Thermosetting resin composition

A resin composition, thermosetting technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problem of improper proportion of bismaleimide resin, compatibility, and increase the difficulty of implementation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

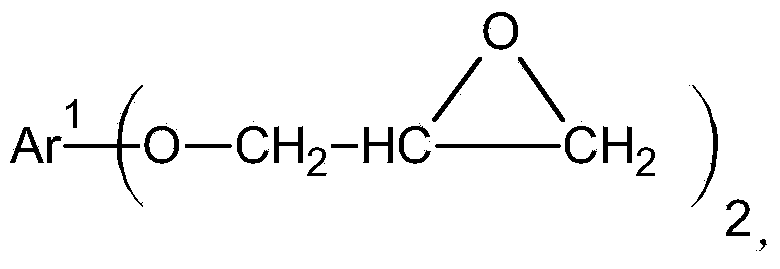

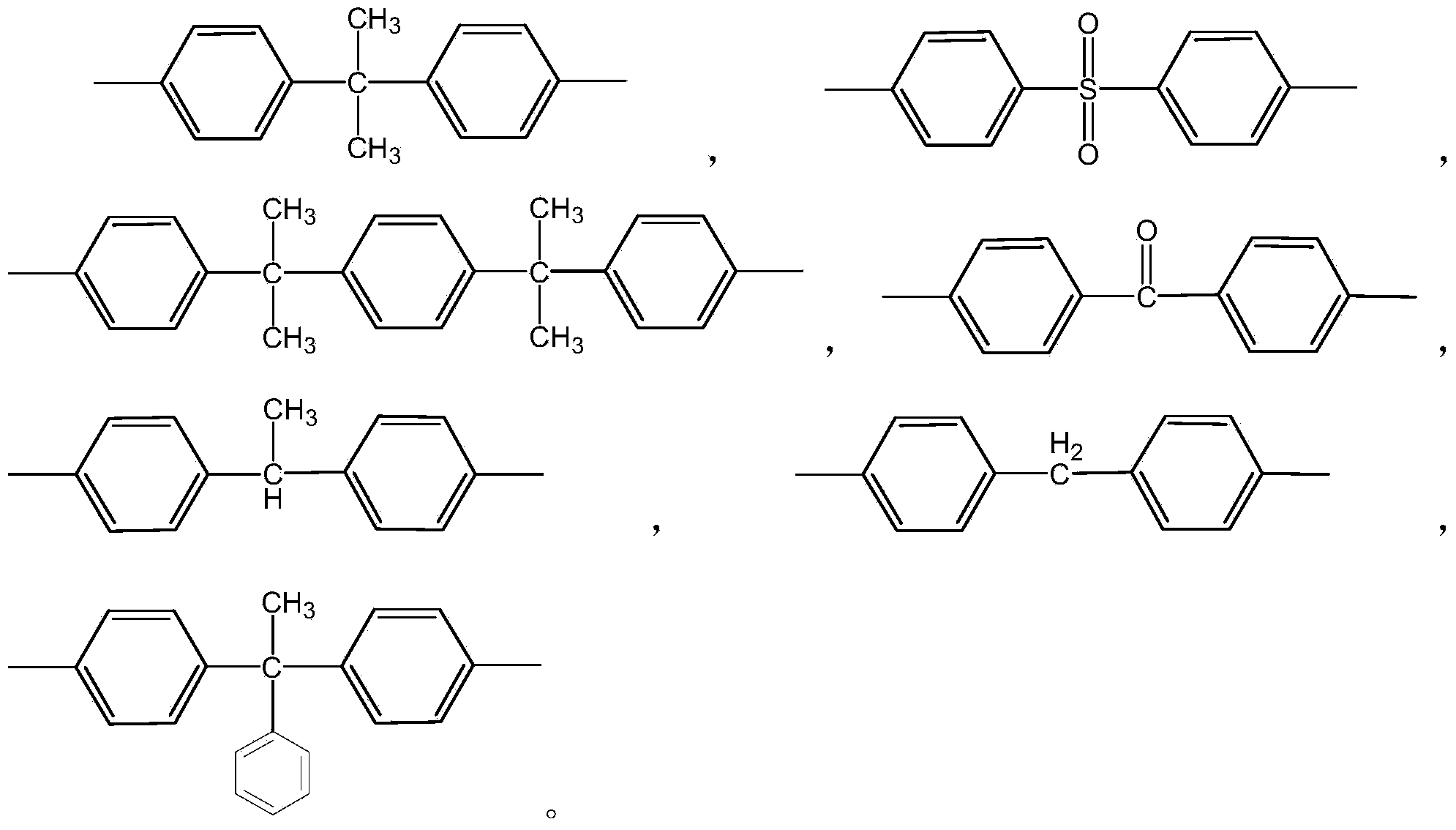

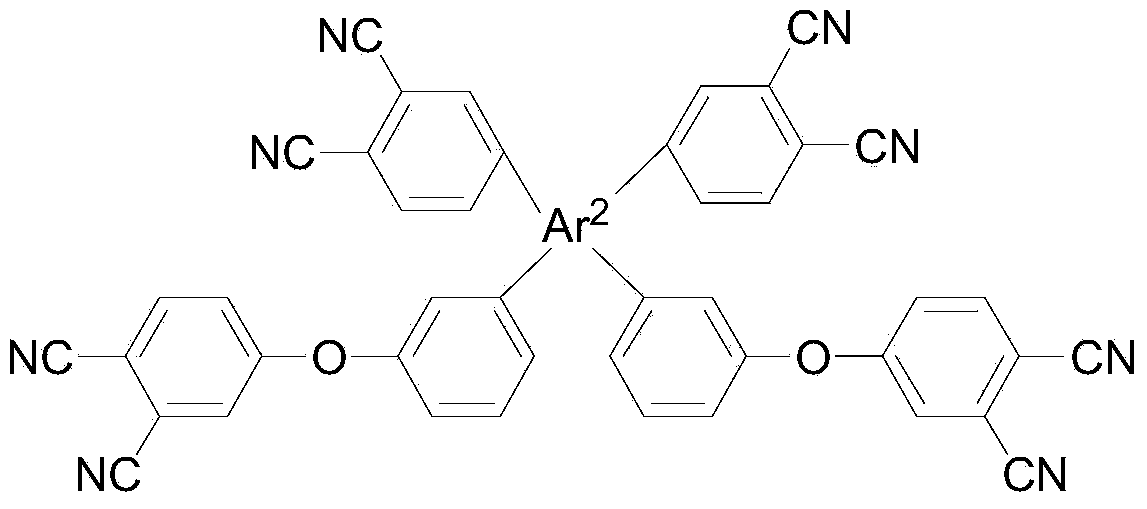

Method used

Image

Examples

Synthetic example 1

[0089] A kind of allyl modified bis-horse resin prepolymer is prepared by the following method:

[0090] Mix 4,4'-diphenylmethane bismaleimide resin and diallyl bisphenol A at a mass ratio of 100:30, and react at 110°C for 20 minutes to obtain allyl-modified bismaleimide resin The prepolymer is denoted as Shuangma 1.

Synthetic example 2

[0092] A kind of allyl modified bis-horse resin prepolymer is prepared by the following method:

[0093] Mix 4,4'-diphenylisopropyl bismaleimide resin and allyl phenoxy resin at a mass ratio of 100:120, and react at 160°C for 30 minutes to obtain allyl-modified bismaleimide The resin prepolymer is Shuangma 2.

Synthetic example 3

[0095] A kind of allyl modified bis-horse resin prepolymer is prepared by the following method:

[0096] Mix 4,4'-diphenylsulfone bismaleimide resin and diallyl diphenyl ether at a mass ratio of 100:15, and react at 120°C for 120 minutes to obtain allyl-modified bismaleimide resin The prepolymer is Shuangma 3.

[0097] Embodiments 1-11 provide 11 thermosetting resin compositions; Comparative Examples 1-7 provide 7 resin compositions for comparison with the resin compositions provided in Examples 1-11; said Examples 1-6 The formulations of the resin compositions provided are shown in Table 1; the formulations of the resin compositions provided in Examples 7-11 are shown in Table 2; the formulations of the resin compositions provided in Comparative Examples 1-7 are shown in Table 3.

[0098] The formula of the resin composition that table 1 embodiment 1~6 provides

[0099]

[0100]

[0101] The formula of the resin composition that table 2 embodiment 7~11 provides

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com