Efficient electrodialysis desalinizing device and method for coking wastewater

A coking wastewater and desalination device technology, applied in chemical instruments and methods, separation methods, general water supply saving, etc., can solve the problems of long-term stable operation of the system, low recovery rate of fresh water, large discharge of concentrated water, etc., and achieve the goal of promoting the project The effect of chemical application, high recovery rate of fresh water, and small discharge of concentrated water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

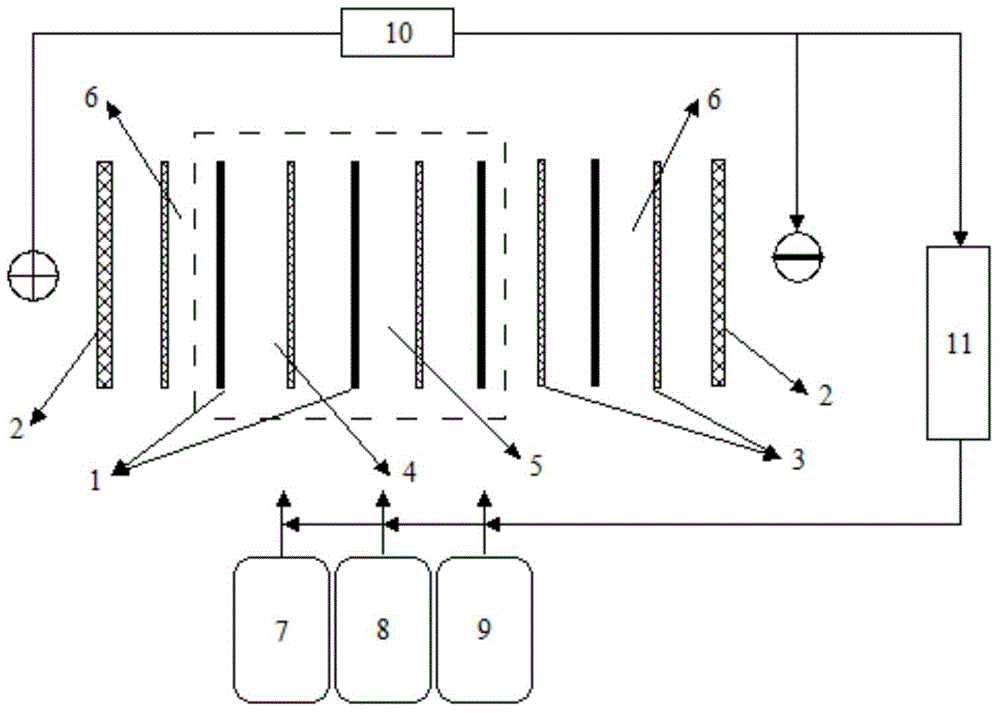

[0037] Example 1 High-efficiency electrodialysis desalination for simulating the treatment of coking wastewater that reaches the standard

[0038] A high-efficiency electrodialysis device was used to desalinate simulated coking wastewater, and the effects of different initial Cl- ions in concentrated water and fresh water on desalination rate, energy consumption and membrane stack voltage were investigated. Studies have shown that when the initial concentration of Cl- in fresh water is 600 mg / L, and the initial concentration of concentrated water is 1200, 5000 and 8000 mg / L, under constant pressure conditions, as the salt content of fresh water decreases, its resistance increases , leading to a drop in current density. After a certain period of treatment, the concentration of Cl- ions in fresh water can be reduced to below 250mg / L. When the concentration gradient of concentrated water and fresh water is large, it will cause ion reverse diffusion; the current efficiency at diff...

