A kind of preparation method of high-efficiency zinc phosphate micro-nano antiseptic

A high-efficiency zinc phosphate, micro-nano technology, applied in the direction of anti-corrosion coatings, nanotechnology, nanotechnology, etc., can solve the problems of difficult to take into account the crystallinity, difficult to take into account the particle size, etc., to promote dissolution, promote formation, and enhance mass transfer and the effect of the heat transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

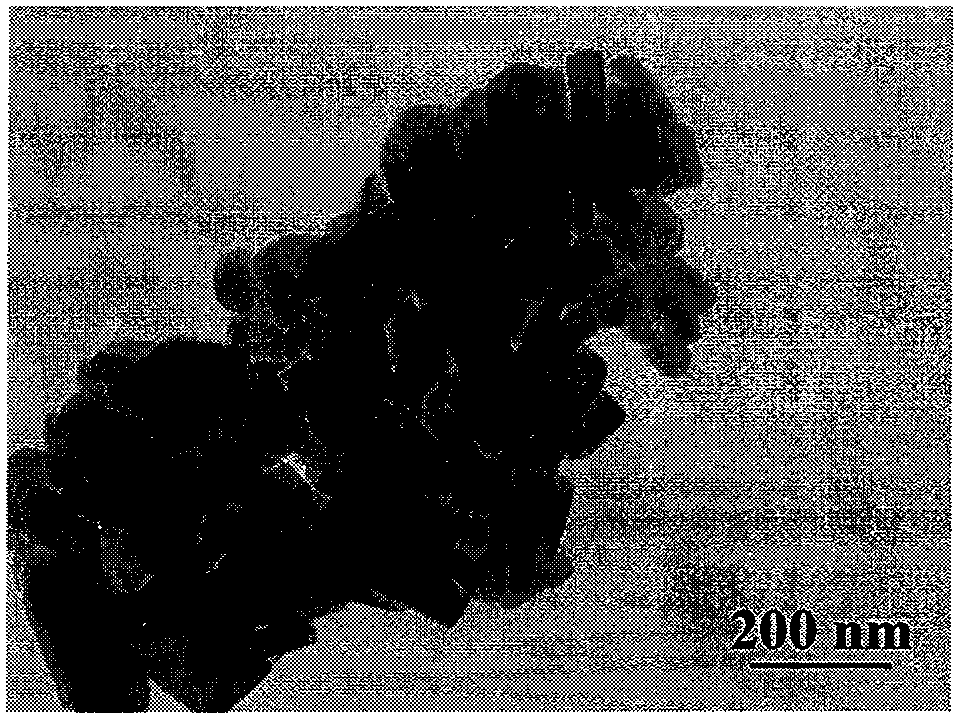

Embodiment 1

[0021] Weigh 0.6g CTAB in a beaker, add 200mL deionized water, after it is completely dissolved, add 300mL of 1mol / L Zn(NO 3 ) 2 Solution, stir well to make it evenly mixed. Under ultrasonic working condition, slowly add 200mL of 1mol / LNa into the beaker 3 PO 4 solution until the addition is complete. The precipitate was transferred to the reaction kettle, ultrasonically cavitated for 24 hours, the power was 200W, and the temperature of the water bath was controlled at 150°C. After the reaction, wash and filter the precipitate, place it in a microwave reactor and dry it for 1 hour, and adjust the power to 300W to obtain zinc phosphate micro-nano powder. The particle size of the product is about 230nm, and the anticorrosion time is about 1015 hours.

