Ultrasonic welding equipment for fans, as well as usage method and application thereof

An ultrasonic welding and ultrasonic technology, applied in welding equipment, non-electric welding equipment, mechanical equipment, etc., can solve the problems of high noise, influence of motor load changes, and low processing difficulty, so as to reduce costs, maximize benefits, improve product quality and The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing, the present invention will be further described by example:

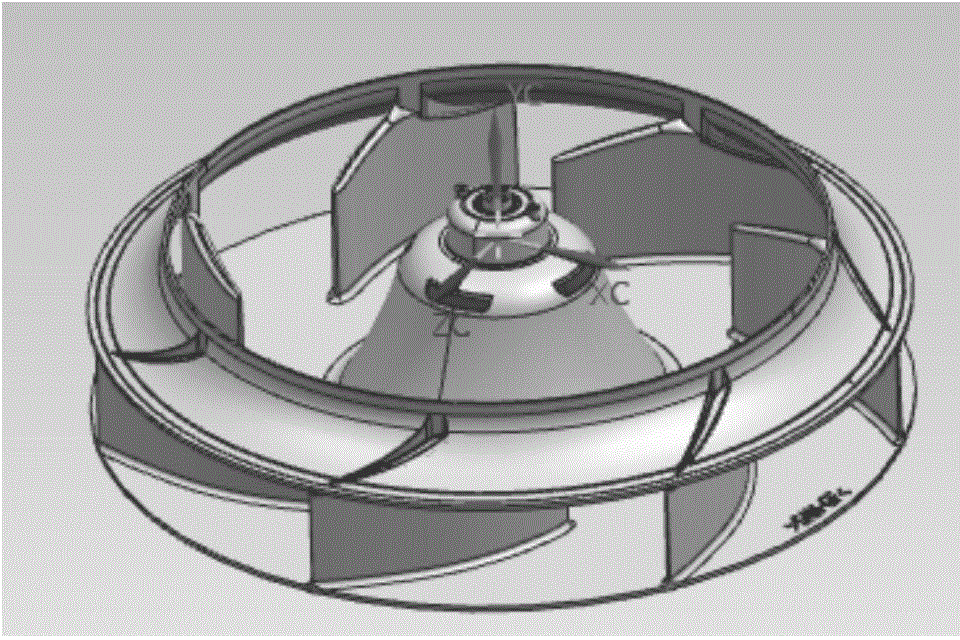

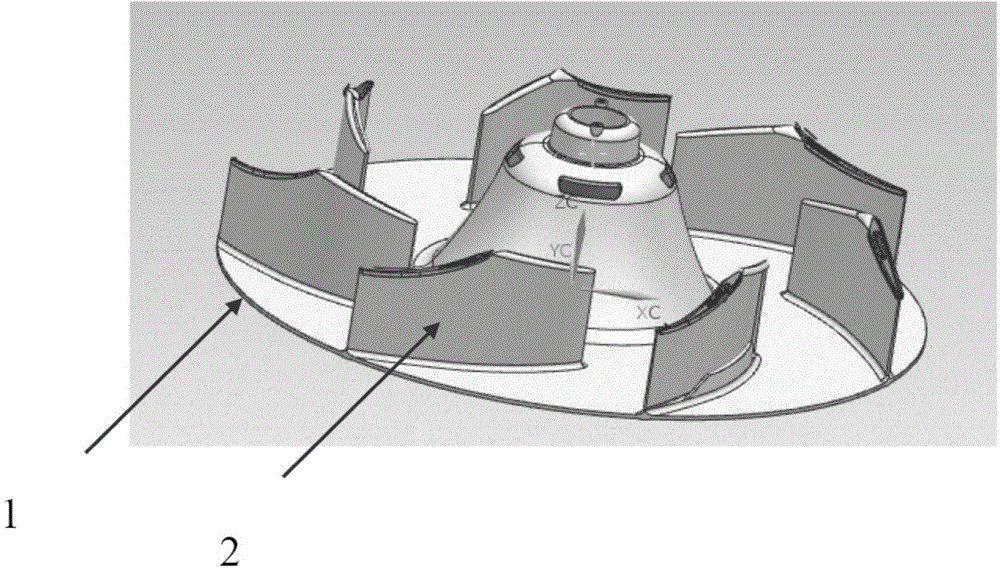

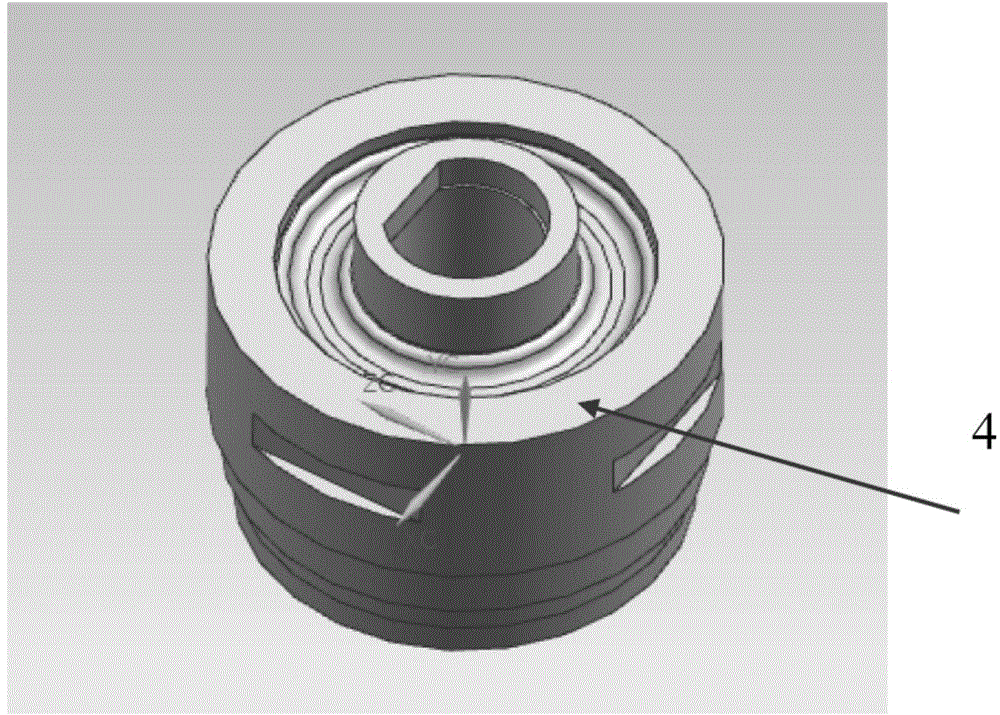

[0048] As shown in the accompanying drawings, the fan of the present invention is composed of a hub 1, fan blades 2, air guiding ring 3, and rubber bushing 4, wherein the hub 1, fan blades 2 and rubber bushing 4 are integrally injection molded. The fan of the present invention is provided by positioning the hub integrally formed by injection molding on the wind guide ring and ultrasonic welding.

[0049] Specific operation steps:

[0050] 1. First fix the air guide ring on the positioning mold (see 9)

[0051] 2. Place the hub in the vane groove of the air guide ring according to the order of the vanes (see 10)

[0052] 3. Adjust the distance and angle between the welding head and the hub, adjust the current, welding time, air pressure and other parameters of the welding machine, and manually test whether the welding hair wave is normal. (see 5, 6)

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com