Preparation method of solvent-induced reversibly oriented transformation conjugated polymer and carbon nano tube composite film

A carbon nanotube composite and conjugated polymer technology, which is applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as agglomeration and composite materials that cannot produce effects, and achieve improved deformation ability, Excellent electrical properties, the effect of avoiding structural defects and stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

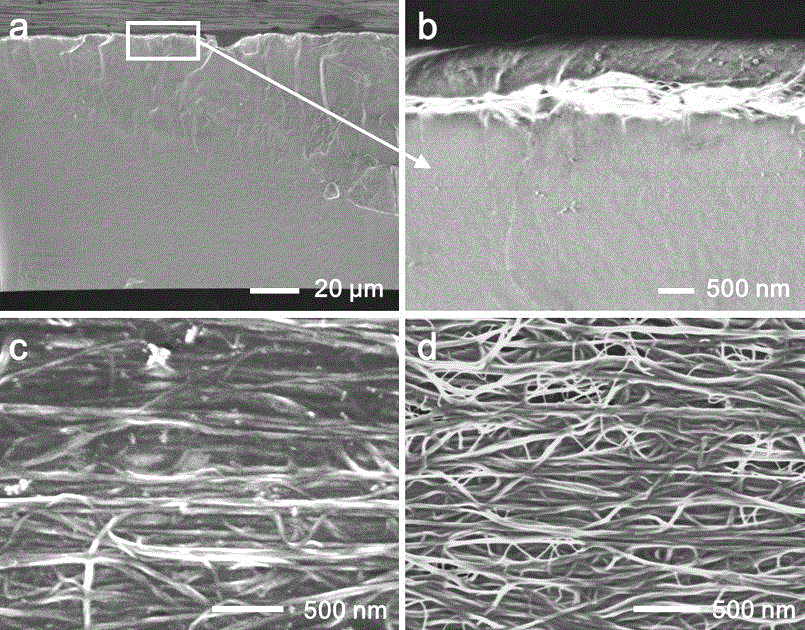

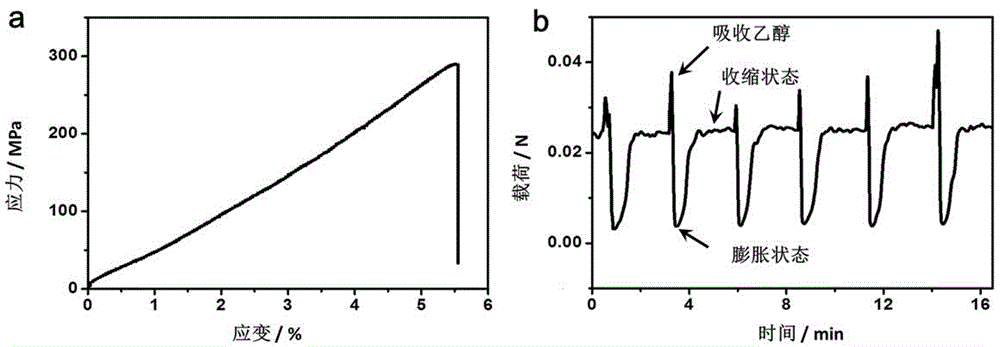

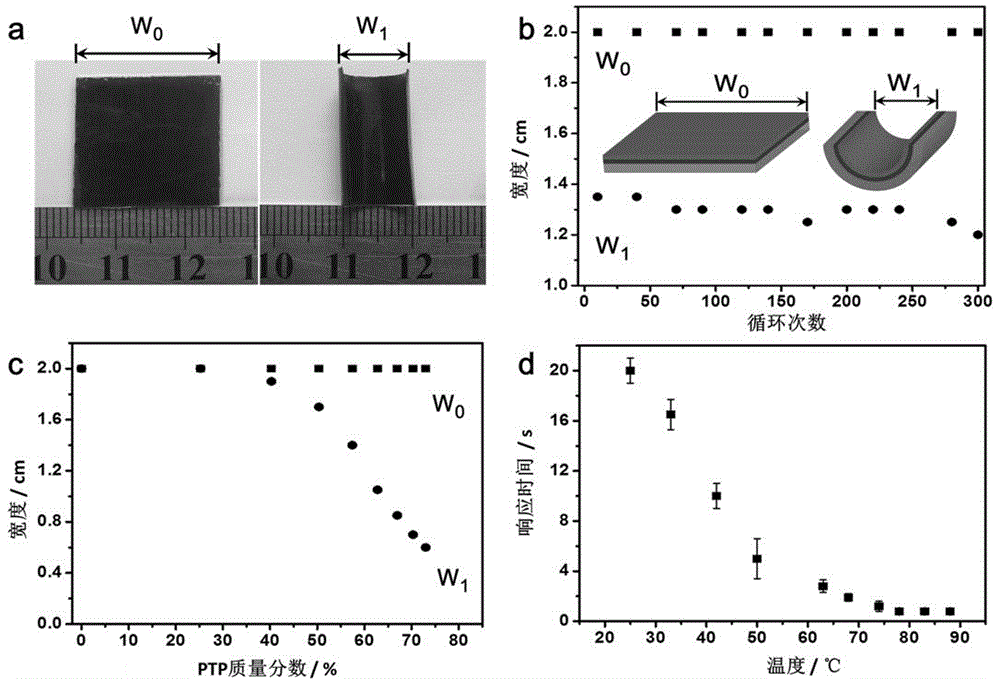

Embodiment 1

[0036] The flexible substrate is PDMS, and the PDMS prepolymer and curing agent are evenly mixed at a mass ratio of 10:1, evenly spread on the glass substrate with a thickness of 120 μm, and cured in an oven at 80°C for 2 hours. A highly oriented carbon nanotube film was prepared by dry spinning and fixed on a PDMS glass substrate with 10 carbon nanotube layers. A 1.5mg / ml PTP toluene solution was spin-coated on the aligned carbon nanotubes, and the rotation speed was divided into two stages, 1000r for 15s and 1500r for 20s. After the solvent evaporates, the composite film is peeled off from the glass sheet and cut into 1*1cm squares. Place the sample in ethanol solution and flatten it instantly. Take out the sample, and when the ethanol is completely volatilized, the sample is automatically bent along the axial direction perpendicular to the carbon nanotube, and the width of the opposite side of the bend is 0.75 cm. This solvent-induced directional deformation can be repeat...

Embodiment 2

[0038] The flexible substrate is PDMS, and the PDMS prepolymer and curing agent are evenly mixed at a mass ratio of 10:1, and evenly spread on the glass sheet with a thickness of 160 μm. The highly oriented carbon nanotube film was prepared by dry spinning and fixed on a glass substrate with 5 carbon nanotube layers. A 1.5mg / ml PTP toluene solution was spin-coated on the aligned carbon nanotubes, and the rotation speed was divided into two stages, 1000r for 15s and 1500r for 20s. The composite method of carbon nanotubes and PTP was repeated 5 times to prepare a composite film with a total of 30 layers of carbon nanotubes. Peel it off the glass sheet and cut into 2*2cm squares. Place the sample in ethanol solution and flatten it instantly. After the ethanol is completely volatilized, the composite film is automatically bent along the direction perpendicular to the axial direction of the carbon nanotubes, and the width of the opposite side of the bend is 0.85 cm. This solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com