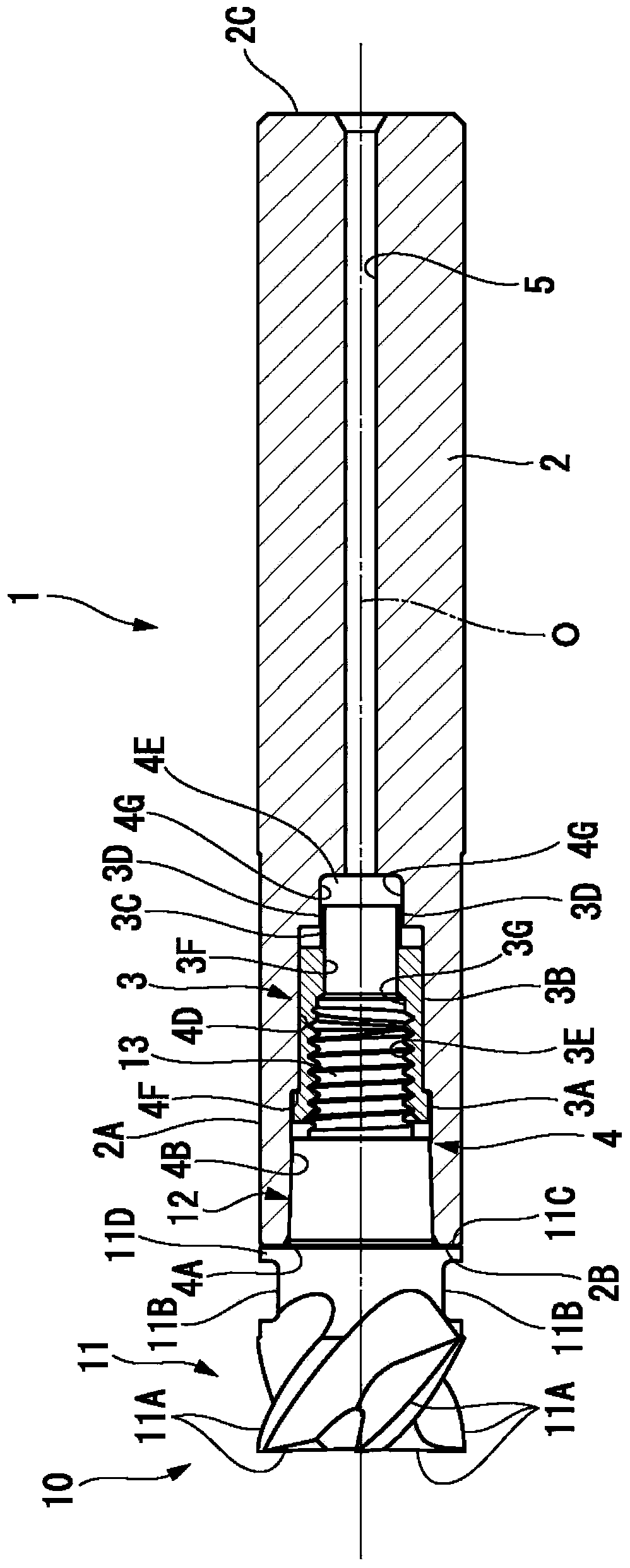

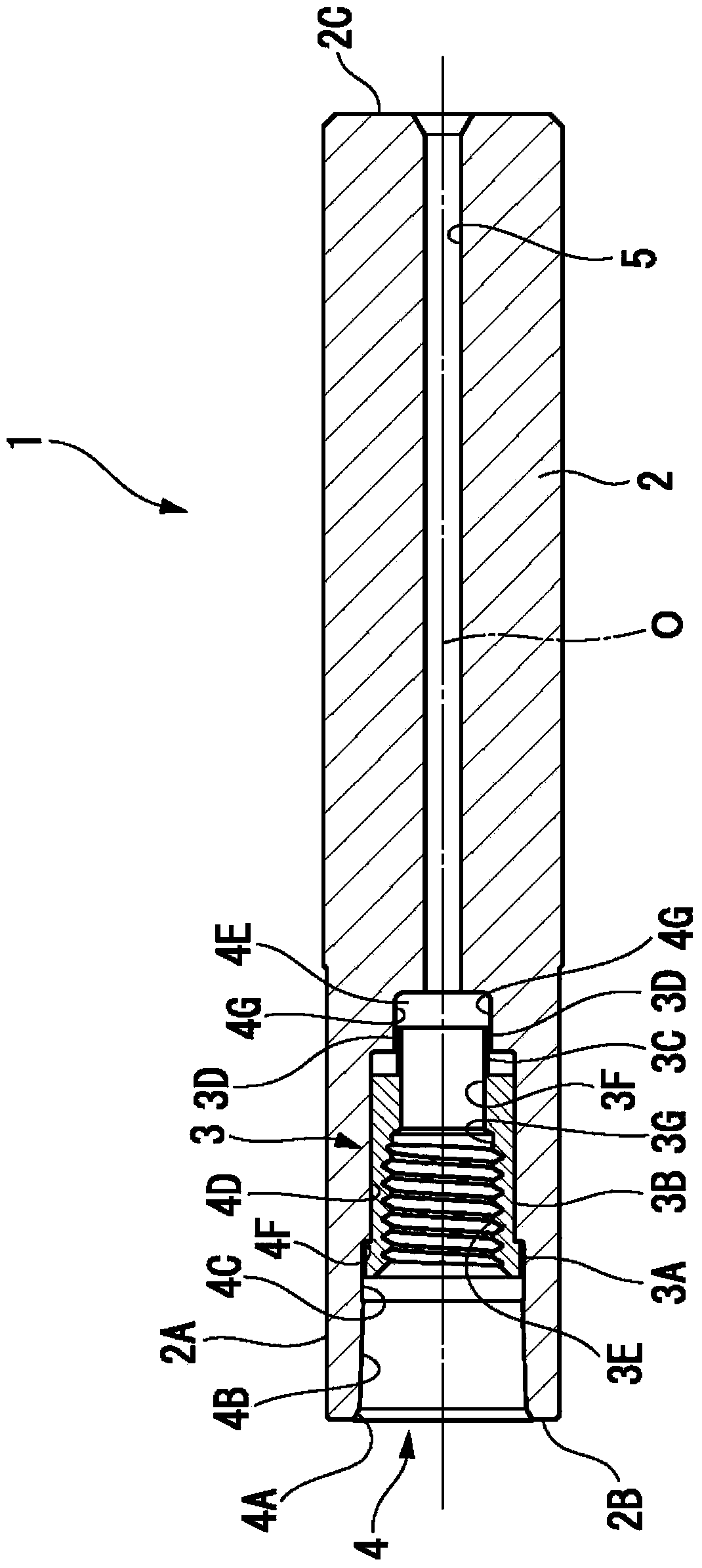

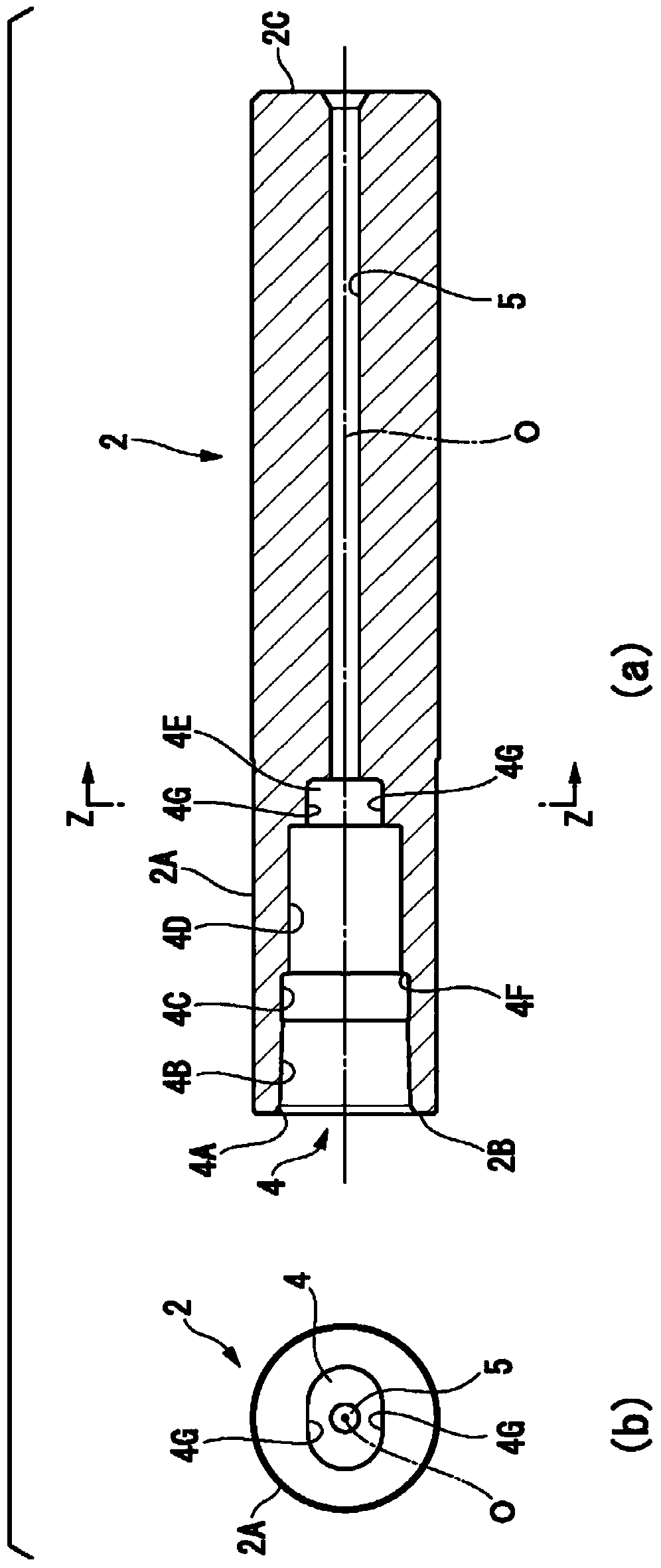

Head replacement-type cutting tool

A cutting tool, exchange technology, applied in the direction of manufacturing tools, tool workpiece connection, metal processing equipment, etc., can solve problems such as breakage, cutting head breakout, cutting head idling, etc., to improve fracture toughness, reliable contact pressure, and improve thermal conductivity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0124]Next, the ratio d / D1 of the inner and outer diameters of the tool holder 1 and the expansion ratio of the outer diameter (D2-D1) / D1×100 (%) in the present invention will be described with examples. In this example, based on the head replaceable cutting tool (head replaceable end mill) of the above-mentioned embodiment, the holder 1 in the state before the mounting part 12 of the cutting head 10 is first fitted In the two head exchangeable cutting tools in which the outer diameter D1 of the front end of the holder main body 2 is 0.01 m (10 mm) and 0.02 m (20 mm), the inner diameter d of the opening side of the above-mentioned mounting hole 4 of the fitting portion 4B is The allowable torque with respect to the ratio d / D1 of the inner and outer diameters during the change is calculated in the following two cases, that is, as the minimum for cutting, the stress generated in the tool seat 1 is designed to be 100MPa (for example, as For light cutting), and as the upper limit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com