Preparation method of nano material modified poly piperazine amide nanofiltration membrane

A polypiperazine amide and nanomaterial technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of small flux, low interception selectivity, poor anti-corrosion performance, etc., and improve mechanical strength. , Improve membrane permeation flux, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Configuration mass concentration is 0.2% trimesoyl chloride (TMC) organic phase solution, wherein solvent is IsoparG, adds 0.01% lipophilic nano-titanium dioxide; Configuration mass concentration is 0.2% piperazine aqueous solution, then adding mass concentration is 0.05% The conductive nano-polyaniline is dispersed evenly by ultrasonic, the polysulfone support membrane is immersed in the piperazine aqueous solution for 120 seconds, and then the polysulfone support membrane is rolled with a rubber roller to remove the excess solution; after the solution is dry, it is mixed with the organic phase solution Contact for 20 seconds; put the membrane into a vacuum oven at 80° C. for 12 minutes, and dry to obtain a modified nanofiltration composite membrane. Use 2000ppm sodium sulfate aqueous solution, magnesium chloride, sodium chloride aqueous solution to test the initial performance of the membrane under the pressure of 1MPa. 2 SO 4 and MgCl 2 The desalination rate is 97....

Embodiment 2

[0018] Configuration mass concentration is the trimesoyl chloride (TMC) organic phase solution of 0.2%, and wherein solvent is IsoparG; Configuration mass concentration is the piperazine aqueous solution of 0.2%, polysulfone support membrane is put into piperazine aqueous solution and soaked 120 seconds, Then roll the polysulfone support membrane with a rubber roller to remove excess solution; after the solution is dry, contact with the organic phase solution just after ultrasonic dispersion for 20 seconds; put the membrane in a vacuum oven at 80°C for 12 minutes, and dry it to prepare Obtain nanofiltration composite membrane and use 2000ppm sodium sulfate aqueous solution, magnesium chloride, sodium chloride aqueous solution to test the initial performance of the membrane under 1MPa pressure. 2 SO 4 and MgCl 2 The desalination rate is 89.2% and 66.7%, the removal rate of NaCl is 30.7%, and the flux is 35.6L / h / m 2 .

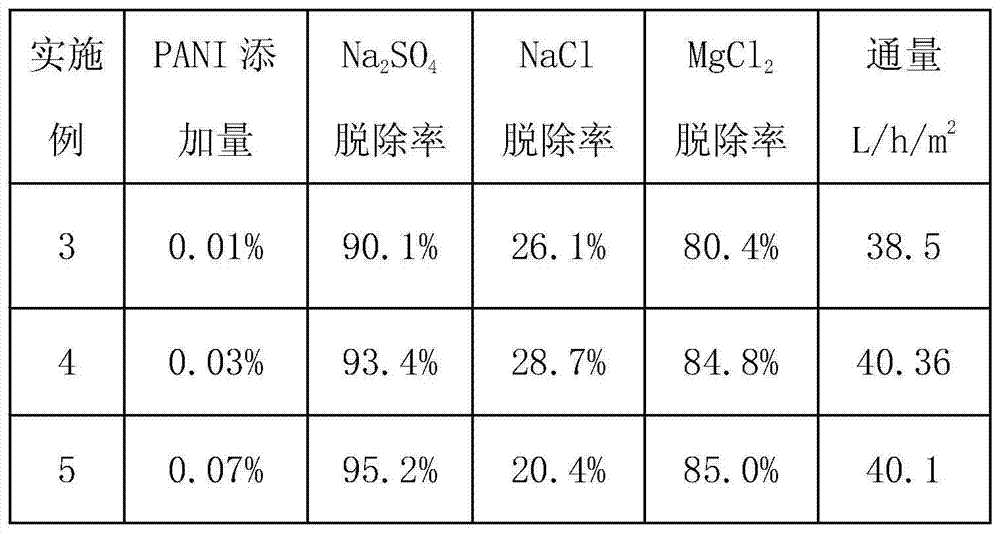

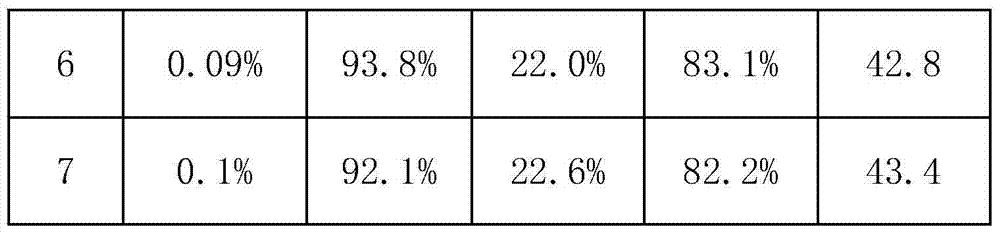

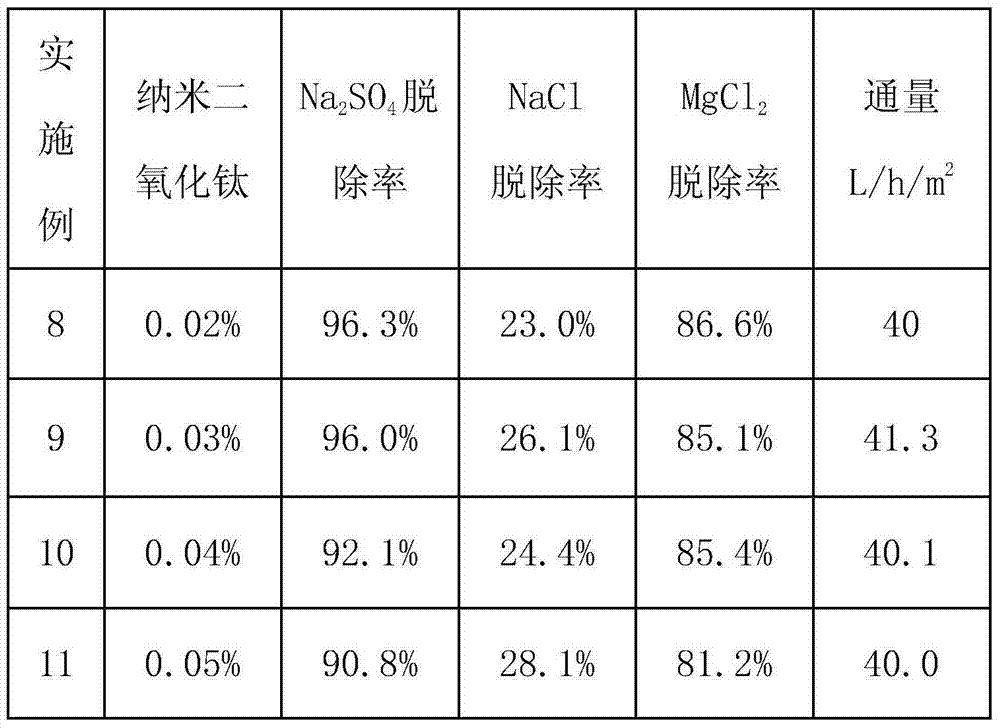

Embodiment 3-7

[0020] Change the addition amount of conductive nano-polyaniline (PANI) in the aqueous phase solution, and the other steps are the same as in Example 1 to prepare a composite film and test it. The results are shown in the following table:

[0021]

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com