Yarn fluffing, pilling and grinding bobbin filled with high polymer and its preparation and application

A technology of pilling and scratching, which is applied in the preparation of test samples, the use of mechanical devices, textiles and papermaking, etc. It can solve the problems of winding yarn sheet stability and simulating fabric structural characteristics. , to achieve the effect of preventing tumbling and moving, preventing yarn displacement and tumbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

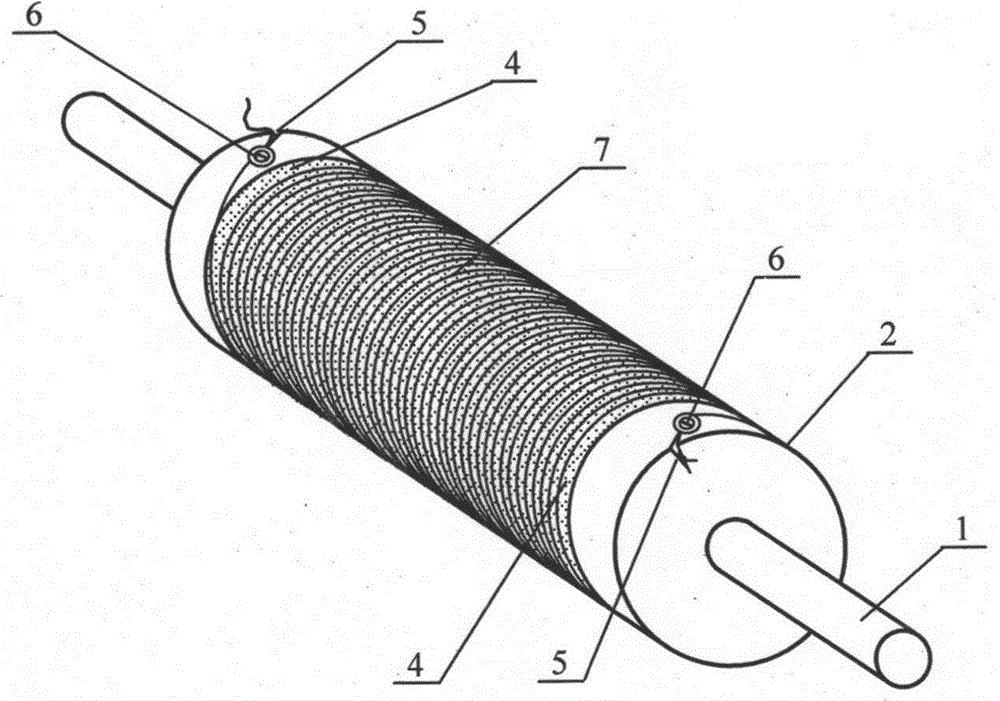

[0033] The steps of the preparation method of the yarn fluffing and pilling milled yarn cylinder filled with the above-mentioned high polymer are as follows:

