Double-stage rigid tooth surface cycloid steel ball planetary gear reducer

A planetary reducer, cycloid steel ball technology, applied in mechanical equipment, belts/chains/gears, transmission parts, etc., can solve the problems of high manufacturing and assembly accuracy requirements, increasing manufacturing process difficulty, insufficient transmission rigidity, etc. , to achieve the effect of reducing the volume, small heat treatment deformation of the tooth surface, and high transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

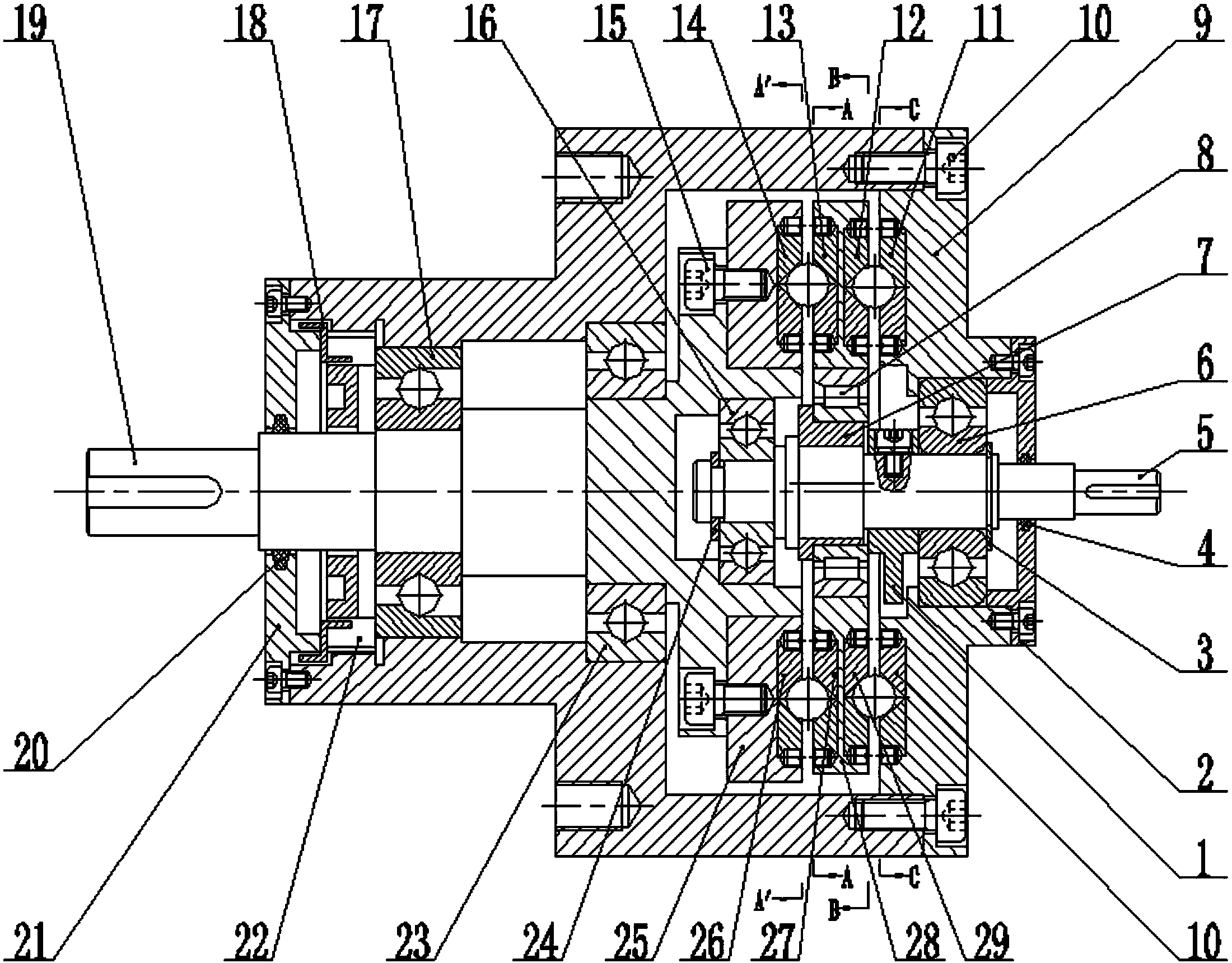

[0022] The accompanying drawing discloses the specific structure of an embodiment of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

