Improved silicon oxide ceramic core and preparation method thereof

A ceramic core, silicon oxide technology, applied in the core, casting molding equipment, casting and other directions, can solve the problems of poor high temperature performance, large firing shrinkage rate, etc., to improve the molding rate, good fluidity, and the preparation process. and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

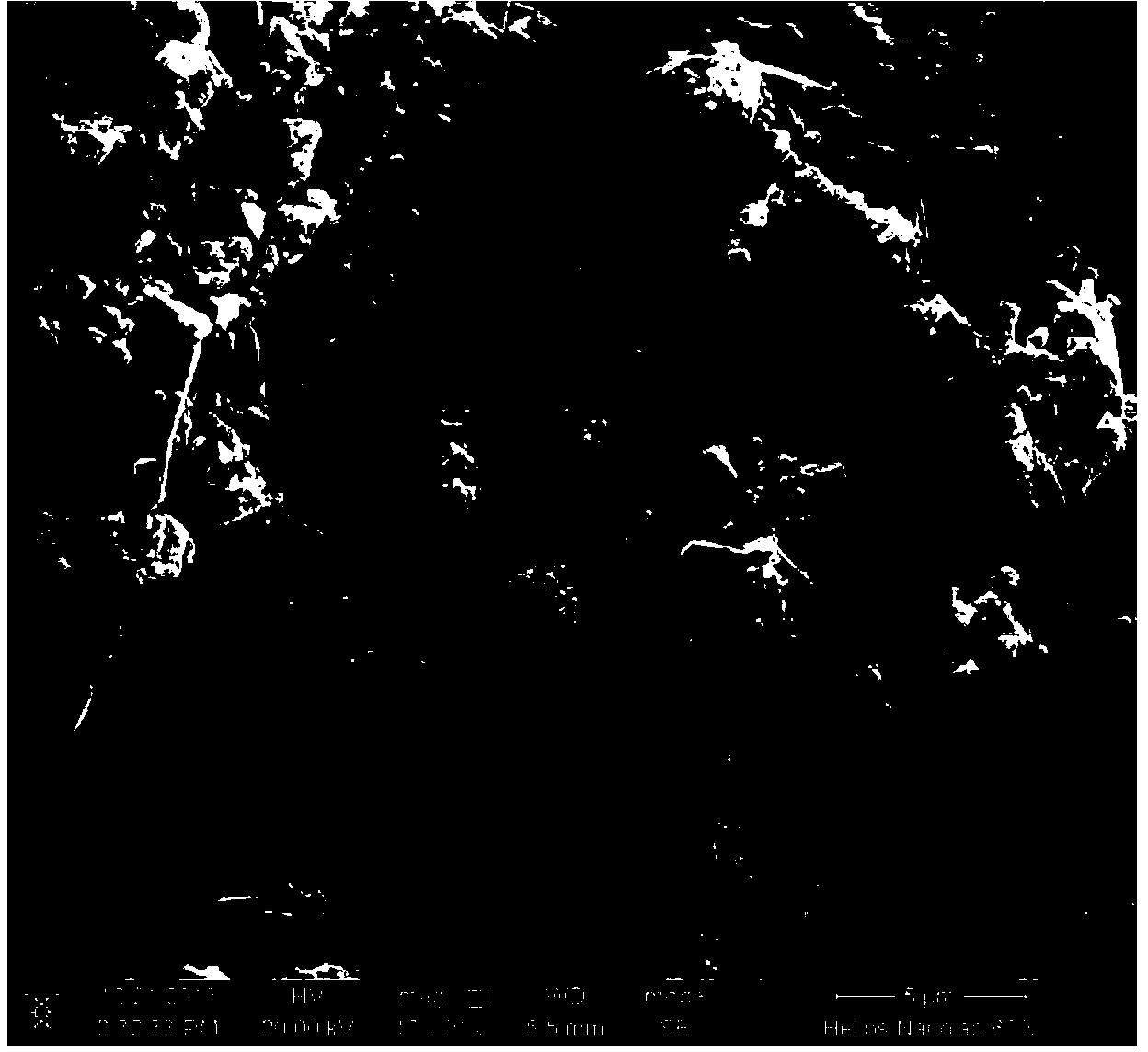

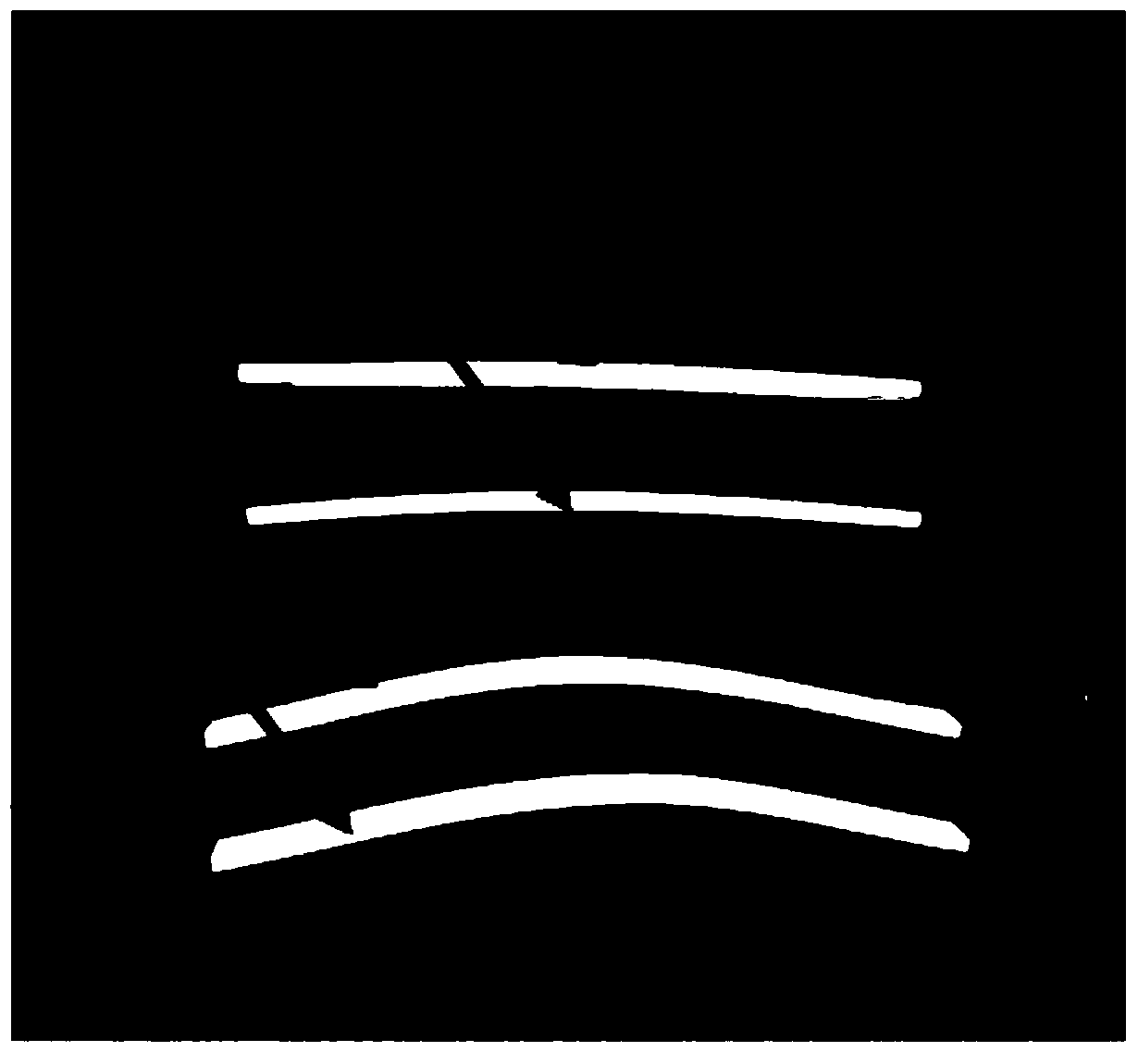

Image

Examples

specific Embodiment approach 1

[0018] Embodiment 1: An improved silicon oxide ceramic core in this embodiment is prepared from ceramic slurry and plasticizer; the mass ratio of the ceramic slurry to plasticizer is 100: (10-20 ); the ceramic slurry is formed by mixing 60-70 parts of quartz glass powder, 20-30 parts of zircon powder, 0.5-1.5 parts of analytically pure yttrium oxide and 5-15 parts of cristobalite in parts by mass; wherein The quartz glass powder is mixed by 200 mesh quartz glass powder, 300 mesh quartz glass powder and 400 mesh quartz glass powder, wherein the mass ratio of 200 mesh quartz glass powder to 300 mesh quartz glass powder is (4~6 ): 3, wherein the mass ratio of 200-mesh quartz glass powder to 400-mesh quartz glass powder is (4-6): 2; wherein the zircon powder is composed of 180-mesh zircon powder and 250-mesh zircon powder Mixed, wherein the mass ratio of 180 mesh zircon powder to 250 mesh zircon powder is (2-4):1; wherein the cristobalite is 300 mesh quartz; the plasticizer is mad...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of the ceramic slurry to the plasticizer is 100:15. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the ceramic slurry is composed of 64 parts of quartz glass powder, 25 parts of zircon powder, 1 part of analytically pure yttrium oxide and 10 parts by mass. Parts of cristobalite are mixed; wherein the quartz glass powder is mixed with 200 mesh quartz glass powder, 300 mesh quartz glass powder and 400 mesh quartz glass powder, wherein the 200 mesh quartz glass powder is mixed with 300 mesh quartz glass powder The mass ratio of the powder is 5:3, wherein the mass ratio of the 200-mesh quartz glass powder to the 400-mesh quartz glass powder is 5:2; wherein the zircon powder is composed of 180-mesh zircon powder and 250-mesh zircon powder powder, wherein the mass ratio of the 180-mesh zircon powder to the 250-mesh zircon powder is 3:1. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com