Slab submersed nozzle controlling flowing of metal fluid

A metal fluid, immersion technology, used in metal processing equipment, manufacturing tools, casting melt containers, etc., can solve problems such as large liquid level fluctuations, affecting the heat transfer of the billet shell, and uneven heat transfer in the meniscus area. , to achieve the effect of less risk of production accidents, improved product quality, and comprehensive options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

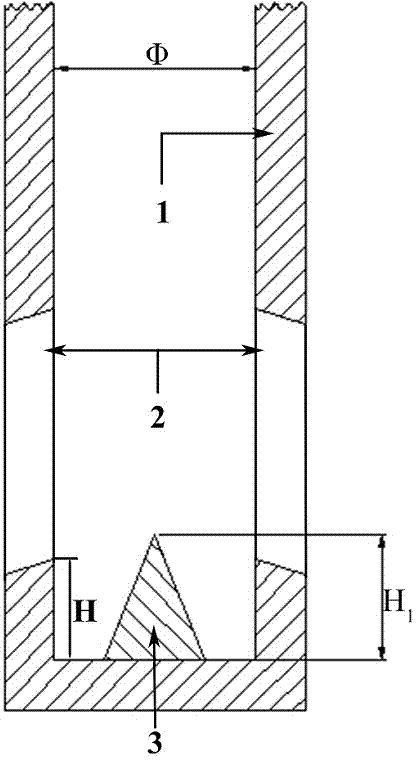

Embodiment 1

[0031] like figure 2 As shown, the flow control pyramid 3 is to place a side length L in the bottom groove 1 40mm, height H 1 It is a 70mm square pyramid, in which the two corners of the pyramid are aligned with the center line of the metal liquid spit hole on the side of the nozzle. In order to ensure the symmetry of the flow inside the nozzle, the prisms on both sides are completely symmetrical along the two diagonal lines perpendicular to each other. When the above conditions are determined, change the angle α between the two sides of the bottom of the edge 1 When changing from 5° to 45°, the shape of the pyramid will change accordingly, and at the same time, the angle of the reflecting surface of the incident stream will also change, so that after the incident stream is reflected by the pyramid, the original flow state will be changed, resulting in a After the nozzle, flow fields of different shapes are formed in the crystallizer. Changing the length L of the base and...

Embodiment 2

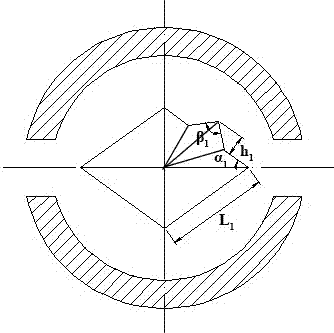

[0033] like image 3 As shown, the flow control pyramid 3 is to place a height H in the bottom groove 1 is 70mm, and the side lengths are L 1 It is a 40mm square pyramid, in which the two corners of the pyramid are aligned with the center line of the metal liquid spit hole on the side of the nozzle. The quadrangular pyramid is completely symmetrical along the center plane of the outlet and its vertical plane. On the four faces of the pyramid, add an inverted V-shaped boss respectively, the height of the bottom surface h 1 is 30mm, and the angle between the two bottom edges is β 1 is 60°. When the above conditions are determined, change the angle α between the two sides of the bottom of the edge 1 When changing from 5° to 60°, the shape of the pyramid will change accordingly, and the angle of the reflecting surface of the incident stream will also change, so that after the incident stream is reflected by the pyramid, the original speed and direction will be changed, thereb...

Embodiment 3

[0035] like Figure 4 As shown, the flow control pyramid 3 is to place a side length L in the bottom groove 1 40mm, height H 1 It is a 70mm square pyramid, and engraved on the four sides of the square pyramid with a radius r of 15mm and a chord height of h 2 10mm circular launder. Wherein the two corners of the pyramid are centered with the center line of the metal liquid spit hole on the side of the nozzle. In order to ensure the symmetry of the flow inside the nozzle, the prisms on both sides are completely symmetrical along the two diagonal lines perpendicular to each other. In this case, the inner diameter of the nozzle Φ, the depth of the closed concave bottom H, and the length of the bottom edge L 1 , Pyramid height H 1 , the angle α between the two sides of the base 1 , launder radius r, chord height h 2 For the control factors, changing one of the factors can cause the flow control boss to change, thereby producing different metal fluid outlet states and differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com