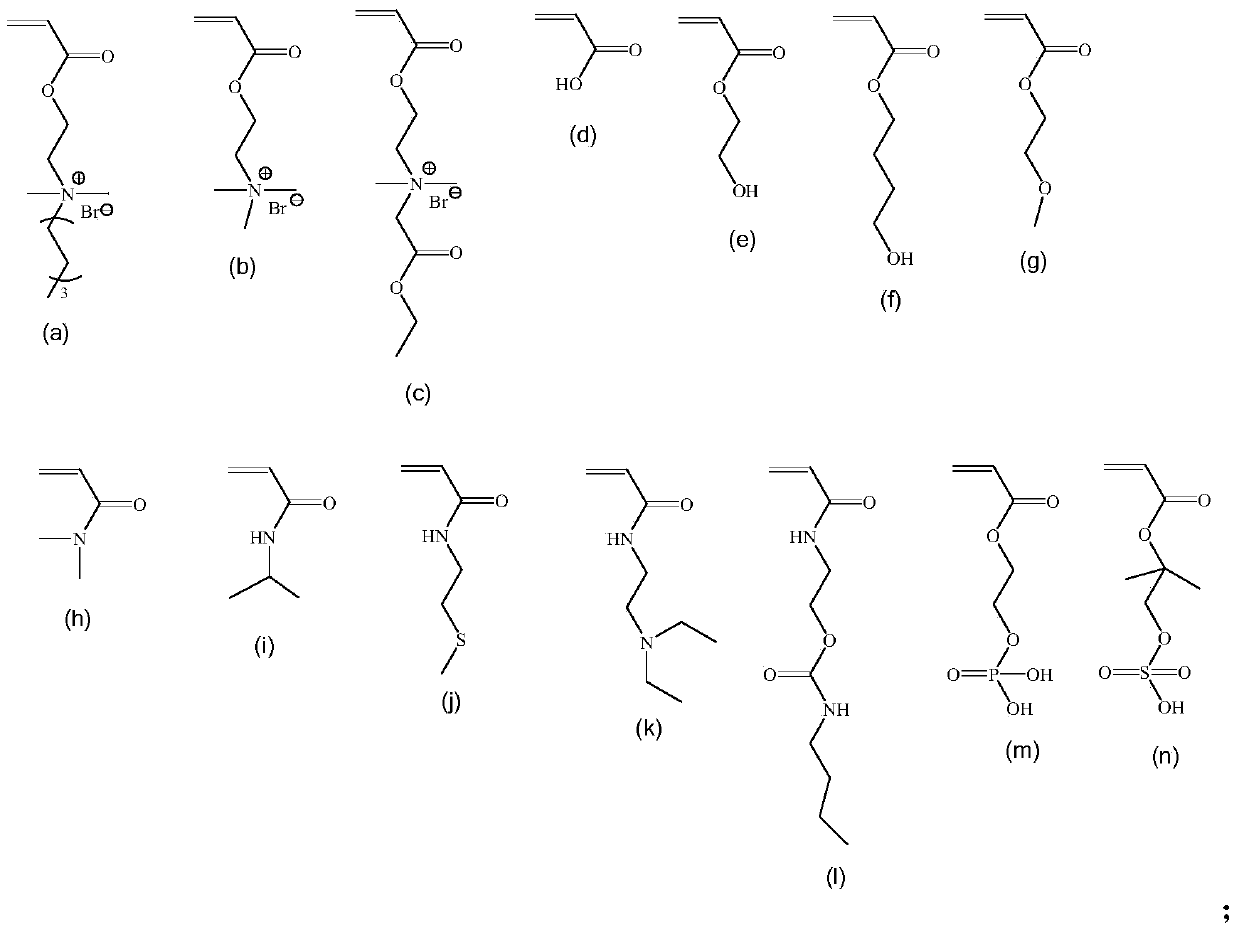

Embodiment 1

[0048] Step (1). Add 1.09 g of gel N1 reactive monomer (c), 0.54 g of gel N1 reactive monomer (h), and 0.024 g of N,N-methylenebisacrylamide cross-linked monomer into a 15 ml plastic tube. The joint agent and tetramethylethylenediamine accelerator were dissolved in 6.5 ml of deionized water, and nitrogen gas was introduced for 30 minutes to remove the oxygen in the system, and then 300 microliters of ammonium persulfate solution (1% in mass) was added with a syringe, Shake well and react at 25°C for 12 hours to obtain gel N1.

