A flame cutting device

A technology of flame cutting and flame temperature, which is applied in the field of mechanical processing, can solve problems such as high production cost, waste of manpower and financial resources, and influence on the uniformity of steel plate performance, and achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are preferred embodiments of the present invention, which are only used to explain the application rather than limit it.

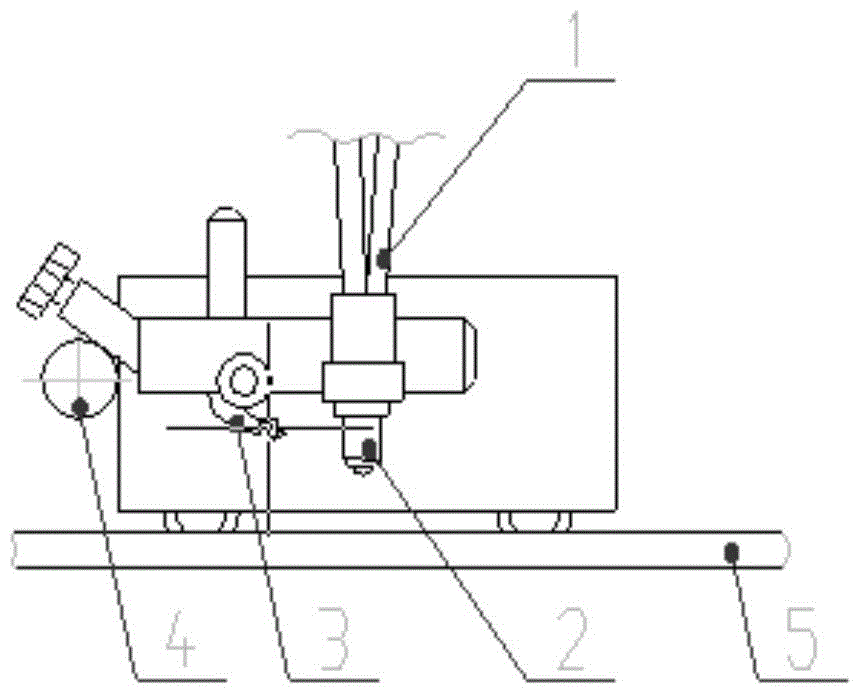

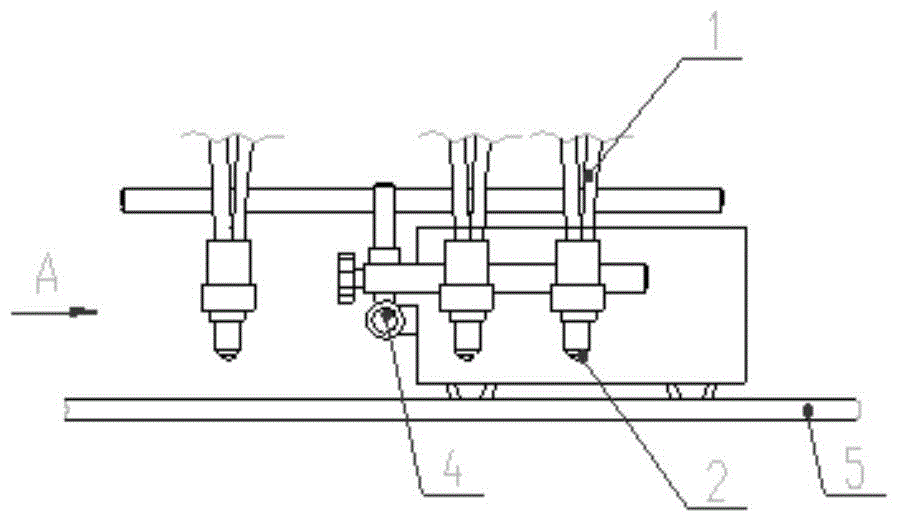

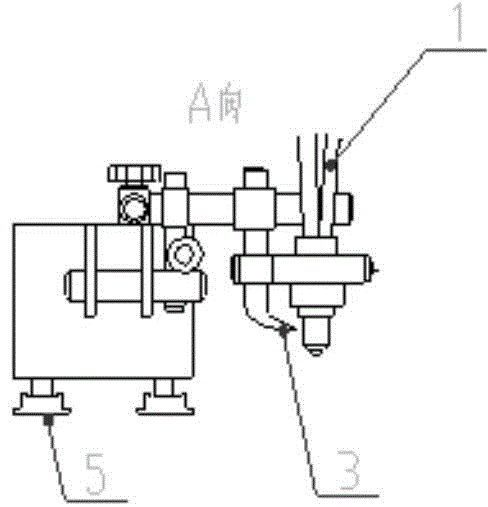

[0019] See attached drawing 2, three flame cutting torch heads work simultaneously on the same cutting machine; the three torch heads are arranged in sequence at a certain distance, and work synchronously on a straight line. Preheating and postheating are carried out respectively, and the middle gun is used for fixed-length cutting; the first flame cutting gun head and the third flame cutting gun head arranged horizontally can be adjusted according to the thickness of the steel plate by adjusting the distance between the middle cutting gun head and the Gas output to adjust the preheating temperature.

[0020] The flame temperature of the first flame cutting torch head is 450 degrees Celsius, the flame temperature of the second flame cutting torch head is 2850 degrees Celsius, and the flame temperature of the third flame cutting torch h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com