A vertical vibration experimental device with force-controlled loading and variable layout

A vertical and layout technology, applied in the field of vertical vibration experimental devices, can solve the problems of small number of equipment, insufficiency, small working stroke, etc., to achieve low cost of construction and use, convenient installation and disassembly, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

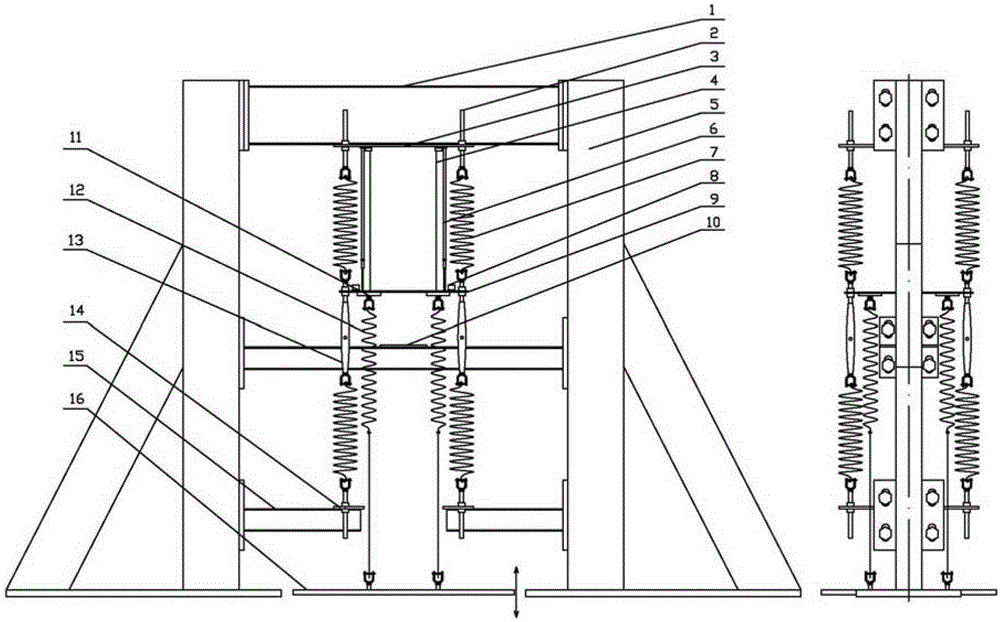

[0041] like figure 1 Shown, the structure of the present invention is as follows:

[0042]The main structure of a fixed portal steel frame is composed of two vertical supporting columns 5 and three sections of beams connected by screws, and the materials are standard I-shaped steel (25b) and steel plates. Install the top structure 3 of the fixed structure spring on the top beam 1 of the portal steel frame, and reserve the spring adjustable connection port 2 for fixed installation on it, and install two cantilever beams 15 at the bottom of the portal steel frame, A structural steel plate 14 is installed on it in a direction perpendicular to it, and an adjustable connection port 2 for fixing and installing a spring is also reserved on the steel plate 14 . These spring adjustable connection ends facilitate the adjustment of the structural spring 7 during the experiment, so that the distance between the two springs meets the specified elongation, so as to ensure the spring stiffn...

