A novel carbon-based desulphurization catalyst and a preparation method thereof

A desulfurization catalyst, carbon-based technology, applied in the field of carbon-based desulfurization catalyst and its preparation, can solve the problems of active components loss of desulfurization ability, weak desulfurization ability, low sulfur capacity, etc., to solve the problem of sharp decline in desulfurization activity and improve life , The effect of reducing the corrosion resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

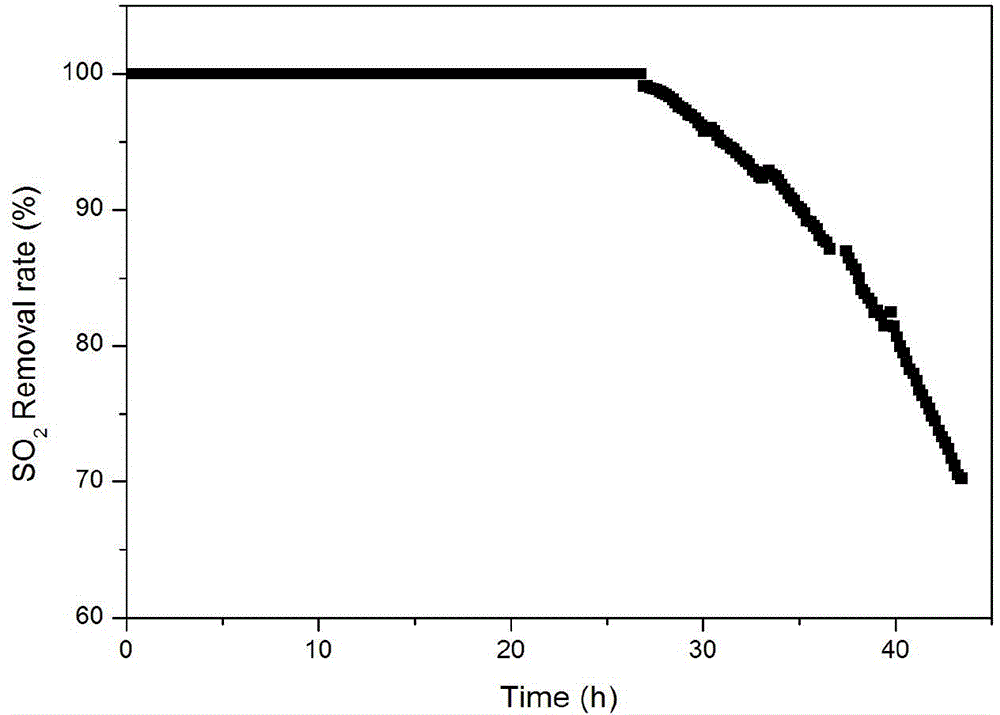

[0024] Take 10g of cerium-zirconium solid solution powder with a molar ratio of 0.5 to cerium and zirconium elements, 220g of coal powder, and 113g of coal tar. First, put the cerium-zirconium solid solution powder and coal powder in a kneader and mix them at room temperature (about 30°C) for about 30 minutes. After fully mixing, add coal tar for kneading, extrude into a columnar material (diameter 6mm) under a pressure of 10MPa, then dry it at room temperature (about 30°C) for about 3 hours, and then dry it at about 105°C for about 12 hours. Cut the dried columnar material into 4-6mm long material sections, carbonize at about 500°C for about 1.5h, and then activate with water vapor as an activator at about 900°C for about 4h to obtain a desulfurization catalyst. The average compressive strength of the catalyst reaches 164Pa, and the concentration of sulfur dioxide is about 3500mg / m 3 , the temperature is about 150°C, the humidification temperature is about 60°C (the water vap...

