Preparation method of iron-based amorphous alloy-copper multilayer composite plate

An iron-based amorphous alloy and multi-layer composite technology, which is applied in the direction of metal layered products, chemical instruments and methods, lamination, etc., can solve the problem of insufficient welding preparation efficiency and feasibility of multi-layer composite materials, unable to meet welding requirements, High equipment requirements and other issues, to achieve the effect of increasing element diffusion distance, small rheological stress, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

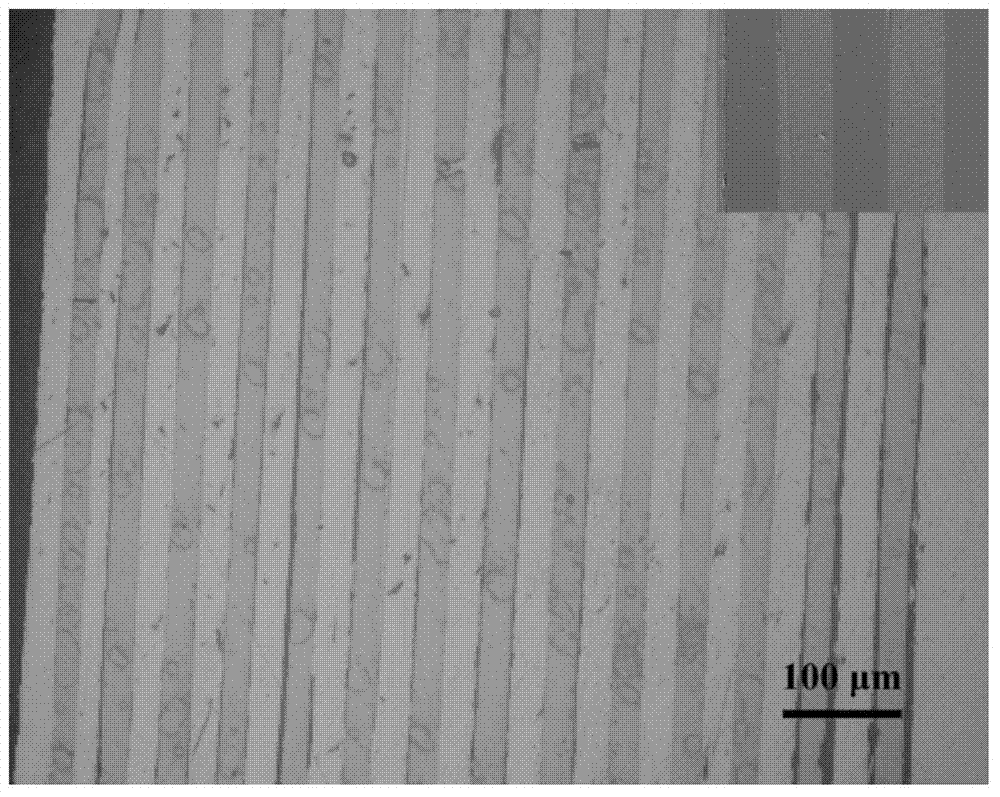

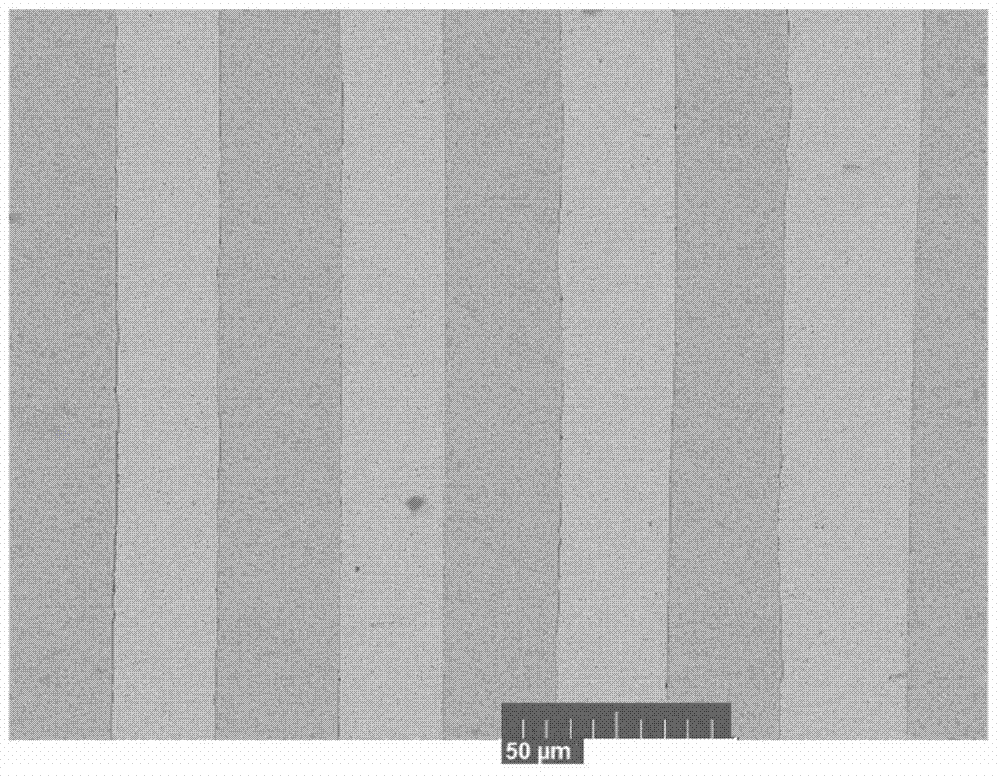

[0024] This embodiment is an iron-based amorphous foil (Fe 78 Si 9 B 13 ) and copper foil for the preparation of 40-layer composite panels. The dimensions of the iron-based amorphous foil and copper foil are both 100×100mm 2 , with a thickness of 30 μm.

[0025] Step 1, pretreatment: Use 20% hydrochloric acid alcohol solution cleaning and ultrasonic cleaning to remove the oxide layer on the surface of iron-based amorphous alloy foil and copper foil, then put them in absolute alcohol for cleaning, and dry them with cold air. Stack 20 layers of iron-based amorphous foils and 20 layers of copper foils in the order of ABAB···AB, and wrap them with 2 sheets of copper foil with a thickness of 50 μm in a 90° cross form.

