Large-diameter earth pressure balance shield machine

An earth pressure balance and shield machine technology, applied in the field of shield machines, can solve the problems of reducing the working efficiency of the shield machine, decreasing the driving speed, and the deflection of the tunnel axis, so as to speed up the propulsion speed and work efficiency, and reduce the propulsion force. , the effect of reducing the chance of slush cake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

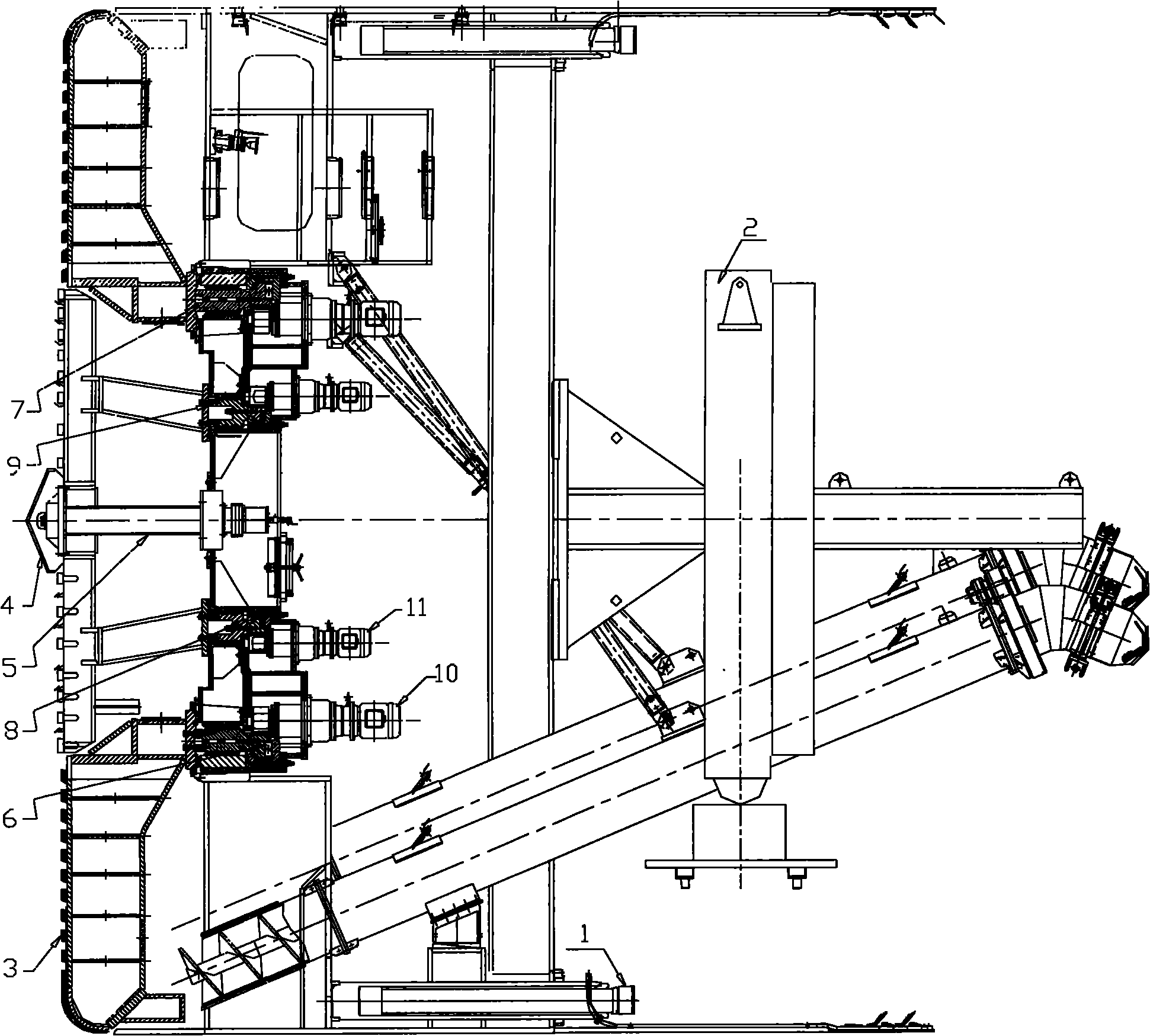

