Method for producing synthesis gas by catalytically reforming coal, natural gas and carbon dioxide

A catalytic reforming and carbon dioxide technology, applied in the field of coal chemical industry, can solve the problems of fixed bed catalyst carbon deposition, uneven catalyst bed temperature, sintering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Example 1: Synthesis gas produced by catalytic reforming of coal, natural gas and carbon dioxide

[0085] The implementation steps of this embodiment are as follows:

[0086] The coal composition used in this example is shown in Table 1, and the natural gas composition is shown in Table 2 on a dry basis. CO 2 The dry base composition by volume is shown in Table 3.

[0087] Table 1: Analysis results of coal composition

[0088]

[0089] Table 2: Analysis results of dry base composition of natural gas

[0090]

[0091] Table 3: CO 2 Dry base composition analysis results

[0092]

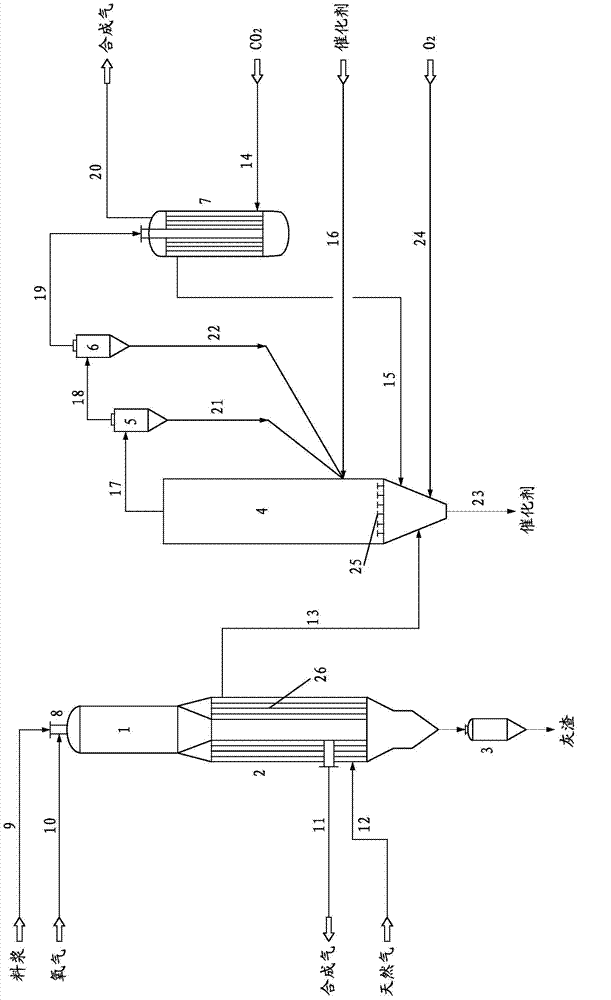

[0093] This embodiment follows the attached figure 1 The process flow diagram shown is performed.

[0094] The specific implementation steps are as follows:

[0095] The raw coal with 10% moisture content is about 19371.62kg / h, which is made into a slurry with 9746.26kg / h of water and additives. The slurry flow is about 29208.53kg / h and the concentration is about 60%. The slurry is sent to the nozzle 8 th...

Embodiment 2

[0102] Example 2: The present invention is implemented with coal from a certain area as the main raw material. The analysis data of raw coal is shown in Table 4, and the composition of natural gas is shown in Table 5 on a dry basis. CO 2 The dry base composition by volume is shown in Table 6.

[0103] Table 4: Analysis results of raw coal composition

[0104]

[0105] Table 5: Analysis results of natural gas dry base composition

[0106]

[0107] Table 6: CO 2 Dry base composition analysis results

[0108]

[0109] The specific implementation steps of this embodiment are the same as that of Example 1. The coal from a certain place is selected as the raw material, and the raw coal is about 9377.18kg / h, and the slurry is made with water and additives with a concentration of about 62% and a flow rate of 13722.7kg / h. 5020.96Nm 3 / h, the slurry and oxygen are sprayed into the gasification furnace 1 through the nozzle 8. The gasification reaction pressure is 6.5MPa and the temperature is 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com