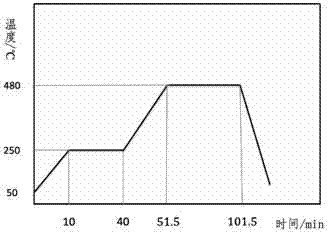

[0026] Step 2, pre-diffusion connection: put the sample into the vacuum diffusion welding machine, and the vacuum degree is pumped to 5×10 -3 Pa~7×10 -3 Pa, the temperature of the vacuum diffusion welding machine is raised to 400-650°C by means of gradient hea...

Embodiment 2

[0033] This embodiment is an iron-based amorphous foil (Fe 78 Si 9 B 13 ) and copper foil 40 composite sheet preparation method. The size of the iron-based amorphous foil and copper foil is 100×100mm 2 , with a thickness of 30 μm.

[0034] Step 1, pretreatment: Use 20% hydrochloric acid alcohol solution cleaning and ultrasonic cleaning to remove the oxide layer on the surface of the iron-based amorphous alloy foil and copper foil, then put it in absolute alcohol for cleaning, and dry it with cold air. Stack 20 layers of iron-based amorphous alloy foils and 20 layers of copper foils in the order of ABAB · AB, and use two 50 μm thick copper foils as wrappers to wrap them in a 90° cross form.

[0035]Step 2, pre-diffusion connection: put the sample into the vacuum diffusion welding machine, and when the vacuum degree is pumped to 5×10-3Pa~7×10-3Pa, the temperature of the vacuum diffusion welding machine is raised to 400~650 ℃. Specifically: for the first time, the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com