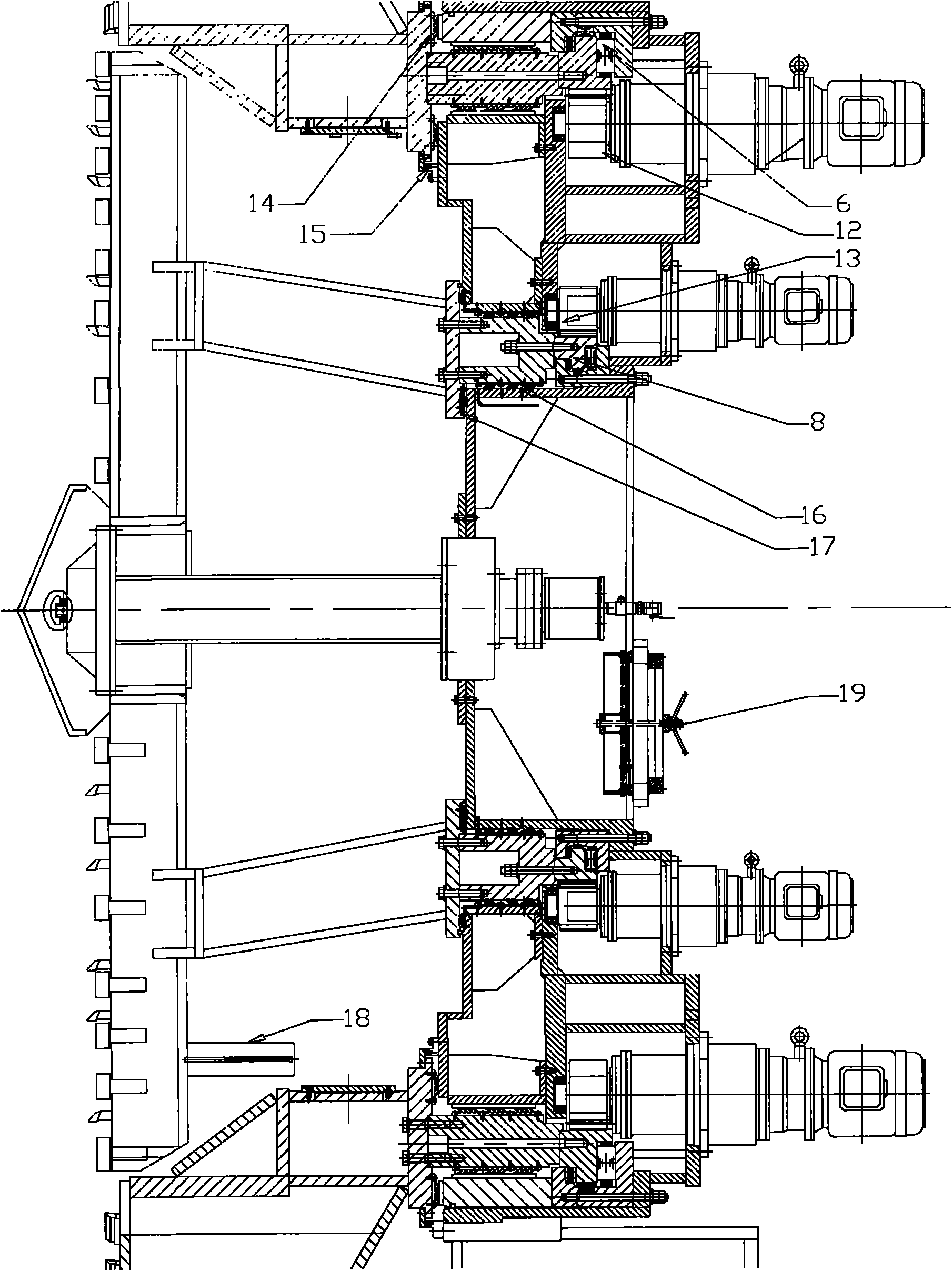

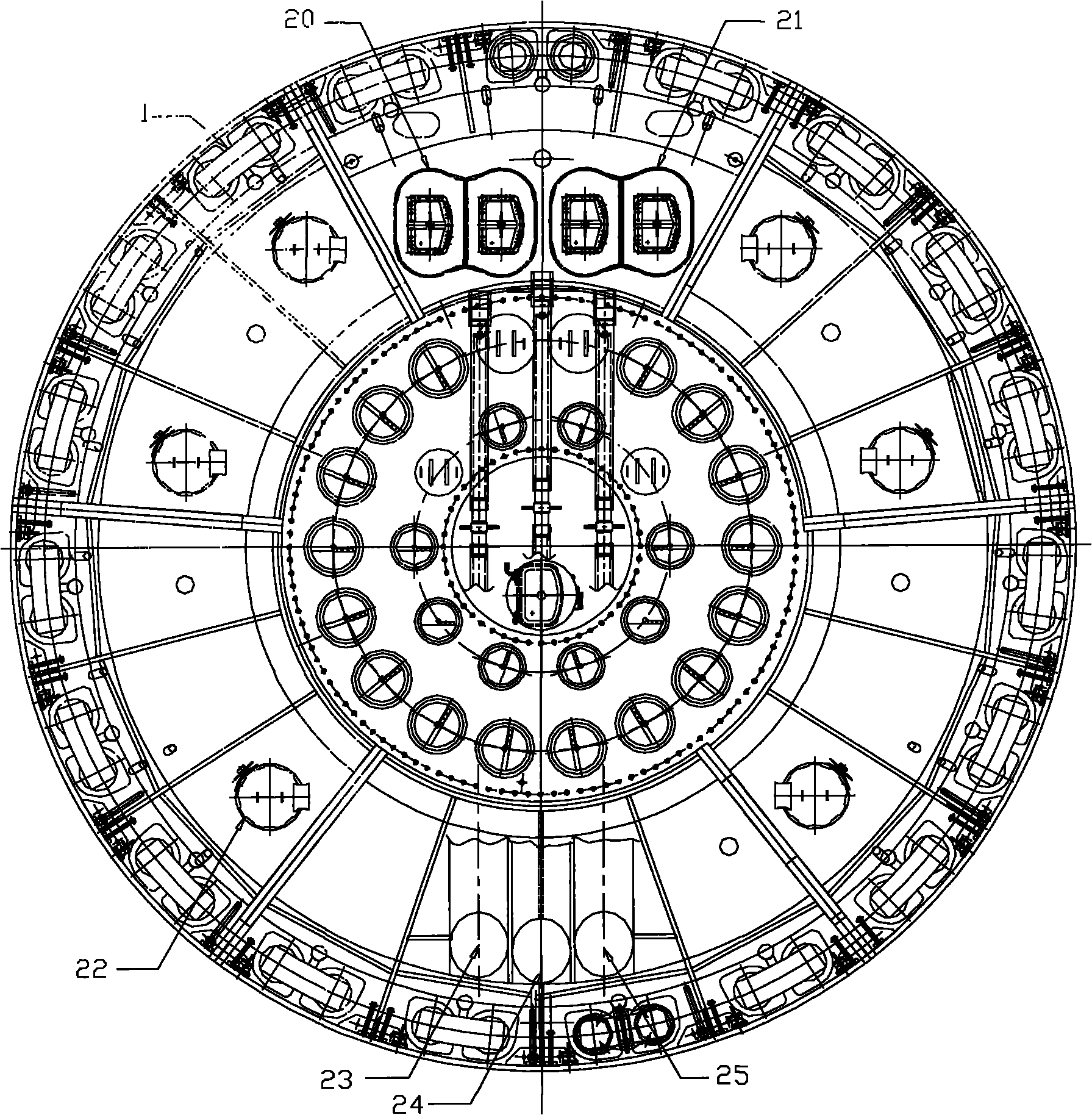

[0035] Such as Figure 1 ~ Figure 4 As shown, a large-diameter (above 11m) earth pressure balance shield machine designed based on Shanghai's geological conditions includes a cutter head, a cutter head drive unit, a propulsion cylinder 1, an assembly machine 2, a screw conveyor, and a frame.

[0036] The cutter head is a double cutter head, and the double cutter head includes an integral peripheral large cutter head 3 and an independent central cutter head 4. The outer peripheral large cutter head 3 includes eight groups of spoke panel knife arms 31, and the independent central cutter head 4 and the central cutter head The center rotation 5 is connected, and the independent center cutter head 4 includes six sets of spoke panel knife arms 41, and the technical parameters of the two are shown in Table 1:

[0037] Table 1 The technical parameters of the peripheral large cutterhead and independent central cutterhead

[0038] Peripheral cutter head

technical parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com