Method for measuring polysaccharide content of medlar extracting solution

A technology of wolfberry extraction and polysaccharide content, which is applied in the measurement of color/spectral characteristics, etc., can solve the problems of long measurement period, influence photometric determination, strong corrosiveness of phenol concentrated sulfuric acid, etc., to improve operability and safety, eliminate wolfberry Effects of pigments, saving steps, and effects of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Pretreatment of wolfberry extract

[0041] Accurately absorb 8 mL of wolfberry extract obtained by ultrasonic extraction of wolfberry polysaccharides, add 20% Pb(Ac) 2 The protein was removed from the solution, until the precipitation was complete, 10% Na was added 2 SO 4 Remove lead from the solution, and dilute to 50mL with deionized water; after filtering, dilute to 100mL with deionized water.

[0042] (2) Preparation of test solution

[0043] a. Take 20 mL of the solution obtained in step (1), and dilute to 50 mL with deionized water to obtain the reducing sugar test solution.

[0044]b. Take 20mL of the solution obtained in step (1), add 10mL (1+1) hydrochloric acid, hydrolyze it in a water bath at 80°C for 15min, take it out and cool it to room temperature quickly, add dropwise a phenolphthalein indicator, and adjust to neutral with 30% NaOH solution properties, the volume was adjusted to 50mL with deionized water to obtain the total sugar test solution. ...

Embodiment 2

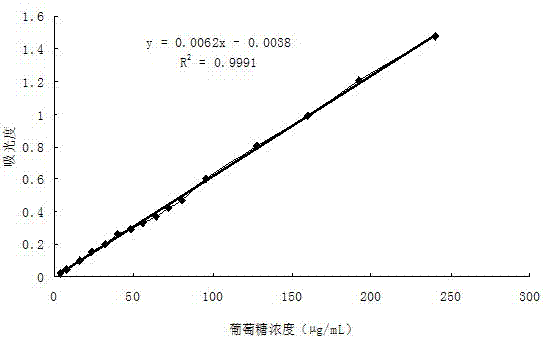

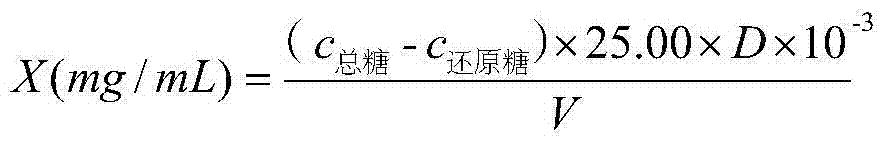

[0071] Accurately absorb 20mL of the wolfberry extract obtained by the hot water extraction method, and the quantitative detection method is the same as in Example 1. The absorbance value of the reducing sugar test solution is 0.632, and the absorbance value of the total sugar test solution is 0.684, which is substituted into the wolfberry extract The formula for calculating the polysaccharide content is available, and the polysaccharide content is 2.62mg / mL.

Embodiment 3

[0073] Accurately absorb 15 mL of the wolfberry extract obtained by the enzymatic method, and the quantitative detection method is the same as in Example 1. The absorbance value of the reducing sugar test solution is 0.095, and the absorbance value of the total sugar test solution is 0.142, which is substituted into the polysaccharide content in the wolfberry extract According to the calculation formula, the available polysaccharide content is 3.16mg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com