A kind of metal foil high temperature sealing method

A high-temperature sealing, metal foil technology, applied in pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of high sealing surface temperature, large deformation, uneven distribution of pressing force on the sealing surface, etc. Reliability, the effect of reducing the effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

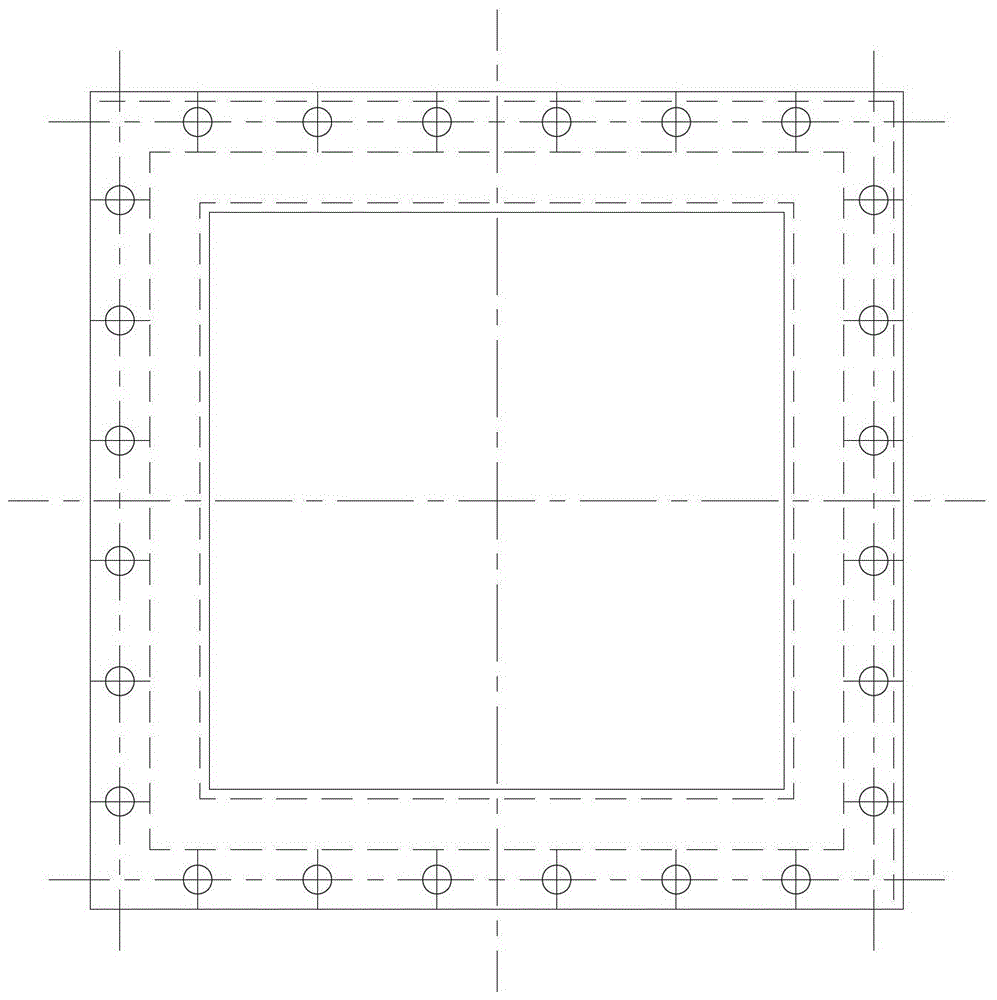

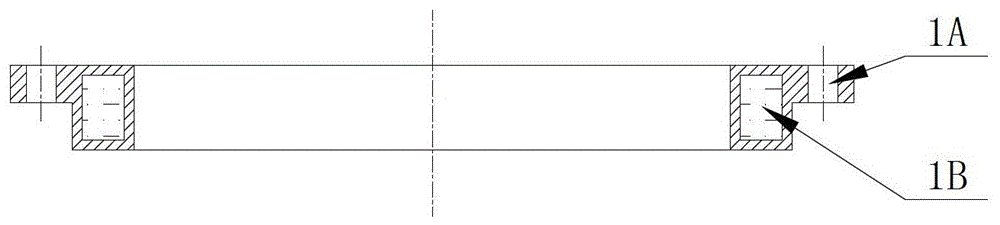

[0048] 1) Weld the active cooling connecting flange [3E] on the sealing end face of the required connection, and reserve a cooling liquid circulation channel inside the connecting flange [3E], which is used to circulate the cooling liquid to cool the connecting flange; connection method The thickness of