Production process for producing wheat hydrolyzed protein by wet gluten

A wheat hydrolyzed protein and production process technology, applied in the field of wheat hydrolyzed protein production process, can solve the problems of energy consumption, product nutritional value decline, vitamin damage, etc., and achieve the effects of improving production efficiency and product quality and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with reference to the drawings and specific embodiments.

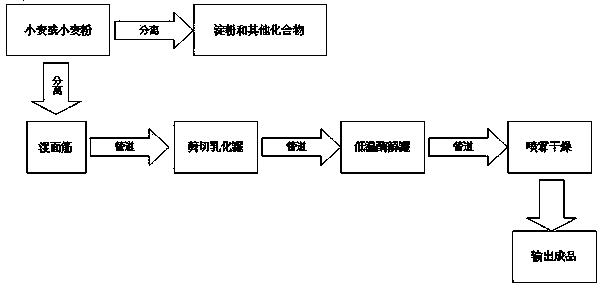

[0012] Such as figure 1 As shown, the present invention is a production process for producing wheat hydrolyzed protein from wet gluten. The production process steps are as follows: ① Using wheat or wheat flour as raw materials, remove starch and other carbohydrates in a separator to obtain protein components Obtain wet gluten; ②The wet gluten is transported through the pipeline to the shearing emulsification tank for de-viscous shearing and enzymatic hydrolysis and liquefaction, while sampling to determine the quality and dry content; ③The viscosity of the wet gluten after de-tack-cutting is reduced, Transport it to a low-temperature enzymatic hydrolysis tank, and carry out enzymatic hydrolysis treatment at a temperature of 45°C-65°C and a pH value of 6.0-8.0 for 2-8 hours; ④After full enzymolysis and liquefaction, the protein in the wheat protein in the wet g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com