Method for utilizing semiconductor membrane to process wastewater

A semiconductor and membrane treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as small area of unit membrane elements, large sealing ring, leakage, etc., to achieve The effect of simple operation, small footprint and high filtration yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

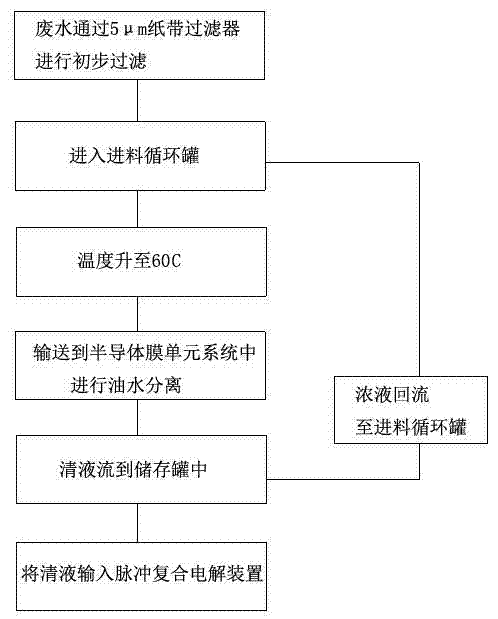

Image

Examples

Embodiment Construction

[0022] The specific implementation method of the present invention will be further described below in conjunction with the examples. This embodiment is used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0023] In a preferred embodiment, a semiconductor membrane unit system made of silicon carbide is used to treat wastewater containing emulsion. The water quality parameters of the wastewater containing the emulsion are as follows:

[0024] COD content: 7960mg / L; PH value: 5.06mg / L; suspended matter content: 402 mg / L; oil content: 644mg / L; cyanide: 0.013 mg / L; ammonia nitrogen: 9.71 mg / L; Kjeldahl nitrogen measurement : 161 mg / L; organic nitrogen: 151 mg / L; sulfide: 0.11 mg / L; sulfate: 146 mg / L; chloride: 2950 mg / L; total phenol content: 2020 mg / L; aluminum ion: 4.09 mg / L; ferrous ion: 30.5 mg / L; molybdenum ion: 10.2 mg / L; phosphorus: 11.0 mg / L; zinc ion: 2.18 mg / L.

[0025] The di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com