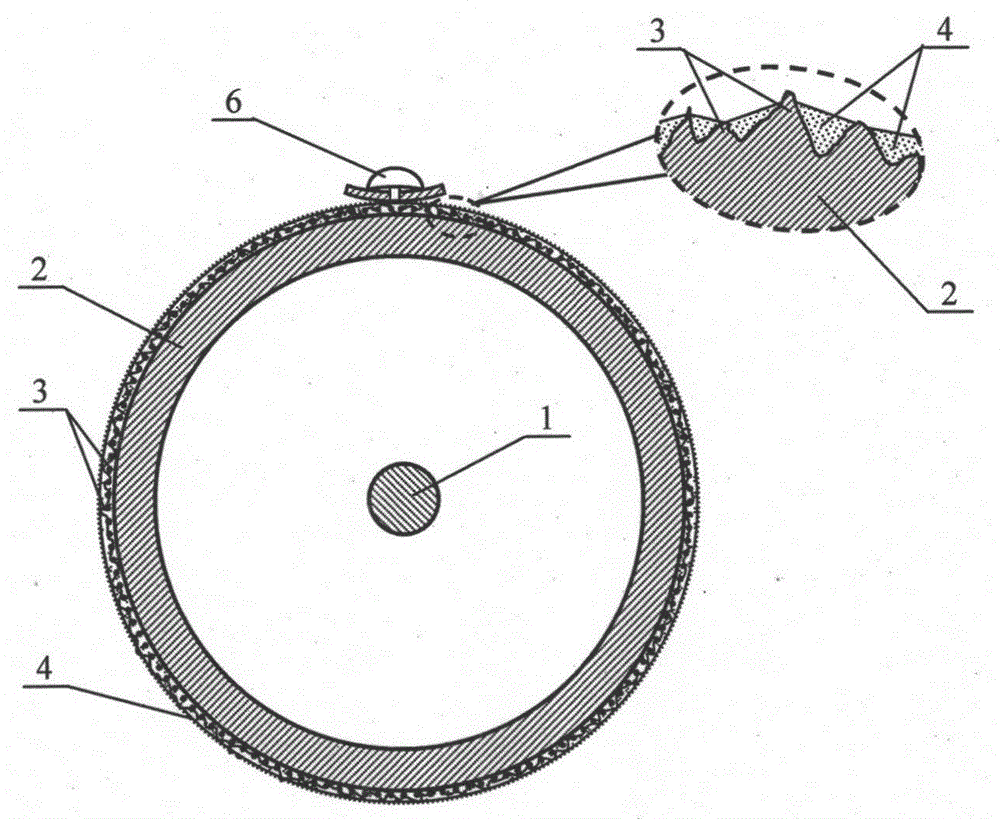

[0034] The first step is to engrave and grind the metal cylinder. The outer surface of the metal cylinder 2 is engraved with directional wear marks 3 with a depth and spacing of 20 μm to 2 mm, wherein the directionality refers to one of parallel, orthogonal, and diamond-shaped wear marks, and the wear marks 3 The protruding point can rigidly insert or withstand the yarn 7, while the concave part can rigidly hold the yarn 7 and restrict the yarn 7, with more contact surfaces and holding points, and at the same time when the thicker scuff marks 3 , it can take into account that the parallel scratch marks 3 can provide the effect of simulating the fabric structure, while the vertical thicker scratch marks 3 can prevent the yarn 7 from shifting and rolling.

[0035]The second step is to scrape the polymer. The solvent-sol...

Embodiment 1

[0039] Adopt the preparation method of the present invention to obtain the yarn cylinder that the surface engraved rhombus direction, lateral depth and spacing are 1.5mm, oblique depth and spacing are 200 μm, and then scrape coating the polyurethane solution with a thickness of 1mm and solidify to form a film, its surface forms The surface structure is composed of rigid and flexible components filled with flexible polymers in the rigid scratches. The double-strand yarn of full wool with a yarn number of 16.4tex and 2×8.2tex is wound on the bobbin with a tension of 6cN. On the surface, the winding yarn 7 is rigidly restricted by the protruding part of the scuff marks in the pilled scuffed yarn, and is held by a large area due to the flexible depression of the solvent-soluble polymer scraped in the scuff marks. There is no movement and tumbling, which can make the grinding yarn of the winding layer more stable and applicable to a wider range. There is no dislocation and overlapp...

Embodiment 2

[0041] Adopt the preparation method of the present invention to obtain the yarn bobbin that the surface is engraved in the orthogonal direction, the depth and the distance are all 700 μm, and then the rubber solution with a thickness of 500 μm is scraped and solidified to form a film, and the surface forms a flexible high polymer filled with rigid engraving The surface structure of rigid and soft components in the traces is combined. The wool acrylic blended yarn with a yarn number of 11.1tex is wound on the surface of the bobbin with a tension of 9cN. Restricted by the rigidity of the protruding parts of the scratches, and the flexible depression of the rubber coated in the scratches produces a large area of grip without moving and rolling, which can make the grinding yarn of the winding layer more stable and suitable for the surface wider. There is no dislocation and overlapping of the winding yarn 7 in the whole close-packed winding. The friction along the axis of windin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com