Method for smelting of ultra-low carbon steel and continuous casting method for ultra-low carbon steel

A technology of ultra-low carbon steel and molten steel, applied in the field of smelting ultra-low carbon steel, can solve the problems of unfavorable mass production of ultra-low carbon steel, restrictions on the production of ultra-low carbon steel and the development of varieties, and low comprehensive pass rate. Reduce the consumption of deoxidizer aluminum, improve the cleanliness of molten steel, and improve the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is used to illustrate the production method of the low carbon steel provided by the present invention.

[0047] The molten iron with a sulfur content of less than 0.015% by weight is initially smelted using a converter. During compound blowing, the top-blown pure oxygen is 28,000 standard cubic meters per hour, and the bottom-blown pure argon has an intensity of 0.035Nm. 3 / ton of molten steel min, blowing argon gas at the bottom for 6 minutes after tapping, and the strength is 0.2Nm 3 / ton of molten steel min, to carry out intensive stirring before tapping; the carbon content at the blowing end point is 0.06% by weight, the oxygen activity content of molten steel is 400ppm, and the temperature of tapping molten steel is 1670°C;

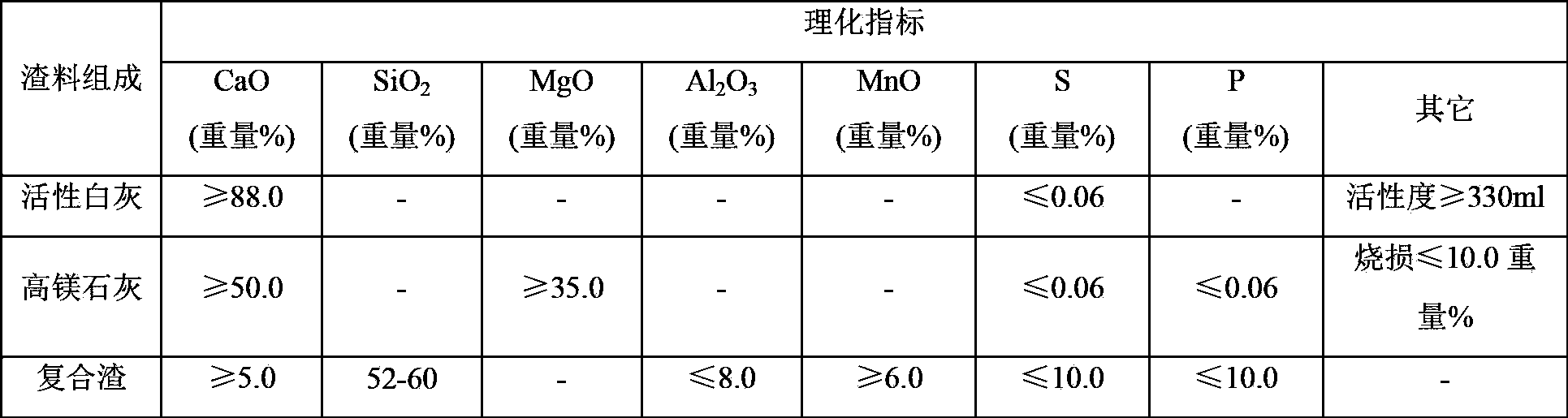

[0048] After the steel converter is smelted, the alkalinity (CaO / SiO 2 The molten steel slag material (refining slag adjusting agent) with a weight ratio) of 4-5 is mixed with molten steel, and the addition amount is 1.5 kg / ...

Embodiment 2

[0061] This embodiment is used to illustrate the production method of the low carbon steel provided by the present invention.

[0062] The molten iron with a sulfur content of less than 0.015% by weight is initially smelted using a converter. During compound blowing, the top-blown pure oxygen is 28,000 standard cubic meters per hour, and the bottom-blown pure argon has an intensity of 0.035Nm. 3 / ton of molten steel min, blowing argon gas at the bottom for 6 minutes after tapping, and the strength is 0.2Nm 3 / ton of molten steel min, to carry out intensive stirring before tapping; the carbon content at the blowing end point is 0.05% by weight, the oxygen activity content of molten steel is 450ppm, and the temperature of tapping molten steel is 1670°C;

[0063] After the steel converter is smelted, the alkalinity (CaO / SiO 2 Weight ratio) of 4-5 slag (molten steel refining slag adjustment agent), mixed with molten steel, the addition amount is 1.5 kg / ton molten steel, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com