the blue plate [3E] is H1, and the threaded holes [1A] with a diameter D1 are uniformly distributed circumferentially at a distance L2 at a distance from the outer ring L1, and a cooling groove with a width of L4 and a depth of H2 is opened at a position distance from the inner ring L3 [1B]; wherein H1=50mm, L1=15mm, L2=50mm, D1=10mm, L3=10mm, L4=10mm, H2=30mm.

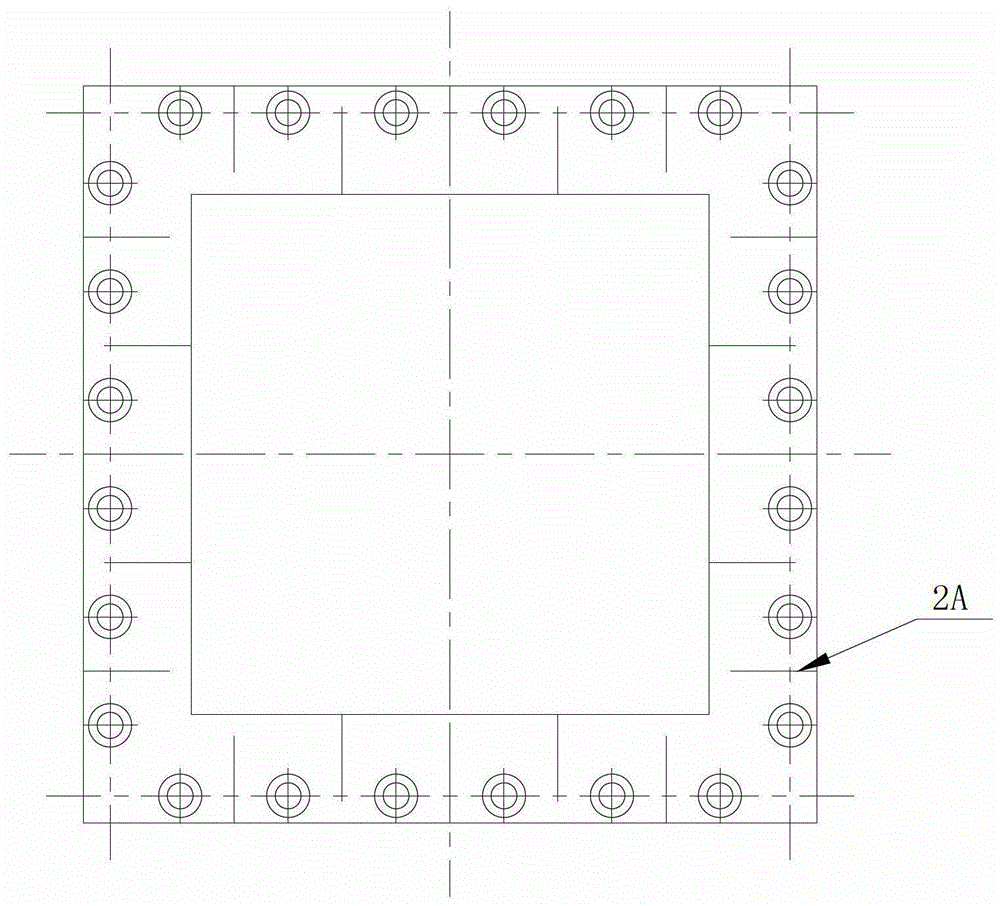

[0049]2) Prepare the frame pressing plate [3A] with the same external dimensions and opening dimensions as the connecting flange [3E], and the thickness is H3, and make slits on it, and all the slits [2A] from the frame pressing plate [3A] ] Start from the inner ring, cut outwards, each slit [2A] is located on the symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com