Photovoltaic micro-inverter power generation system based on multi-winding high-frequency magnetic coupling system

A power generation system, magnetic coupling technology, applied in the direction of photovoltaic power generation, electrical components, output power conversion devices, etc., can solve the problems of large volume, low efficiency, high noise, etc., achieve the effect of small volume, high power generation efficiency, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

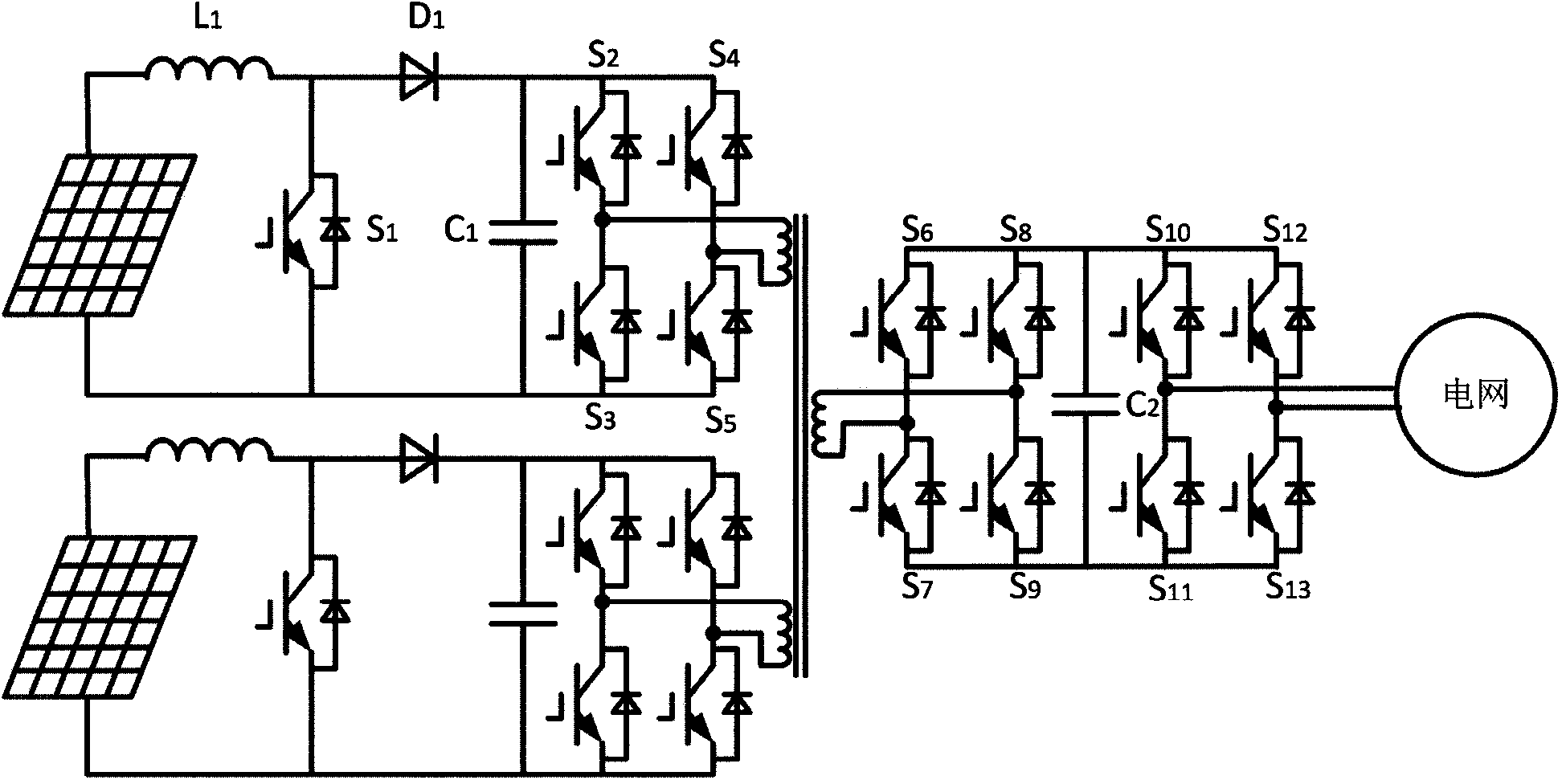

[0033] figure 1 is a schematic topological diagram of a photovoltaic micro-inverter power generation system according to an embodiment of the present invention. Such as figure 1 As shown, the embodiment of the present invention provides a photovoltaic micro-inverter power generation system based on a multi-winding high-frequency magnetic coupling system, which includes a grid-connected system, multiple photovoltaic panels and a control unit. The grid-connected system includes multiple boost topologies, multiple bus capacitors C 1 , multiple H-bridge inverter circuits and a multi-winding transformer and a back-to-back H-bridge inverter circuit. The number of photovoltaic panels, the number of boost topologies, the number of bus capacitors and the number of H-bridge inverter circuits are consistent.

[0034] Specifically, each photovoltaic panel is connected to a boost topology. Each boost topology connects a bus capacitor C 1 . Each bus capacitance C 1 An H-bridge invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com