Embodiment 2

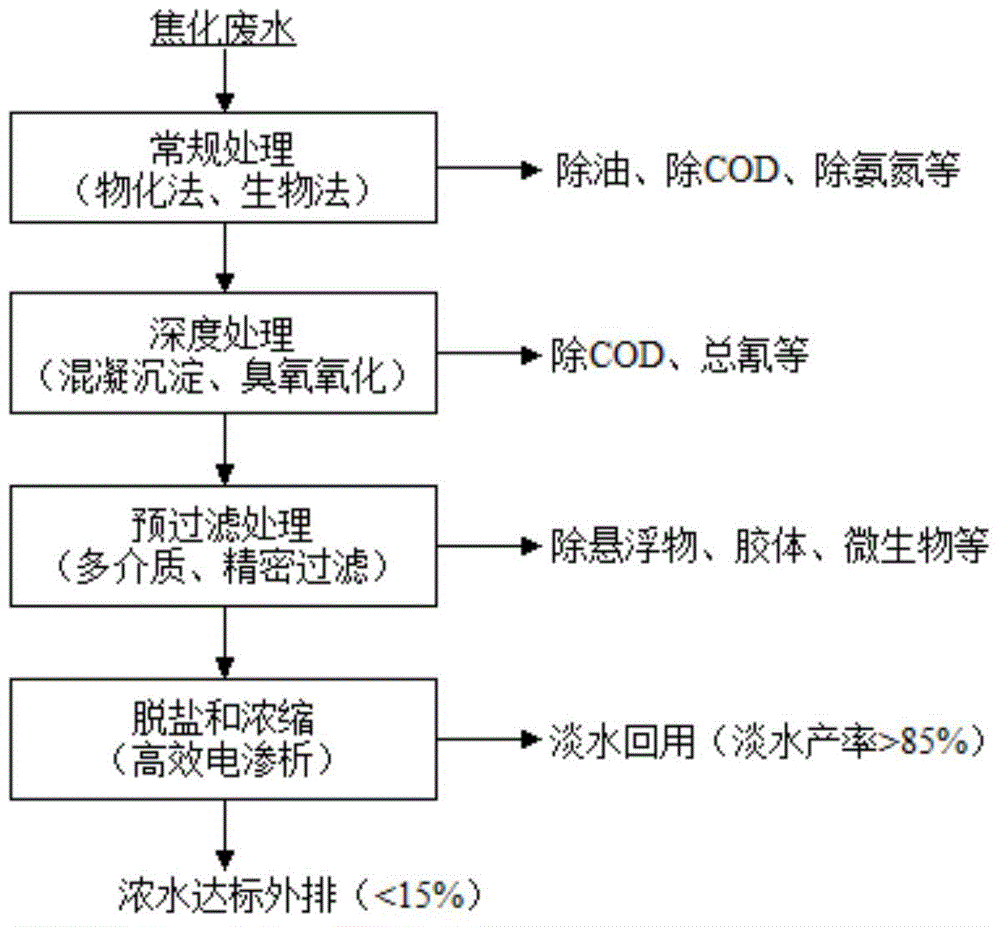

[0039] Example 2 High-efficiency electrodialysis desalination of coking wastewater that reaches the standard

[0040] Although coking wastewater has reached the discharge standard after being treated by conventional physicochemical, biological and membrane technologies, its recycling is limited due to the presence of inorganic salts such as Cl- ions, a small amount of refractory organic matter, suspended particles and bacteria, and further removal of Cl-, etc. Inorganic ions and other pollutants. The waste water that reaches the standard is first filtered with 5μm PP cotton and then enters the electrodialysis system for desalination, using constant potential operation. After 10 batches of continuous desalination experiments, it was found that under the same desalination conditions, the Cl- ion in fresh water dropped to less than 250 mg / L to meet the reuse standard. However, in each batch of experiments, the current density showed a downward trend with the progress of the desa...

Embodiment 3

[0041] Example 3 Pilot-scale study on high-efficiency electrodialysis desalination of coking wastewater discharged to meet the standard

[0042] The high-efficiency electrodialysis device of the present invention is used to carry out pilot-scale research on the desalination of coking waste water that reaches the standard, and a high-efficiency electrodialysis desalination system is constructed. The results show that the device of the present invention is used to treat high-salt wastewater in coal chemical industry, wherein the desalination rate of coking wastewater can be more than 90%, and the Cl-ion content in fresh water is less than 150 mg / L (which can meet the requirements of industrial reuse water standard), the recovery rate of fresh water is above 85%; the concentration ratio of concentrated water is more than 10 times, the discharge of concentrated water is less than 85%, and the COD does not increase, which meets the discharge standard of industrial wastewater and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com