Multi-thread yarn spindle for yarn twisting machine

A twisting machine and twisting spindle technology, which is applied in the field of multifilament twisting spindles, can solve the problems of reducing the efficiency level of the twisting machine and damaging the program reliability, etc., and achieve the effects of increasing program reliability, long service life, and equal tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

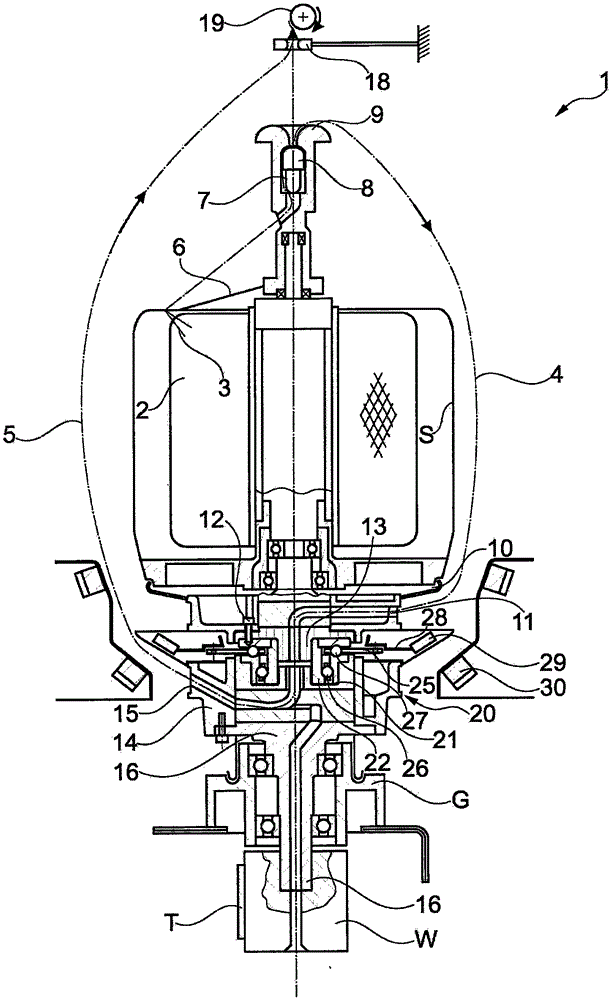

[0041] figure 1 A multifilament spindle according to the invention is shown. The yarn 3 is unwound from the package 2 and guided through the rotating flyer 6 to the braking zone 7 . After being pre-braked by the cabin-type yarn brake 8, the yarn 3 leaves the flyer 6 via the upper round head 9 and is guided to the upper twisting cup 10 around the vertical spindle disc S as an inner balloon 4.

[0042] Here the yarn 3 enters the upper yarn path 11 of the upper twisting cup 10 and is guided to the twisting cup 14 via a detour in the center of the multifilament spindle 1 . The yarn 3 is in turn deflected via the lower yarn path 15 in the lower twisting cup 14 and then guided upwards, as the outer balloon 5 , around the spindle disk S and at the same time around the inner balloon 4 .

[0043] Above the multifilament spindle 1 , the yarn 3 is now guided from the balloon yarn guide 18 to the rewinding device 19 as the yarn rotates.

[0044] During passage through the upper twistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com