Ultra-high temperature sterilizer and its application

A technology of ultra-high temperature sterilization and sterilization area, which is applied in the direction of heating water/sewage treatment, etc., which can solve the problems of high steam energy consumption, thermal pollution affecting the environment, and high pressure resistance requirements of equipment, so as to achieve low steam consumption and good technology effect, the effect of overcoming thermal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The production of recombinant human growth hormone rhGH is based on Escherichia coli as raw material, after inoculation, cultivation, screening and other steps to obtain the strains that meet the requirements, and then it is worthwhile after fermentation, separation, freeze-thaw cracking, extraction, separation and purification. Since Escherichia coli is used as engineering bacteria in the production process, the wastewater discharged from the production process (including liquid preparation wastewater, equipment site cleaning wastewater, etc.) contains Escherichia coli, which has biological activity, and heat sterilization is now used to remove its activity.

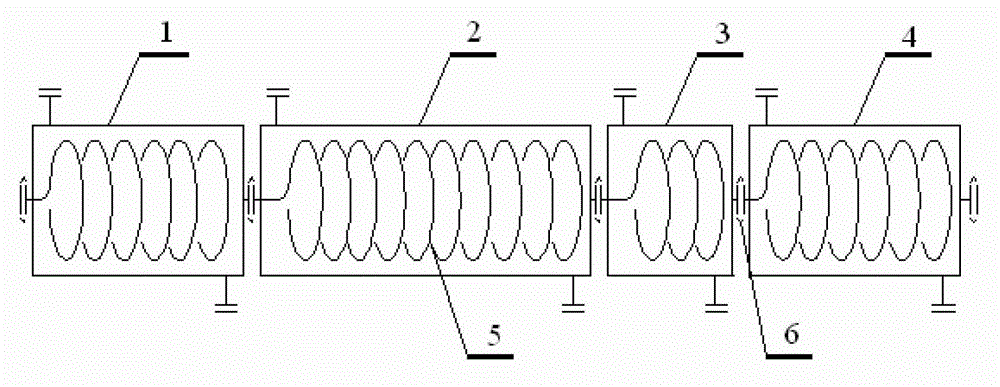

[0037] use figure 1 The UHT sterilizer shown, treats biological wastewater containing E. coli. The ultra-high temperature sterilizer uses saturated industrial steam for heating, which makes the microbial protein coagulate and denature, thus losing its original biological activity.

[0038] In the ultra-high temp...

Embodiment 2

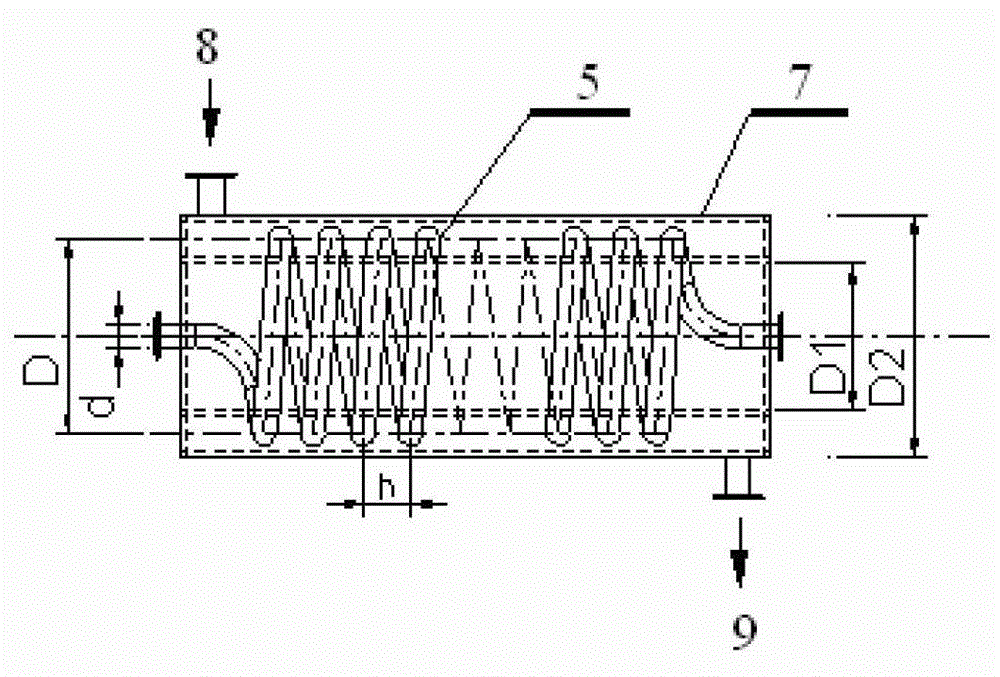

[0042] Same as [Example 1], except that the shell side is not a jacket, but a sleeve. The heating steam directly enters the sleeve for heating, the outlet temperature of the preheating zone is 95°C, the temperature of the sterilization zone is 121°C, and the temperature of the holding zone is 116°C; the residence time in the holding zone is 10 seconds.

[0043] Biopharmaceutical waste water 9 m per day 3 , processing 1 m per hour 3 Biological wastewater is heated with 0.2MPa, 133°C saturated industrial steam, and the consumption of heating steam is 188kg / h. Since the shell side does not adopt the jacket form, the steam fills the entire space immediately after entering the shell side, and there is no directional flow under the guidance of the conventional shell side, so the heat transfer efficiency is 11% lower than that of [Example 1]. The heat exchange area is correspondingly increased to 4.4m 2 . The total length of the heat exchange tube is L1=38m, and the total length ...

Embodiment 3

[0046] Same as [Example 1], except that the diameter of the spiral heat exchange tube is d=25mm, the diameter of the spiral heat exchange tube is D=300mm, d:D=1:12, the length of the heat exchange tube in each zone is L=57m, and the total residence time is 100 seconds. The pitch of the spiral tube is h=32mm, d:h=1:1.25, the inner diameter of the shell side D1=250mm, the outer diameter D2=350mm, and the total length of the heat exchanger is 2.2m.

[0047] The equipment of the invention can continuously treat waste water; the operating environment has no thermal pollution; the heating steam does not directly contact the waste water, and does not cause secondary pollution. Since the invention reduces the diameter of the heat exchange pipe and increases the fluid velocity in the pipe, it is beneficial to improve the heat transfer efficiency and shorten the residence time of the fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com