Process for preparing cytisine from thermopsis lanceolata glasses and seeds

A technology for the preparation process of Magus bean grass, applied in the direction of organic chemistry, etc., can solve the problems of product purity and yield not meeting the requirements of the pharmaceutical industry, not having mass production practicability, and staying in the laboratory, etc., to achieve product purity. The effect of high, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

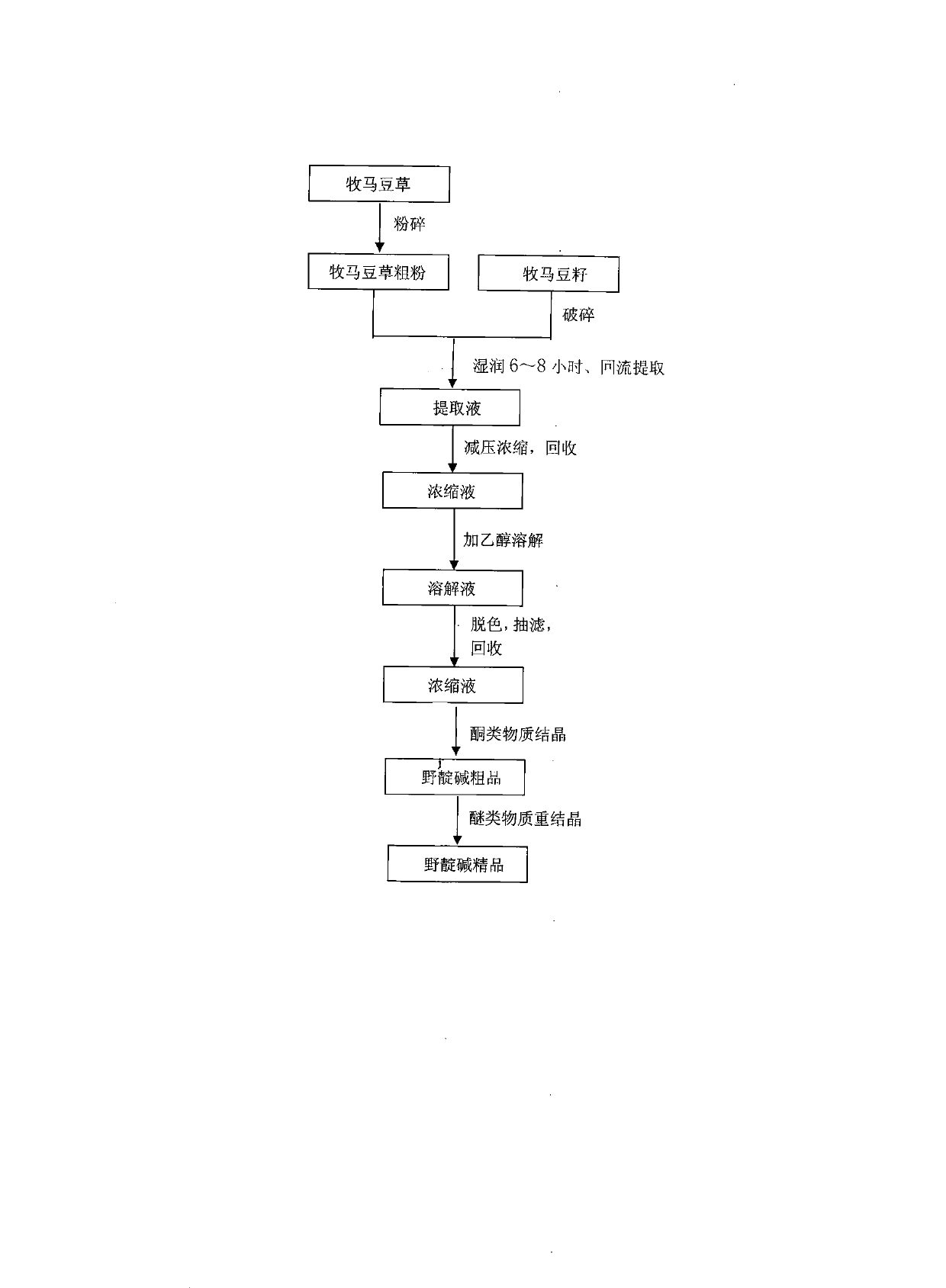

Image

Examples

Embodiment 1

[0023] Grind the dried rambean grass into coarse powder or break rambean seeds, weigh 100kg of rambean grass powder or 100kg of broken rambean seeds, put it into an extraction container, and moisten it with 3% sodium hydroxide solution After 7 hours, add chloroform to reflux for extraction, combine the extracts, and concentrate under reduced pressure to recover chloroform, then add ethanol for dissolution, and the solution is decolorized by alumina (Al 2 o 3 ), filtered, recovered ethanol under reduced pressure, added acetone to crystallize to obtain 8.2 kg of crude cydidine, and then recrystallized with petroleum ether to obtain 6.6 kg of cydidine fine product, with a content of 98.5%.

Embodiment 2

[0025] Grind the dried herb bean grass into coarse powder or crush herb bean seeds, weigh 120kg of herb bean grass powder or 120kg of broken herb bean seeds, put them into an extraction container, moisten with 2% potassium hydroxide solution After wetting for 8 hours, add chloroform to reflux for extraction, combine the extracts, and concentrate under reduced pressure to recover chloroform; add ethanol to dissolve, and the solution is decolorized by alumina (Al 2 o 3 ), filtered, recovered ethanol under reduced pressure, added acetone to crystallize to obtain 9.8 kg of crude cydidine, and then recrystallized with petroleum ether to obtain 7.9 kg of cydidine fine product, with a content of 98.8%.

Embodiment 3

[0027] Grind the dried herb bean grass into coarse powder or crush herb bean seeds, weigh 100kg of herb bean grass powder or 100kg of broken herb bean seeds, put them into an extraction container, and moisten them with 3% sodium hydroxide solution After wetting for 6 hours, add chloroform to reflux for extraction, combine the extracts, and concentrate under reduced pressure to recover chloroform; add ethanol to dissolve, decolorize the solution through activated carbon, filter, recover ethanol under reduced pressure, add acetone to crystallize to obtain 8.0 kg of crude cylindine, Add diethyl ether and recrystallize to obtain 6.4kg of cydidine fine product, the content of which is 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com