A thread winder for winding urethane elastic fiber

A silk roll and spandex technology, applied in the field of forming devices, can solve problems such as difficulty in ensuring the consistency of spandex silk cake formation, increased vibration and noise of the winding head, and increased difficulty in winding roll processing, so as to reduce equipment investment costs , Improve the efficiency of space use, and the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

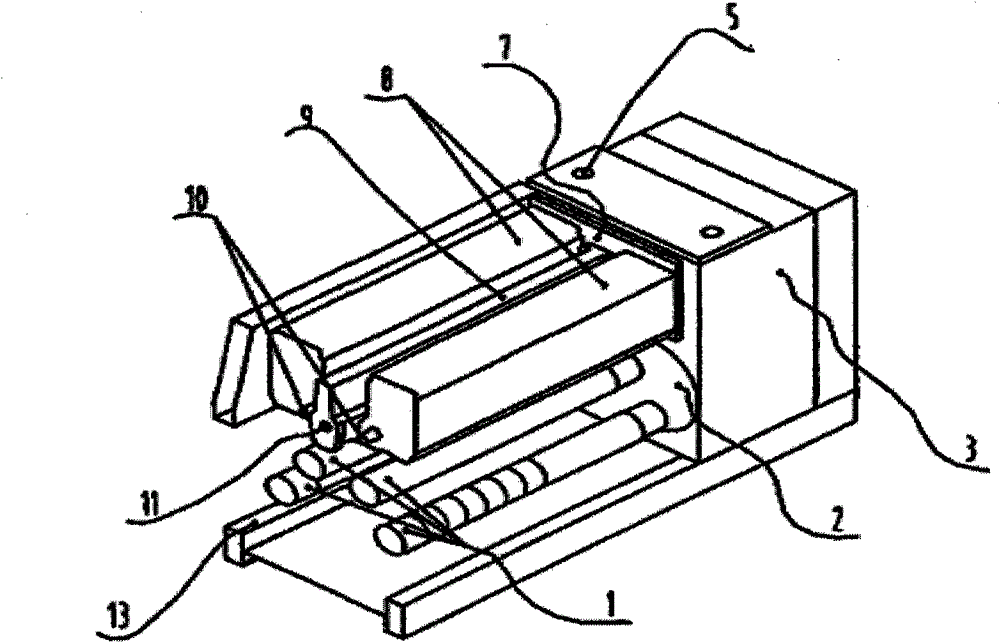

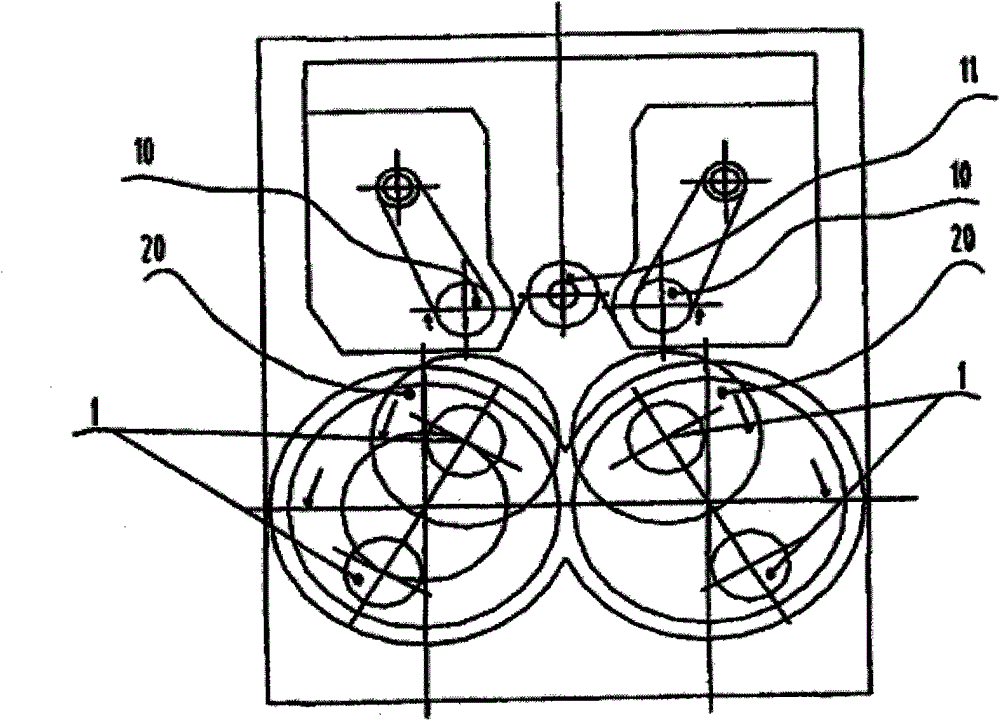

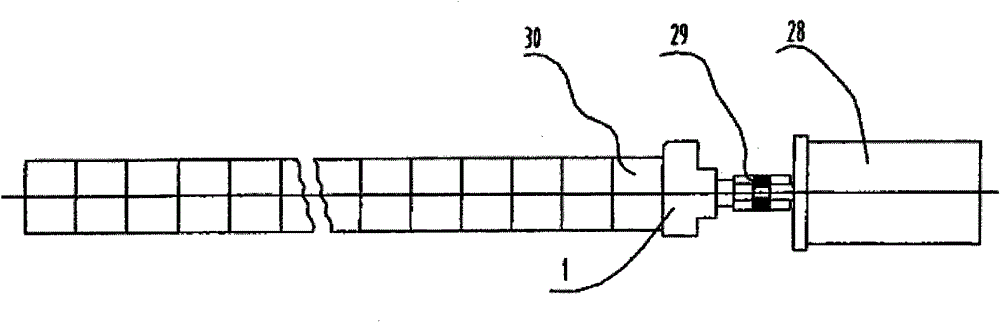

[0026] figure 1 is an isometric view of a winding head of the present invention, figure 2 is the transmission schematic diagram of the present invention, such as figure 1 and figure 2 As shown, the spandex yarn winding head of the present invention includes a power head 3 mounted on the frame 13, and the front end of the power head 3 is provided with two rotating disks, left and right, which can rotate around the central axis extending in the horizontal direction of itself. 2. On the front end surface of each turntable 2, two winding rollers 1 that can rotate around their own axes are arranged in parallel along the central axis of the turntable, and a slide box 7 is arranged above the turntable 2, and the rear end of the slide box 7 is set by setting The guide column 5 in the power head box and the lifting cylinder 6 for driving the slide box to move up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com