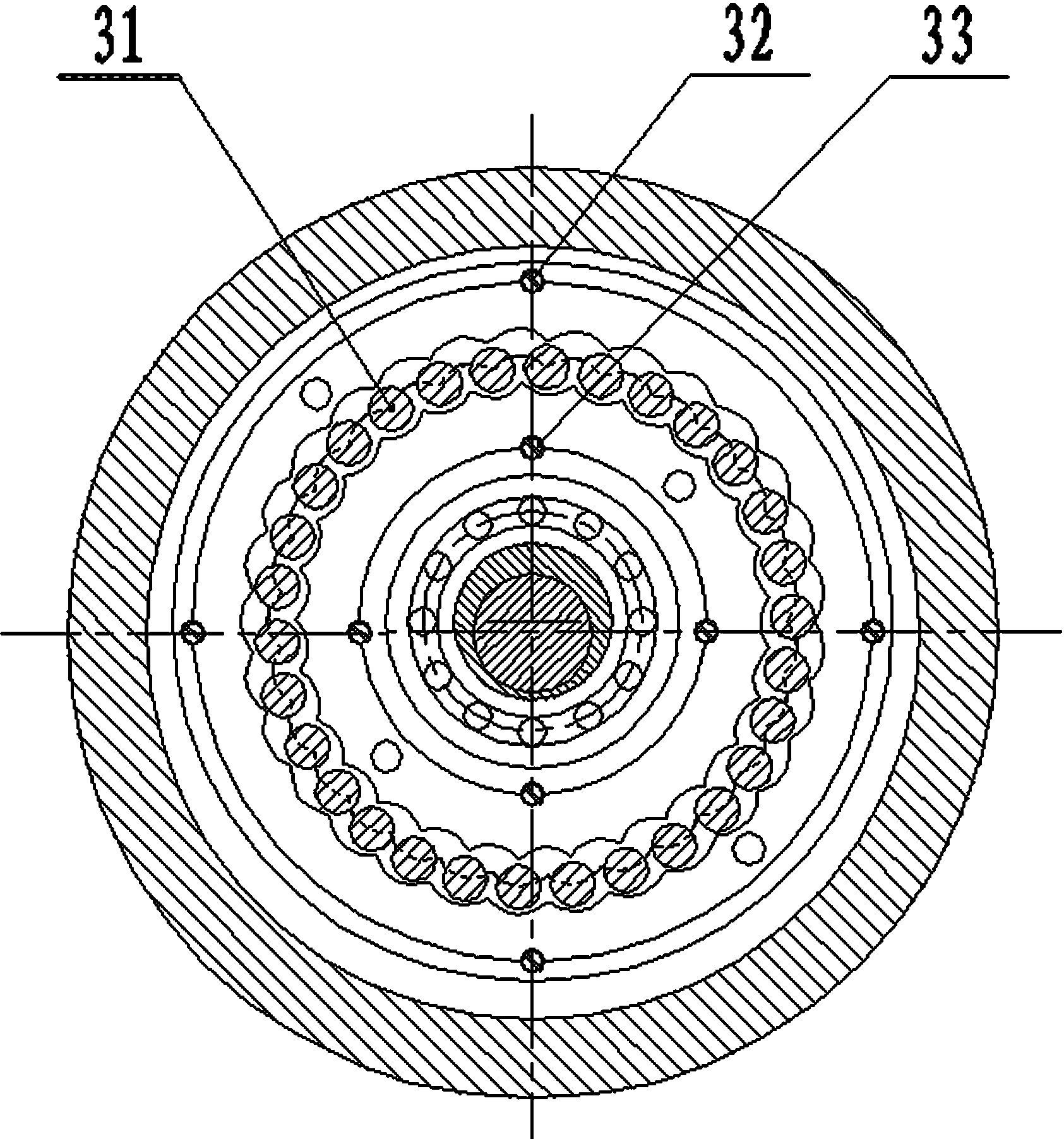

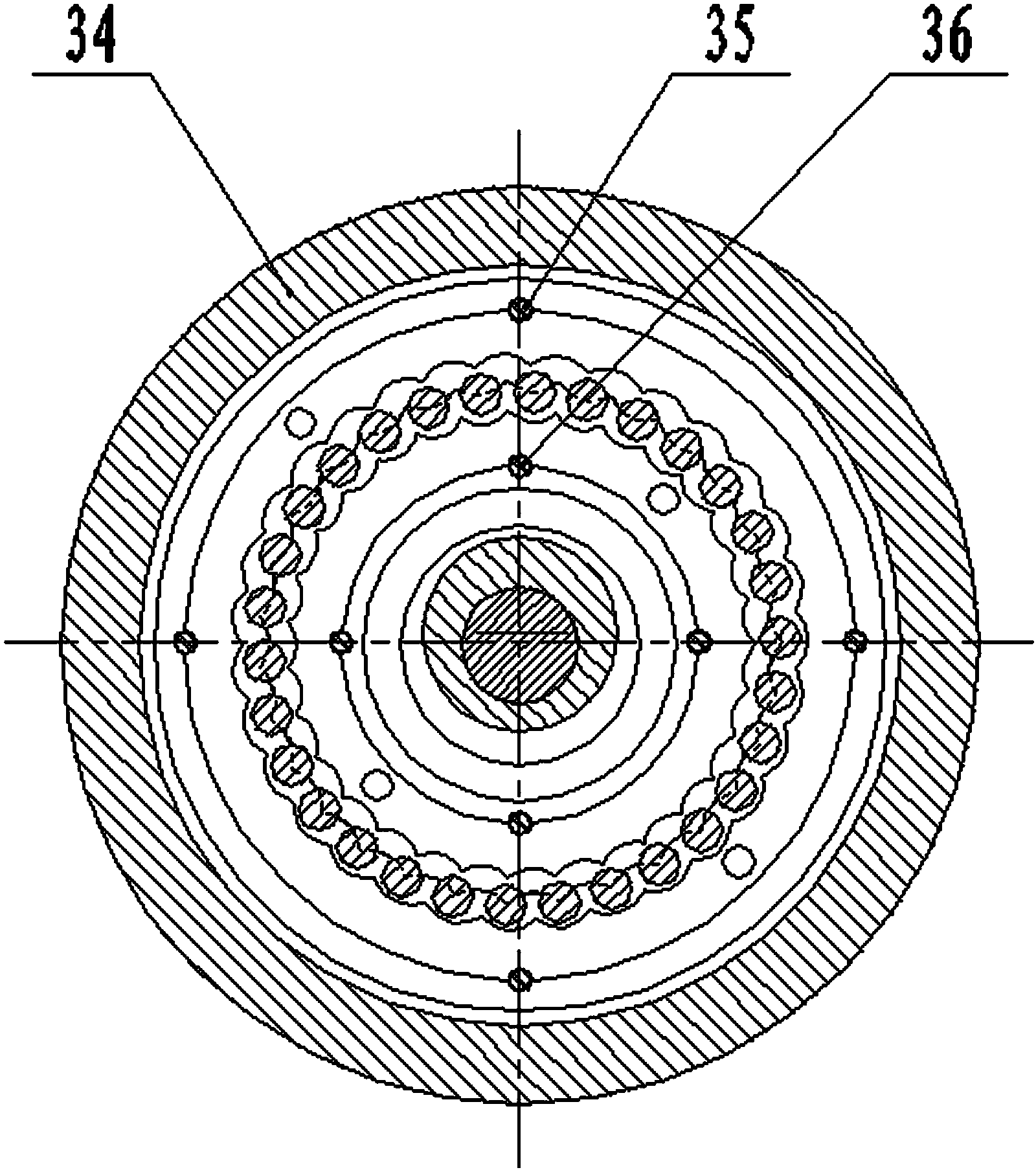

[0023] Figure 1 to Figure 5 The two-stage hard tooth surface cycloidal steel ball planetary reducer shown includes a balance weight 1; a right bearing end cover 2; a shaft circlip 3, a felt ring oil seal 4; an input shaft 5; Set 7; rotating arm bearing 8; end cover 9; screw group 10; hypocycloid outer disk 11; epicycloid outer disk 12; epicycloid outer disk 13; hypocycloid outer disk 14; screw group 15; input shaft Left support bearing 16; output shaft left support bearing 17; stop washer 18; output shaft 19; felt ring oil seal 20; left bearing end cover 21; Center plate 25; hypocycloid inner disc 26; epicycloid inner disc 27; planetary disc 28; epicycloid inner disc 29; hypocycloid inner disc 30; steel ball group 31; set screw group 32; Screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com