Penicillin V potassium micro-capsule and preparation method thereof

A technology for penicillin V and preparations, applied in the field of penicillin V potassium microcapsules and its preparation, can solve the problems of no antibacterial effect, etc., and achieve the effects of environmental protection, elimination of bad smell, and easy operation and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

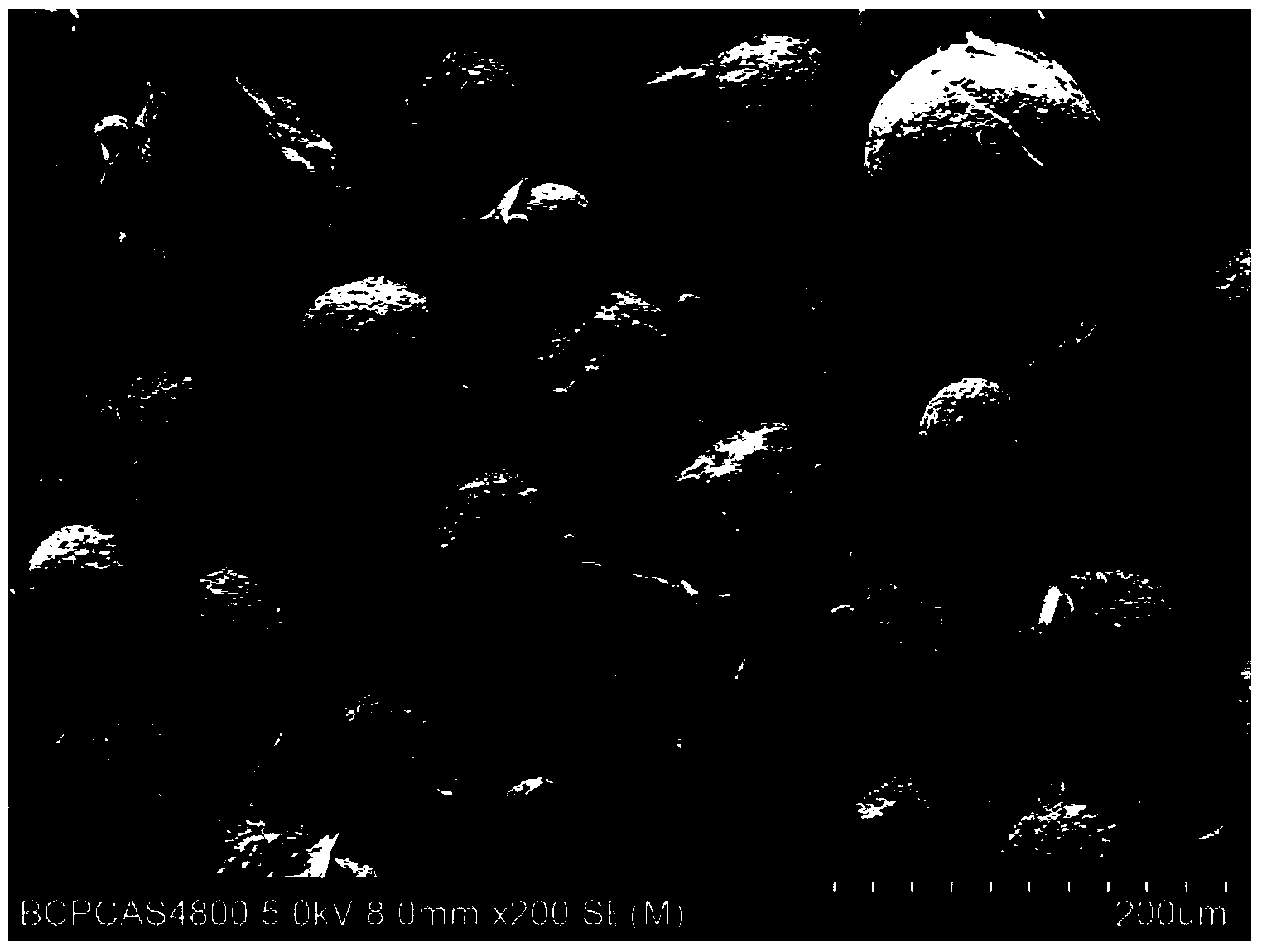

[0033] Grind ethyl cellulose to 80 mesh, penicillin V potassium to 80 mesh, accurately weigh 1 g of penicillin V potassium and 1 g of ethyl cellulose, add ethyl cellulose to 80 mL of dichloromethane under stirring until completely dissolved , to obtain solution a; penicillin V potassium was added to dissolve in solution a under stirring at a rotational speed of 400 rpm to obtain solution b, and solution b was stirred at a rotational speed of 400 rpm for 20 min. Put 800mL of water in a beaker for a water bath, control the temperature of the water bath at 35°C, add 1g of surfactant sodium lauryl sulfate while stirring to obtain solution c, add solution b to solution c, and stir at 400rpm until two The methyl chloride was completely volatilized, the solid product was filtered under reduced pressure, the microcapsules were washed 3 times with distilled water, and dried to obtain 1.76 g of dry solid powder. The particle size range is 50-700 μm, the average particle size is 131.9 μm...

Embodiment 2

[0037] Grind ethyl cellulose to 80 mesh, penicillin V potassium to 80 mesh, accurately weigh 2 g of penicillin V potassium and 1 g of ethyl cellulose, add ethyl cellulose to 80 mL of dichloromethane under stirring until completely dissolved , to obtain solution a; penicillin V potassium was added to dissolve in solution a under stirring at a rotational speed of 400 rpm to obtain solution b, and solution b was stirred at a rotational speed of 400 rpm for 20 min. Put 500mL of water in a beaker for a water bath, control the temperature of the water bath at 35°C, add 1g of surfactant sodium lauryl sulfate while stirring to obtain solution c, add solution b to solution c, and stir at 400rpm to two The methyl chloride was completely volatilized, the solid product was filtered under reduced pressure, the microcapsules were washed 3 times with distilled water, and dried to obtain 1.82 g of dry solid powder.

Embodiment 3

[0039] Ethyl cellulose was crushed to 80 meshes, penicillin V potassium was crushed to 80 meshes, 2 g of penicillin V potassium and 2 g of ethyl cellulose were precisely weighed, and ethyl cellulose was added to 150 mL of dichloromethane under stirring until completely dissolved. Obtain solution a; add penicillin V potassium to the solution a under stirring at a rotation speed of 400 rpm to dissolve to obtain solution b, and stir solution b at a rotation speed of 400 rpm for 20 min. Put 800mL of water in a beaker for a water bath, control the temperature of the water bath at 35°C, add 1g of surfactant sodium lauryl sulfate while stirring to obtain solution c, add solution b to solution c, and stir at 400rpm until two The methyl chloride was completely volatilized, the solid product was filtered under reduced pressure, the microcapsules were washed 3 times with distilled water, and dried to obtain 1.6 g of dry solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Peak particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com