Embodiment 2

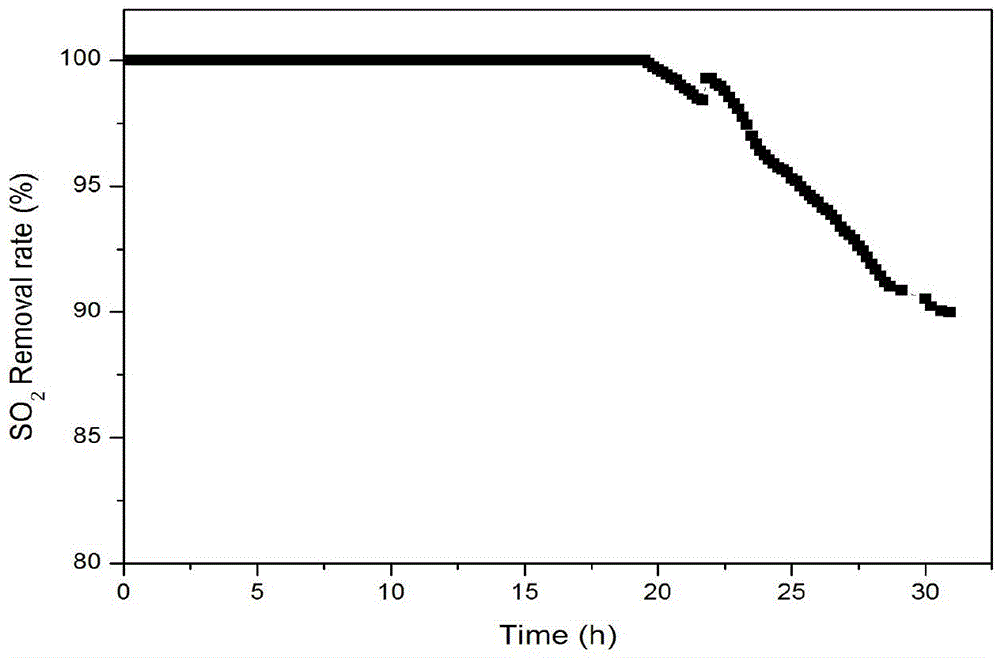

[0026] Take 32.9g of cerium-zirconium solid solution powder with a molar ratio of cerium and zirconium elements of 1.0, 165g of coal powder, and 98g of coal tar. First, put the cerium-zirconium solid solution powder and coal powder in a kneader and mix them at room temperature (about 20°C) for about 40 minutes , after fully mixing, then add coal tar for kneading, extrude into a columnar material strip (6mm in diameter) under a pressure of 10MPa, then dry it at room temperature (about 20°C) for about 4 hours, and then dry it at about 90°C for 15 hours about. Cut the dried strips into 4-6mm long material sections, carbonize at about 400°C for about 2 hours, and then activate with water gas as an activator at about 800°C for about 6 hours to obtain a desulfurization catalyst. The average compressive strength of the catalyst reaches 156Pa, and the concentration of sulfur dioxide is about 7924mg / m 3 , the temperature is about 120°C, the humidification temperature is about 70°C (th...

Embodiment 3

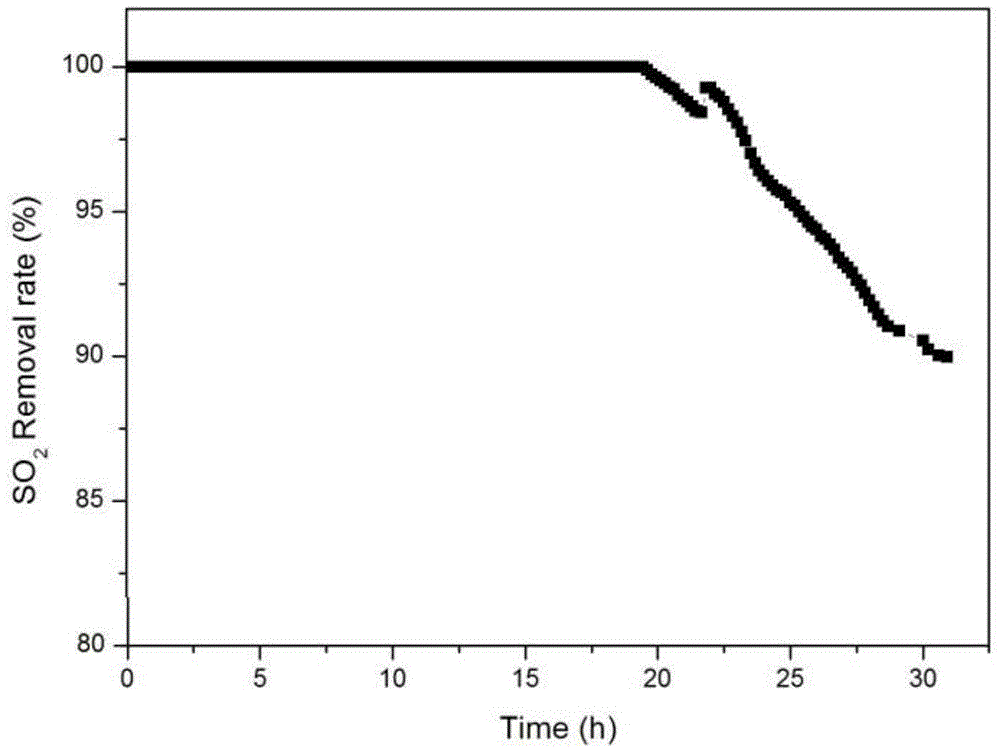

[0028] Take 40g of cerium-zirconium solid solution powder with a molar ratio of cerium and zirconium elements of 1.5, 190g of coal powder, and 116.5g of coal tar, first place the cerium-zirconium solid solution powder and coal powder in a kneader, and mix them at room temperature (about 15°C) for about 40 minutes , after fully mixing, then add coal tar for kneading, extrude into a columnar material strip (6mm in diameter) under a pressure of 10MPa, then dry it at room temperature (about 15°C) for 8 hours, and then dry it at about 120°C for about 10 hours . Cut the dried strips into about 4-6mm long sections, carbonize at about 600°C for about 1 hour, and then activate the mixed gas of water vapor and carbon dioxide as an activator at about 1000°C for about 6 hours to obtain a desulfurization catalyst. The average compressive strength of the catalyst reaches 156Pa, and the concentration of sulfur dioxide is about 7150mg / m 3 , the temperature is about 80°C, the humidification t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com