[0049] Step (2). Take the gel N1 out of the plastic tube and cut it into 1-3 cm columnar gel blocks with a knife. Prepare a 200 mL gel N2 reaction solution of acrylamide (28.4 g), α-ketoglutarate (0.58 g), and N,N-methylenebisacrylamide (0.062 g). Put the gel block of gel N1 into the gel N2 reaction solution, seal it with aluminum foil, and shake slightly for 48 hours. Then, take out the gel block that has been fully soaked, and put it under ultraviol...

Embodiment 2

[0052] Step (1). Add 1.09 g of gel N1 reactive monomer (c), 0.54 g of gel N1 reactive monomer (h), and 0.024 g of N,N-methylenebisacrylamide cross-linked monomer (c) into a 15 ml plastic tube. The joint agent and tetramethylethylenediamine accelerator were dissolved in 6.5 ml of deionized water, and nitrogen gas was introduced for 30 minutes to remove the oxygen in the system, and then 300 microliters of ammonium persulfate solution (1% in mass) was added with a syringe, Shake well and react at 25°C for 12 hours to obtain gel N1.

[0053] Step (2). Take the gel N1 out of the plastic tube and cut it into 1-3 cm columnar gel blocks with a knife. Prepare a 200 mL gel N2 reaction solution of acrylamide (56.8 g), α-ketoglutarate (1.16 g), and N,N-methylenebisacrylamide (0.124 g). Put the gel block of gel N1 into the gel N2 reaction solution, seal it with aluminum foil, and shake slightly for 48 hours. Then, take out the gel block that has been fully soaked, and put it under the u...

Embodiment 3

[0055] The double network gel obtained in Example 2 was cut into small pieces of 5mm*5mm*2mm, washed three times with deionized water, frozen at -20°C, and dried in vacuum, then soaked in 70% alcohol solution After 2 hours, wash with PBS for 3 times in a sterile environment, and then soak overnight in PBS.