Embodiment 2

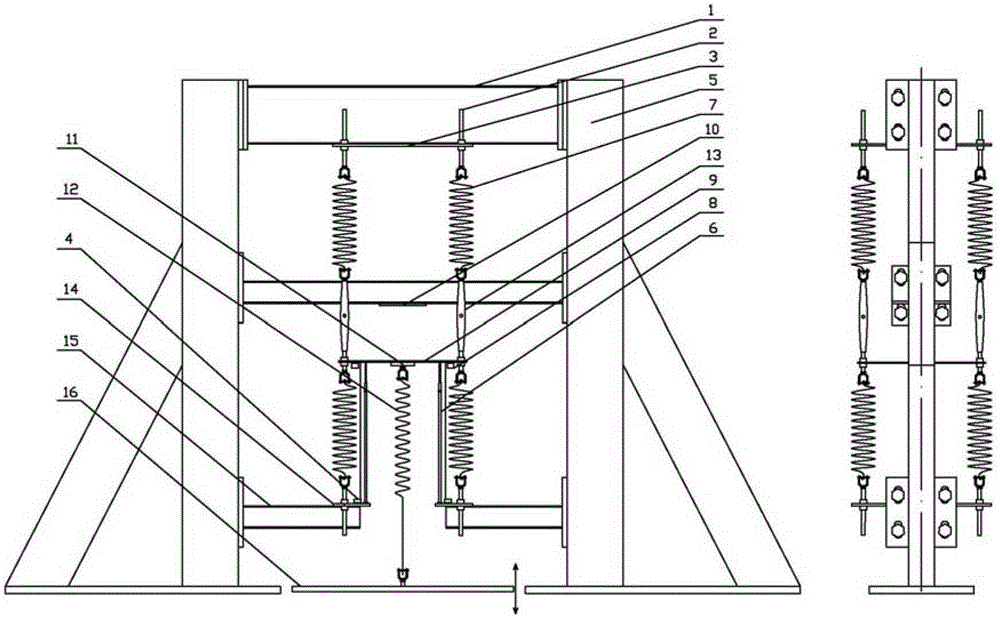

[0066] In order to meet the performance investigation of the special vibration reduction experimental device, it is sometimes necessary to install the vibration reduction experimental device on the bearing platform 10 on the upper part of the vibration structure model. For this reason, we have designed an experimental device with a different layout from Example 1, such as figure 2 shown.

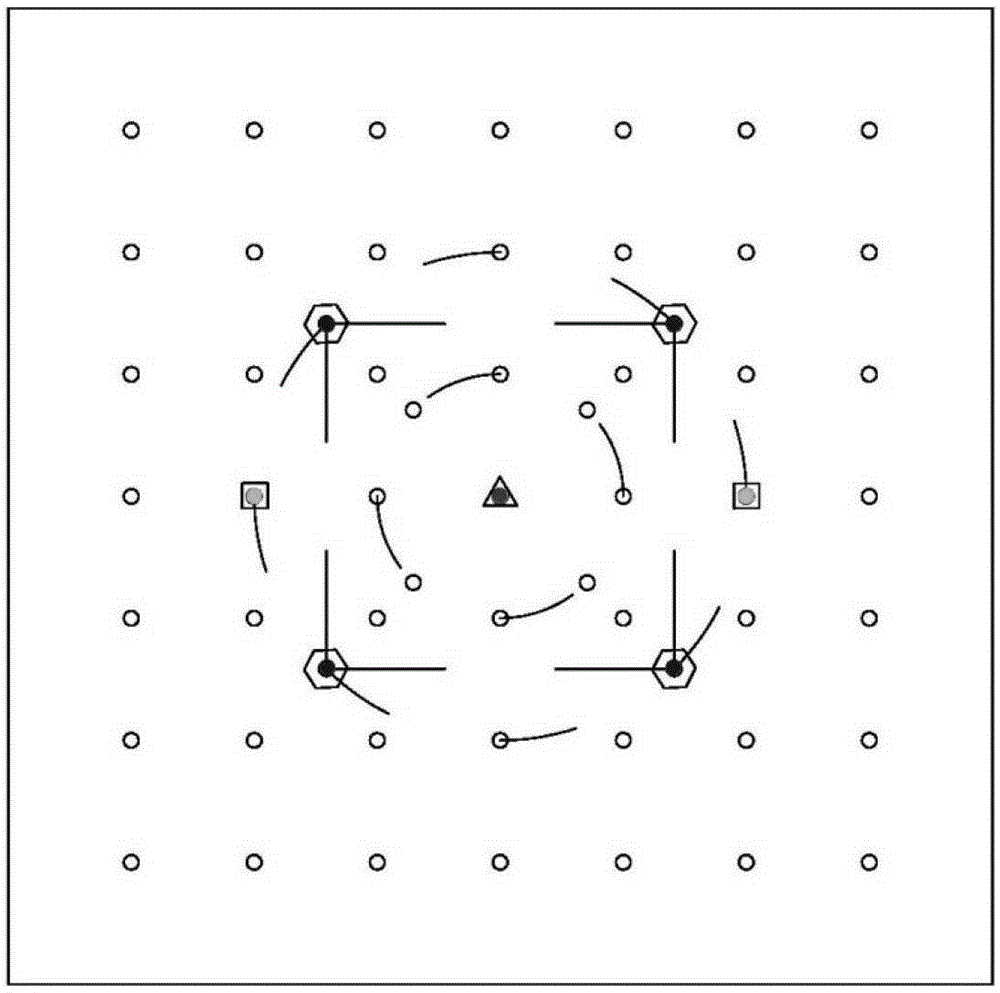

[0067] Due to the arrangement of the vibration reduction experimental device on the upper part of the vertical vibration plate 9 in this layout, it is convenient for us to implement various loading schemes on the vibration platform. Such as central single-force loading, side double-force loading, four-force loading, and even more force point loading to meet the needs of more accurate experiments to simulate real load conditions. For the layout of specific loading points, please refer to image 3 .

[0068] In the spring manufacturing process, due to the constraints of the manufacturing pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com