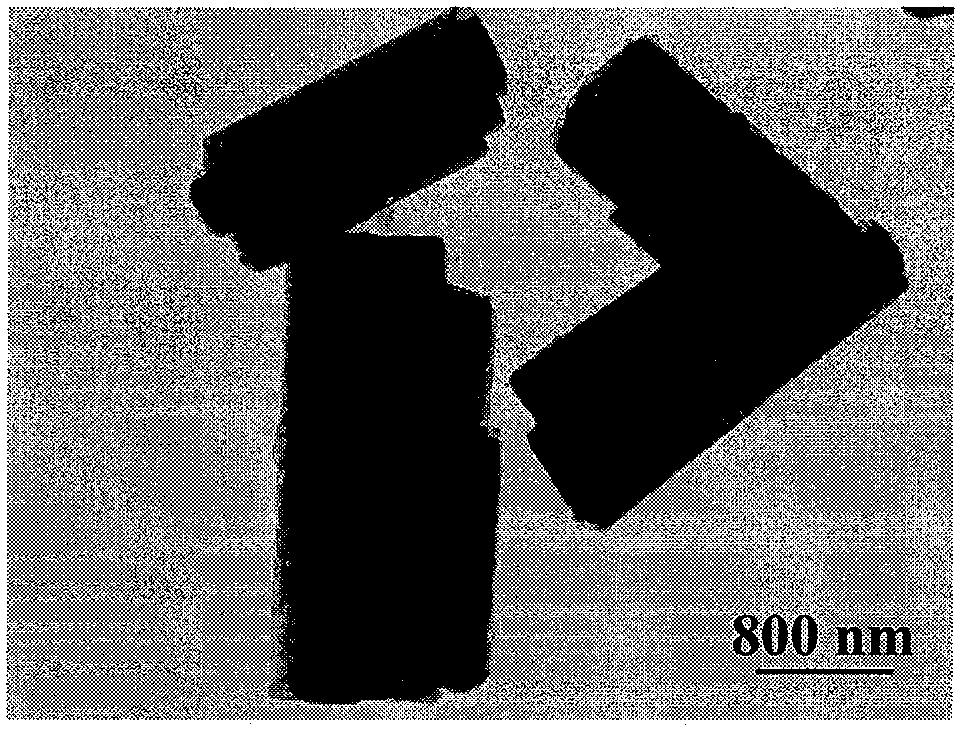

Embodiment 2

[0023] Weigh 0.6g of polyethylene glycol in a beaker, add 200mL of deionized water, and after it is completely dissolved, add 300mL of 1mol / L Zn(NO 3 ) 2 Solution, stir well to make it evenly mixed. Under ultrasonic working conditions, slowly add 200mL of 1mol / L Na to the beaker dropwise 3 PO 4 solution until the addition is complete. The precipitate was transferred to the reaction kettle, ultrasonically cavitated for 24 hours, the power was 600W, and the temperature of the water bath was controlled at 150°C. After the reaction, wash and filter the precipitate, place it in a microwave reactor and dry it for 8 hours, and adjust the power to 600W to obtain zinc phosphate micro-nano powder. The particle size of the product is about 200nm, and the anticorrosion time is about 1049 hours.

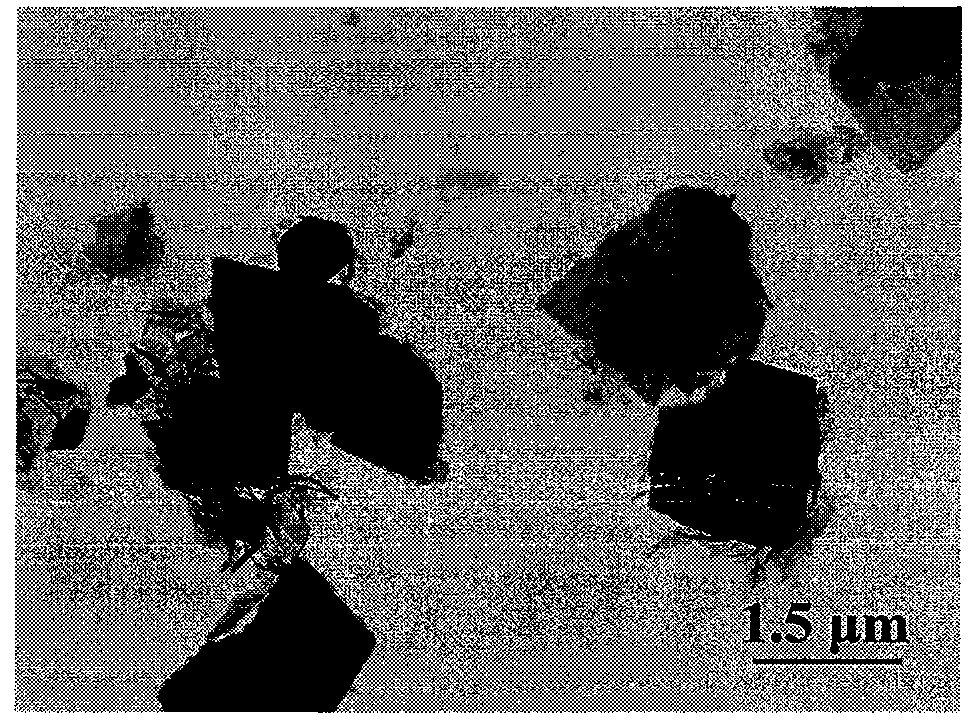

Embodiment 3

[0025] Weigh 2.4g Triton x-100 in a beaker, add 200mL deionized water, after it is completely dissolved, add 300mL of 1mol / L Zn(NO 3 ) 2 Solution, stir well to make it evenly mixed. Under ultrasonic working conditions, slowly add 200mL of 1mol / L Na to the beaker dropwise 3 PO 4 solution until the addition is complete. The precipitate was transferred to the reaction kettle, ultrasonically cavitated for 24 hours, the power was 1000W, and the temperature of the water bath was controlled at 150°C. After the reaction, the precipitate was washed and filtered by suction, then dried in a microwave reactor for 1 hour, and the power was adjusted to 400W to obtain zinc phosphate micro-nano powder. The particle size of the product is about 210nm, and the anticorrosion time is about 1031 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com