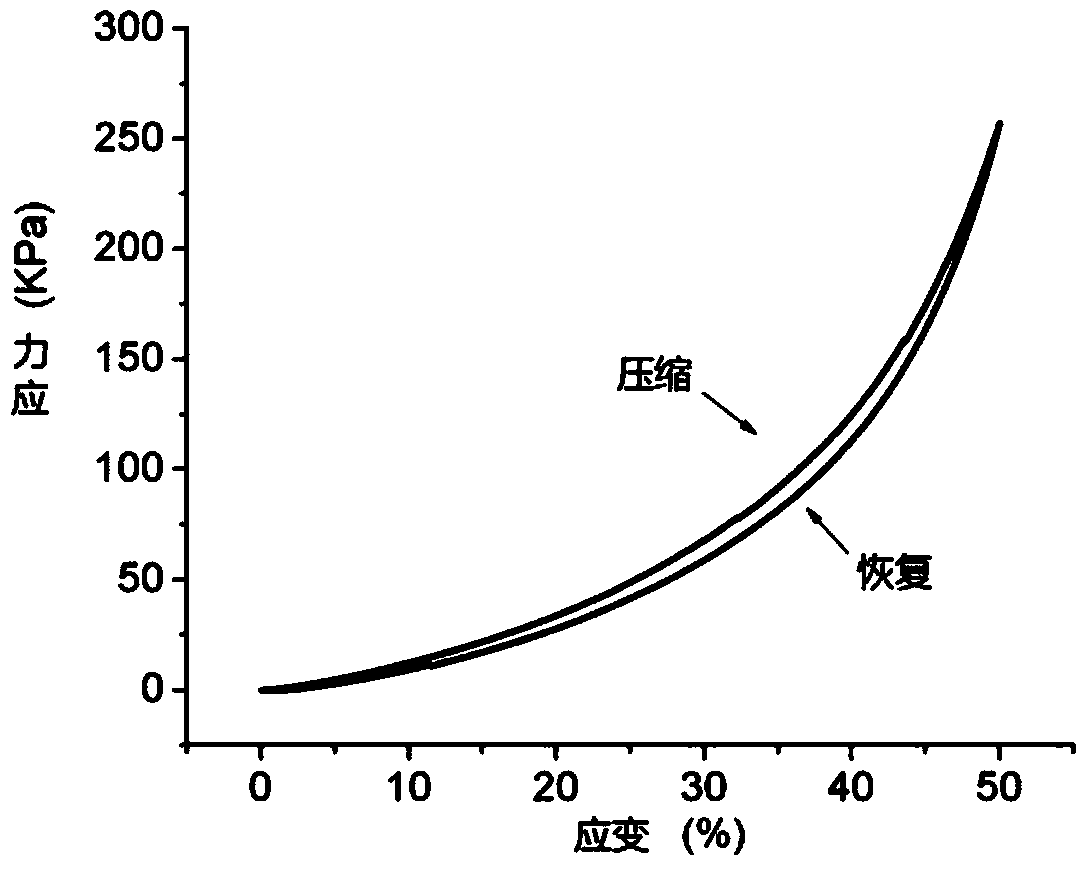

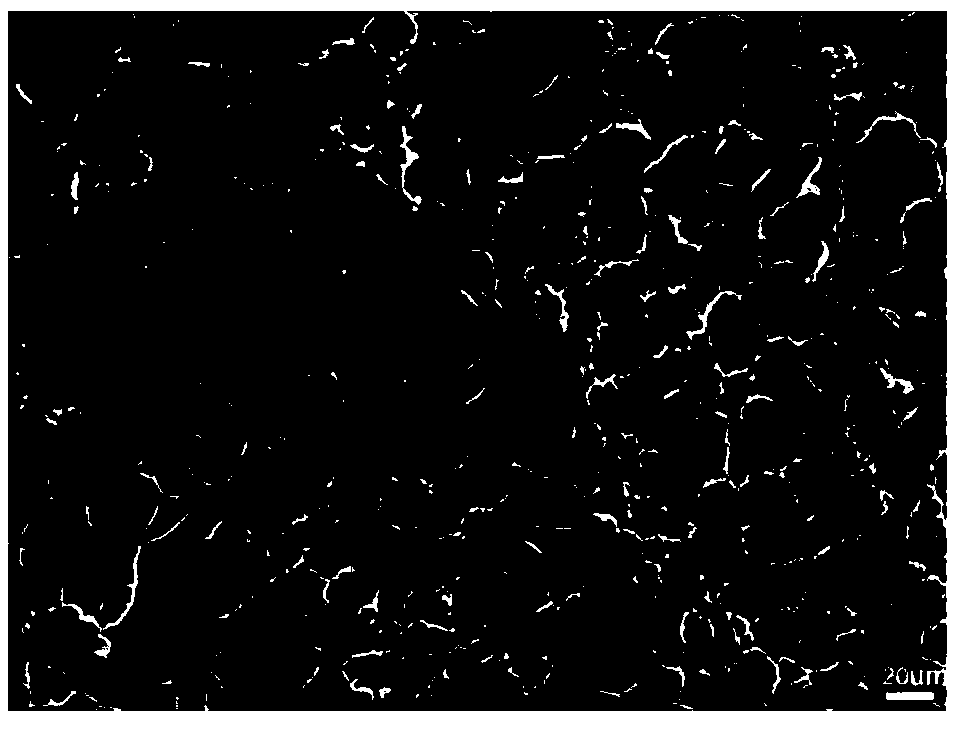

[0056] Adipose-derived mesenchymal stem cells were planted on the double network gel, added with DMEM growth medium containing 10% fetal bovine serum, cultured at 37°C, 5% carbon dioxide environment for 3 days, and stained with DAPI dye. A large number of adipose stem cells adhered and grew on the surface of the gel, which indicated that the gel had excellent biocompatibility. When the fullness increased to about 80%, the osteoinductive medium (StemPro, GIBCO) was used to culture at 37°C and 5% carbon dioxide for 21 days. The double network gel scaffold was stained with alizarin, and the calcified morphology of the gel surface could be observed under a microscope. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com